Laser cutting has always been the most widely used technology in laser processing. Pulsed lasers are suitable for metal materials, and continuous lasers are suitable for non-metal materials. The latter is an important application field of laser cutting technology. Combined with computer-controlled automatic equipment, the laser beam has unlimited profiling cutting capabilities, and the cutting trajectory is easy to modify. Laser cutting has no mechanical deformation, no tool wear, and it is easy to realize automated production.

Laser cutting is widely used in sheet metal processing, metal processing, advertising production, kitchenware, automobiles, lamps, saw blades, elevators, metal crafts, textile machinery, food machinery, glasses production, aerospace, medical equipment, instrumentation and other industries. Especially in the sheet metal processing industry, it has replaced traditional processing methods and is deeply favored by industry users.

1. Laser cutting process

Laser cutting uses a high-power density laser beam to irradiate the material to be cut, so that the material is quickly heated to vaporization temperature, and evaporates to form holes. As the beam moves on the material, the holes continuously form a narrow width (such as about 0.1 mm). Seam to complete the cutting of the material.

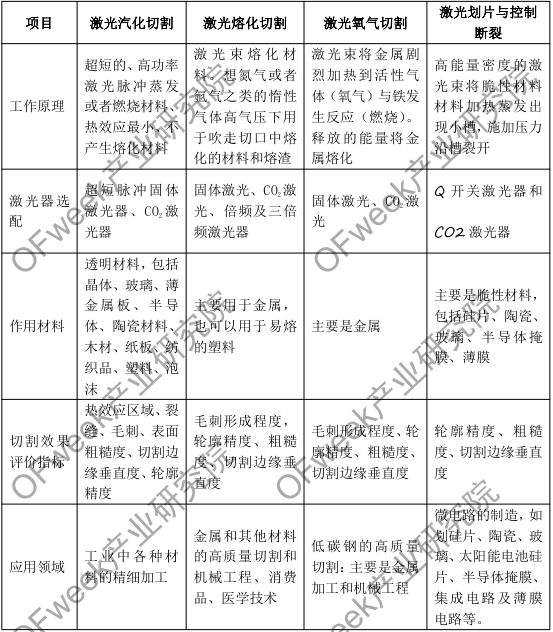

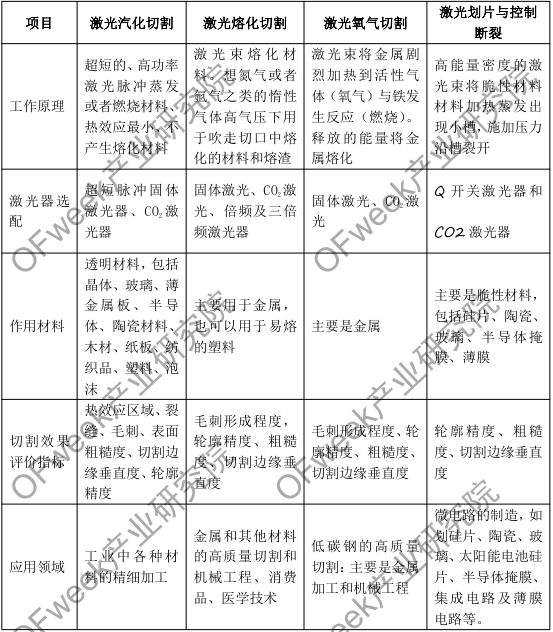

Laser cutting can be divided into four categories: laser vaporization cutting, laser melting cutting, laser oxygen cutting and laser scribing and controlled fracture.

1. Laser vaporization cutting

The high-energy density laser beam is used to heat the workpiece, so that the temperature rises rapidly, reaching the boiling point of the material in a very short time, and the material begins to vaporize and form vapor. The jetting speed of these vapors is very high, and at the same time as the vapor jets, cuts are formed in the material. The heat of vaporization of materials is generally very large, so a lot of power and power density are required for laser vaporization and cutting.

Laser vaporization cutting is mostly used for cutting extremely thin metal materials and non-metal materials (such as paper, cloth, wood, plastic, rubber, foam, etc.). Ultrashort pulse lasers allow this technology to be applied to other materials. The free electrons in the metal absorb the laser light and heat up violently. The laser pulse does not react with the molten particles and plasma, the material directly sublimates, and there is no time to transfer energy to the surrounding materials in the form of heat. When the picosecond pulse ablates the material, there is no obvious thermal effect, no melting and burr formation.

2. Laser melting and cutting

In laser melting and cutting, the metal material is melted by laser heating, and then non-oxidizing gas (Ar, He, N, etc.) is sprayed through a nozzle coaxial with the beam, and the liquid metal is discharged by the strong pressure of the gas to form an incision. Laser melting and cutting do not need to vaporize the metal completely, and the energy required is only 1/10 of that of vaporized cutting.

Laser melting cutting is mainly used for cutting some materials that are not easily oxidized or active metals, such as stainless steel, titanium, aluminum and their alloys, etc., and can also be used for cutting other fusible materials, such as ceramics.

3. Laser oxygen cutting (flame cutting)

The principle of laser oxygen cutting is similar to oxyacetylene cutting. It uses a laser as a preheating heat source and an active gas such as oxygen as the cutting gas. On the one hand, the blown gas reacts with the cutting metal to generate an oxidation reaction and release a large amount of oxidation heat; on the other hand, the molten oxide and melt are blown out of the reaction zone to form an incision in the metal. Because the oxidation reaction in the cutting process generates a lot of heat, the energy required for laser oxygen cutting is only 1/2 of the melting cutting, and the cutting speed is much faster than laser vaporization cutting and melting cutting. Laser oxygen cutting is mainly used for easily oxidized metal materials such as carbon steel, titanium steel and heat-treated steel.

4. Laser scribing and control fracture

Laser scribing uses a high-energy density laser to scan the surface of the brittle material, so that the material is heated to evaporate a small groove, and then a certain pressure is applied, and the brittle material will crack along the small groove. The lasers used for laser scribing are generally Q-switched lasers and CO2 lasers.

Controlled fracture is the use of the steep temperature distribution generated when the laser groove is carved, which generates local thermal stress in the brittle material, causing the material to break along the small groove.

2. Laser cutting process and equipment comparison

Chart 1: Comparison of different laser cutting processes (unit: set)

Source: OFweek Industry Research Institute

Three, analysis of the status quo of laser cutting machine market development

In modern industrial production, laser cutting is widely used in sheet metal, plastics, glass, ceramics, semiconductors, textiles, wood and paper and other materials processing, and its applications in major heavy industries and light industries are also becoming popular. Laser cutting accounts for more than 40% of industrial laser processing and is the most important application technology in the laser processing industry.

Laser cutting is used in the construction machinery industry. Before 2010, due to the high price of laser cutting equipment, a large-format laser cutting machine (equipped with a 4 kW laser) sold for nearly RMB 6 million. Domestic companies using large-format laser cutting machines Not much.

From 2003 to 2009, under the continuous promotion of industrial processing requirements, domestic companies actively introduced laser cutting equipment. For example, Hefei Hitachi introduced 5 large covering laser cutting machines and 2 small covering laser cutting machines. It is planned to introduce 27 sets of large-surface laser cutting machines during the year. Through the introduction in 2008 and 2009, 15 sets of laser cutting machines have been installed in Kunshan Heavy Machinery, Shenyang Sany and other enterprises. Companies such as XCMG and Shantui have successively cited laser cutting machines unwilling to lag behind. In mid-2009, JPSA, a laser micromachining system manufacturer, plans to double the area of its manufacturing workshop and increase the company's production capacity for laser micromachining (laser engraving) systems to meet the needs of manufacturers that produce solar panels (including kilowatts).

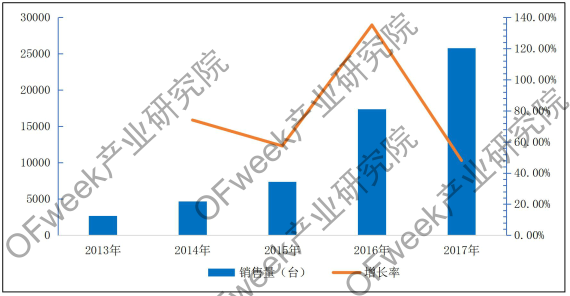

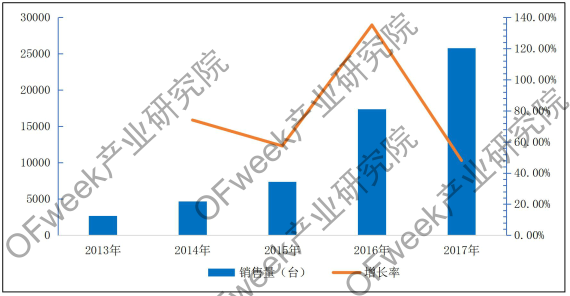

Since 2011, domestic laser companies have vigorously developed high-power fiber laser cutting machines. Due to the unique processing advantages of high-power fiber laser processing, processing costs have dropped significantly. At the same time, combined with a variety of flexible payment methods, more and more sheet metal Processing companies, kitchen and bathroom manufacturing companies, and auto parts processing companies are increasingly using laser cutting machines. In recent years, laser processing equipment has been rapidly popularized. In 2017, the sales volume of laser cutting equipment in my country exceeded 25,000 units.

Chart 2: 2013-2017 China's laser cutting equipment sales volume

Source: OFweek Industry Research Institute

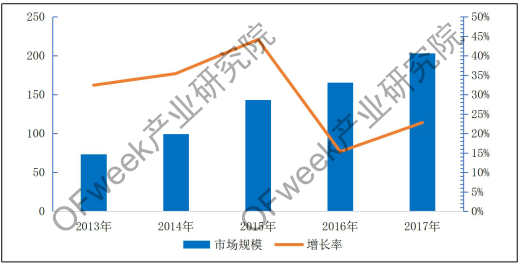

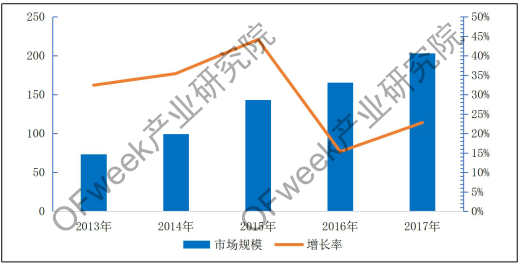

In 2017, the global laser processing equipment market was worth US$31.37 billion, a year-on-year increase of 12%. In 2017, the total sales scale of China's laser equipment market exceeded 44.2 billion yuan, of which laser cutting equipment accounted for 46% of the national industrial laser processing equipment market.

Chart 3: 20103-2017 China's laser cutting equipment market scale (unit: 100 million yuan)

Source: OFweek Industry Research Institute

In 2017, the market size of China's laser cutting equipment was 20.3 billion yuan, with a growth rate of 23%. Among them, the sales scale of small and medium-power laser cutting equipment has maintained a high growth rate, and its core lasers have achieved a high localization rate. Compared with low- and medium-power laser cutting machines, high-power laser cutting machines have developed relatively late and are more dependent on foreign imports. The price of imported high-power lasers remains high, equipment prices are still very high, and the market growth rate is relatively low.

In recent years, domestic laser cutting machine technology has made breakthrough development, and is advancing in the direction of high power, high precision and large format. Under the background of China's intelligent manufacturing, the industrial field is showing a trend of transition from traditional processing to high-end manufacturing. The market scale of China's laser cutting field will always maintain a trend of rapid development.