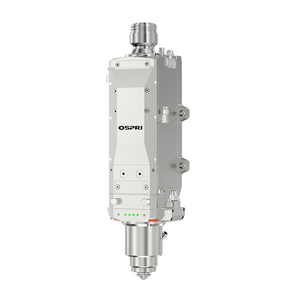

8000w laser chiller

Matching 8000W fiber laser-large cooling capacity, stable performance and trouble-free, clean water quality, good heat exchange effect with fiber laser, and linkage signal to protect the laser...

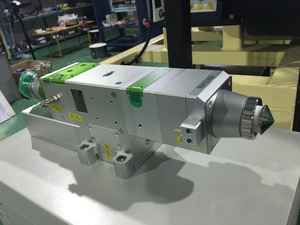

Laser chillers are often used to cool UV lasers, CO2 laser glass tubes, semiconductor lasers, CO2 radio frequency tube lasers, fiber lasers in cutting machines, marking machines, engraving machines, and other equipment. The user can choose the applicable chiller according to the different power of the laser.

product description

Installation instructions edit Voice

The installation and use of the laser chiller is very simple. The first use of the new machine can be carried out according to the following steps:

1. Open the package and check whether the machine is in good condition and whether the accessories are complete.

2. Unscrew the water injection port of the machine and add cooling water.

When adding water, observe the water level of the water level gauge and add water slowly, being careful not to let the water overflow! Appropriate amount of anti-corrosion agent should be added when cooling equipment made of carbon steel. Non-corrosive antifreeze should be added to the cold areas in the north.

3. Connect the outlet pipe and inlet pipe according to the equipment.

4. Plug in the power cord and turn on the power switch. (It is strictly forbidden to start without water!)

(1) After turning on the power switch, the circulating pump of the chiller starts to work. When the new machine is turned on for the first time, there will be more air bubbles in the pipeline, which will cause the machine to alarm occasionally, and it will return to normal after a few minutes of operation.

(2) After starting the machine for the first time, check the water pipes for leaks immediately.

(3) After turning on the power, if the water temperature is lower than the set temperature, it is normal that the fan and other devices of the machine do not work. The thermostat will automatically control the working status of compressors, solenoid valves, fans and other components according to the set control parameters.

(4) Since compressors and other components have a long start-up process, ranging from tens of seconds to several minutes according to different working conditions, do not switch the machine frequently.

5. Check the water level of the water tank.

After the new machine is turned on, the air in the water pipe is emptied, and the water level of the water tank will drop slightly. In order to keep the water level in the green area, you can add water again. Observe and record the current water level. After the chiller has been running for a period of time, observe the water level gauge again. If the water level drops significantly, check the leakage of the water pipes again.

6. Adjust the parameters of the thermostat.

The intelligent thermostat used in the 5300 chiller generally does not need to adjust the control parameters. If necessary, please refer to "Operational Status and Parameter Adjustment" on page 18.

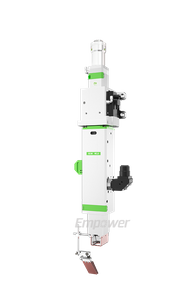

Parts introduction

The parts of the laser chiller include: water pressure gauge, temperature controller, flow alarm indicator (red), normal flow indicator (green), air inlet (filter), power switch, water inlet, drain, etc.