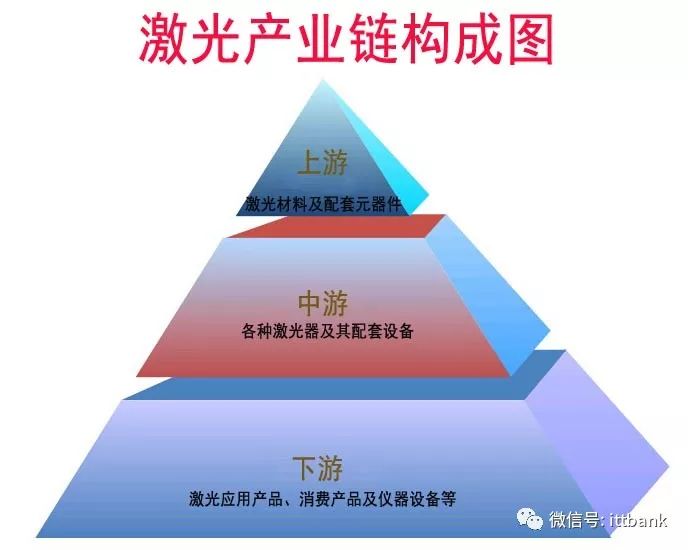

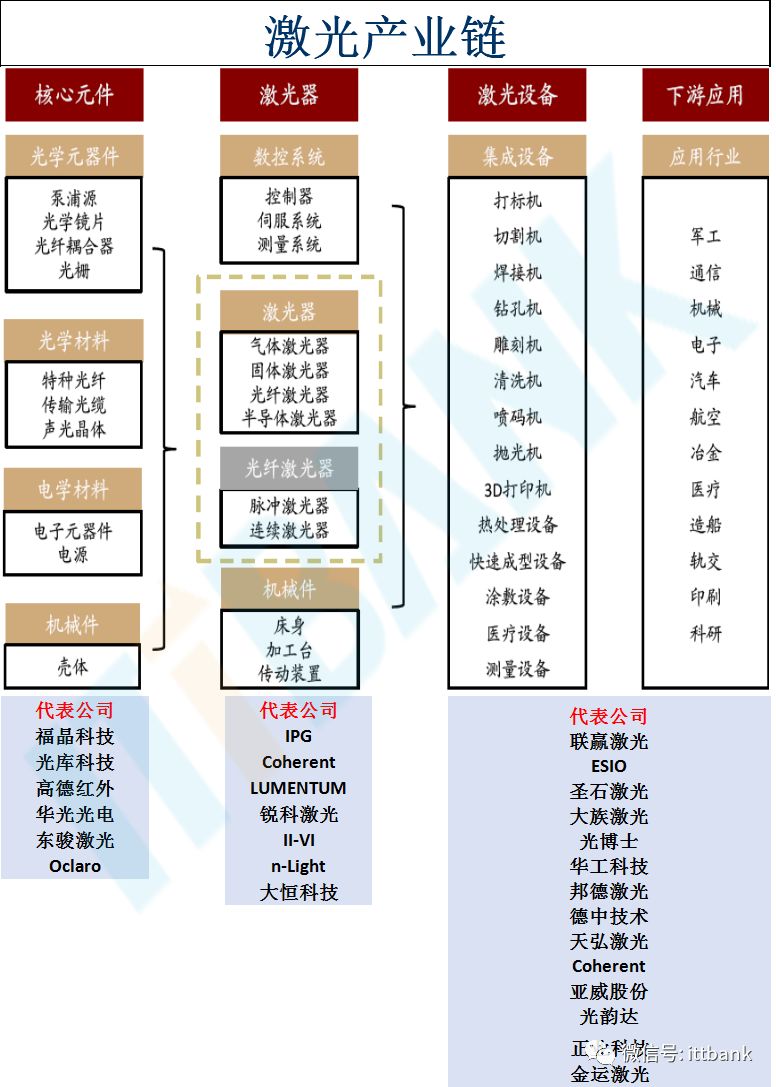

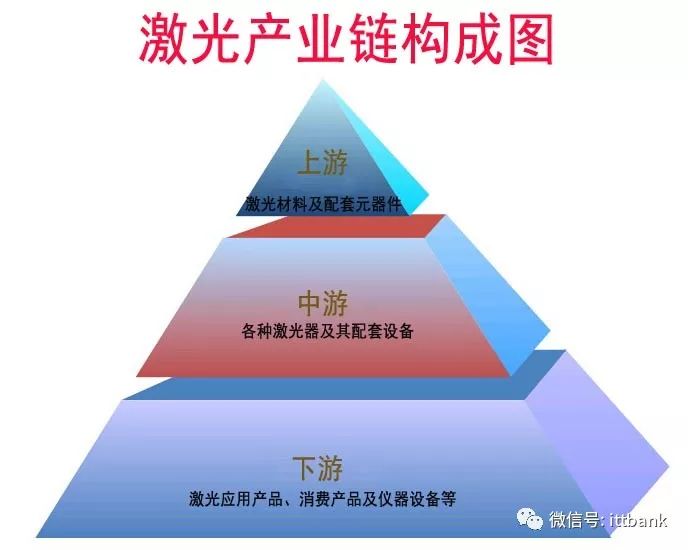

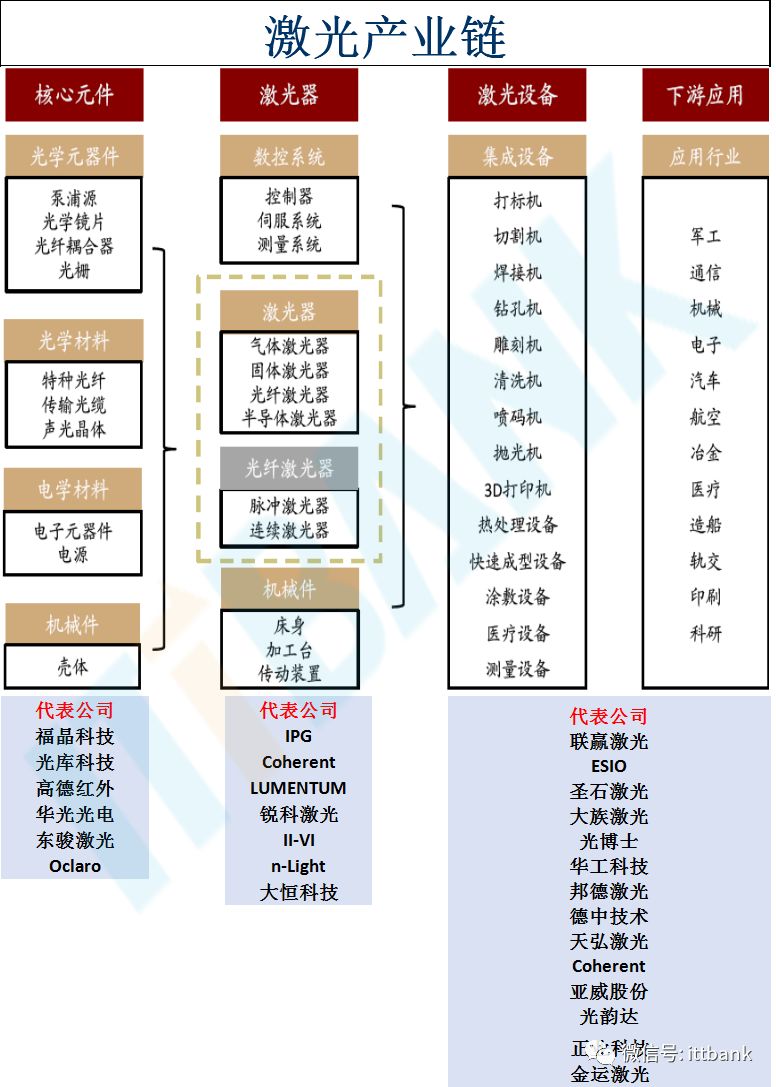

Upstream of industry: small proportion and large space

The upstream of the industry is mainly laser materials and supporting components.

Mainly include: laser crystal, laser gas, laser lamp, laser power supply, laser processing coating, laser components, laser supporting software, etc.

Representative companies include: Fortune Technology, Optical Library Technology, AutoNavi Infrared, Huaguang Optoelectronics, Dongjun Laser, Oclaro, etc.

Midstream Industry: Difficulties in Tackling Key Problems and High Profits

The middle reaches of the industry are mainly various lasers and their supporting equipment.

Mainly include: solid-state lasers, semiconductor lasers, fiber lasers, gas lasers, liquid lasers, other lasers, laser diodes, numerical control equipment, computers, equipment and packaging, electromechanical products, instrumentation, laser modules, etc.

Representative companies are: IPG, Coherent, LUMENTUM, Raycus Laser, II-VI, n-Light, Daheng Technology, etc.

Downstream of the industry: technology applications co-exist with the largest number of companies

The downstream industries are the closest to life, mainly for laser application products, consumer products and equipment.

Mainly include: laser processing, optical communication, optical storage, laser medical treatment, laser marking, laser phototypesetting and printing, laser measurement, laser display, and laser weapons. The number of enterprises located in the downstream of the industry is the largest.

Representative companies are: United Win Laser, ESIO, Sacred Laser, Han's Laser, Doctor of Light, Huagong Technology, Bond Laser, German-Chinese Technology, Tianhong Laser, Coherent, Yawei shares, Sunshine Technology, Zhengye Technology, Jinyun Laser Wait.

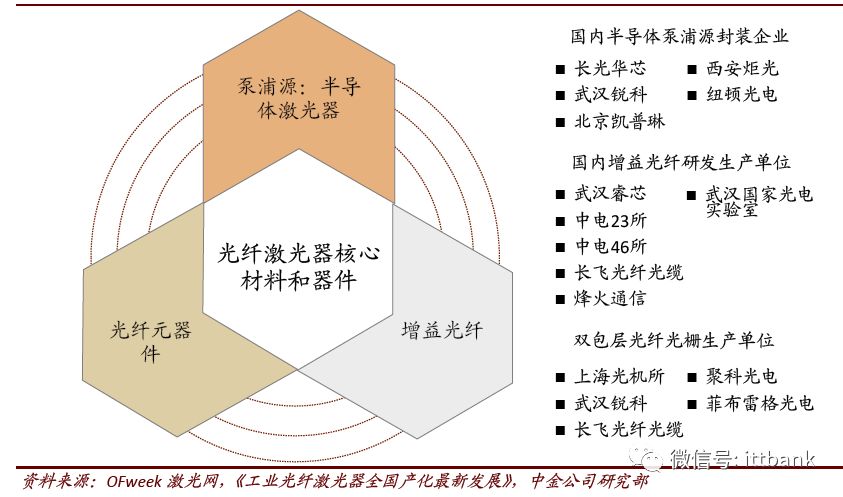

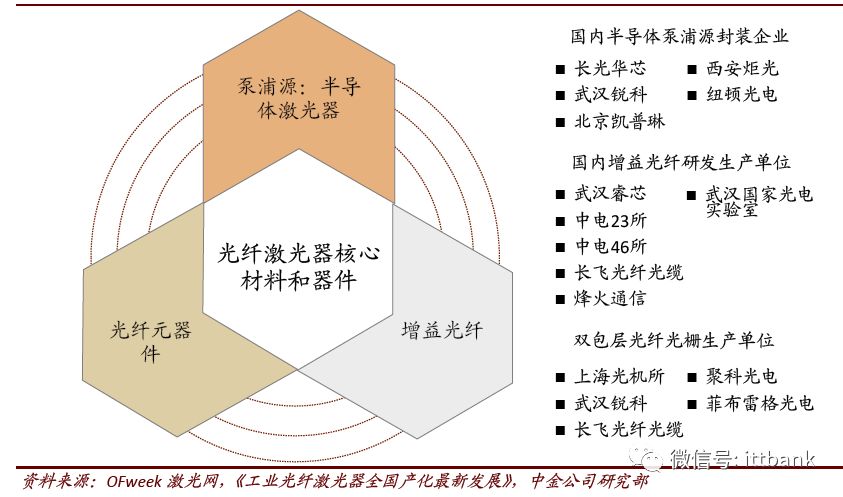

Fiber laser upstream core component manufacturer

China's laser industry is geographically highly agglomerated. At present, four major laser industry belts have been formed in Central China, the Pearl River Delta, the Yangtze River Delta, and the Bohai Rim.

Wuhan Optics Valley is a large-scale optoelectronic industry cluster center in China. It has gathered more than 200 well-known domestic laser companies, including China Engineering Technology, Raycus Laser, Jinyun Laser, AutoNavi Infrared and other well-known laser companies. Wuhan Optics Valley is a veritable Laser Valley of China. It has a complete laser industry chain and gathers many experts and technical talents in the domestic laser field. Wuhan Optics Valley has a professional and large-scale national-level base for production, education and research, which occupies the domestic market in laser-related technologies. leading position.

The Pearl River Delta region is another major agglomeration center of China's laser industry. Related industries are mainly distributed in the major cities of Shenzhen, Guangzhou, Dongguan, and Foshan. The center of the Pearl River Delta laser industry cluster is Shenzhen. Shenzhen has many well-known companies in the industry, such as Han's Laser, Sunshine Laser, United Win Laser, Chuangxin Laser, and JPT Optoelectronics, covering a wide range of laser applications. In terms of market-oriented operation, Shenzhen has an unmatched advantage in Central China. In 2014, Shenzhen’s laser industry output value surpassed Wuhan and became the first city in laser industry output value. The laser industry exports in the Pearl River Delta accounted for the country’s laser product exports. More than 30%.

The Yangtze River Delta region is one of the main clusters of my country's laser industry. The laser industry chain has been completed. The Yangtze River Delta laser industry is mainly distributed in Shanghai, Nanjing, Wenzhou, Suzhou, Ningbo and other places, with many laser components, lasers and laser application equipment manufacturing factory.

The Bohai Rim region is another important area of laser industry formed after Central China and the Pearl River Delta. The laser industry technology research and development strength in the Bohai Rim region is strong. The market represented by Beijing has gathered a large number of IT and communications industry-related companies, and there is a strong demand for laser products. The booming market demand has driven the development of the laser industry in this region. Generally speaking, laser companies in the Bohai Rim area are mainly concentrated in cities such as Beijing, Tianjin, Shenyang, and Dalian.

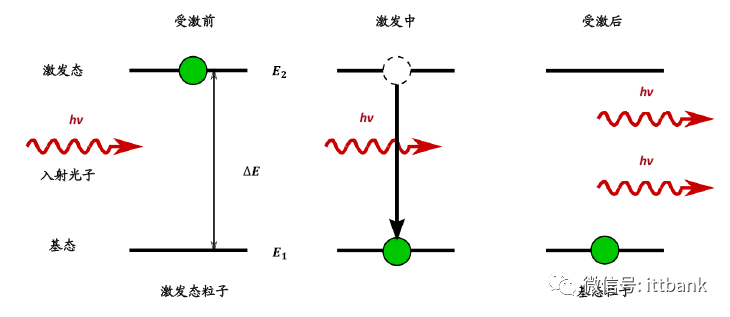

1. Laser principle

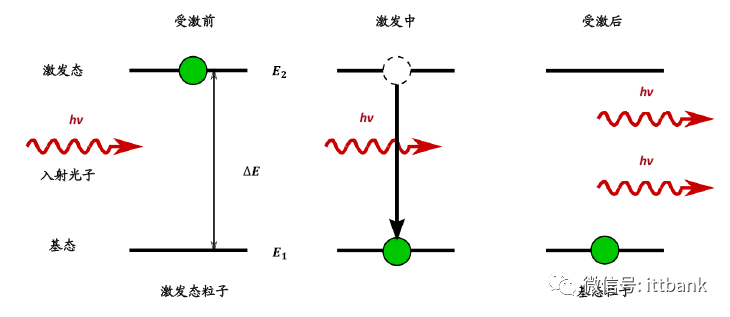

Schematic diagram of stimulated emission (Source: Wiki, CICC Research Department)

The laser light is produced by the excitation radiation process. LASER is the abbreviation of "Light Amplification by Stimulated Emission of Radiation". Stimulated emission was proposed by Einstein in 1917. Dirac first experiment proved the existence of stimulated emission in 1927. In addition to stimulated emission, another light emission process is spontaneous emission.

The core of the principle of stimulated emission is population inversion and energy level transition. The particles at low energy level E1 (working particles can be molecules, atoms, electrons, ions, and excimers) are irradiated by excited photons to transition to high energy level E2. When enough particles are excited, the number of particles will be reduced. Reversal (the number of particles at high energy levels is greater than that of electrons at low energy levels), after which it transitions to the low energy level E1 and radiates a photon with energy E2-E1 (=hv) and exactly the same as the excited photon.

The most important difference between stimulated emission and spontaneous emission is interference. Spontaneous emission is the spontaneous process of particles without external radiation field. The propagation direction and polarization state of spontaneous emission photons are randomly distributed, while stimulated emission is the luminescence process under the control of external radiation field. The frequency, phase, direction of propagation and polarization state are exactly the same as the external radiation field. This is also the essential reason why the laser has the same direction, extremely high brightness, and concentrated energy.

2. The working principle and structure of the laser

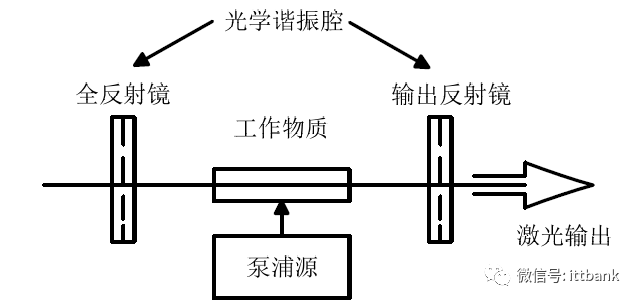

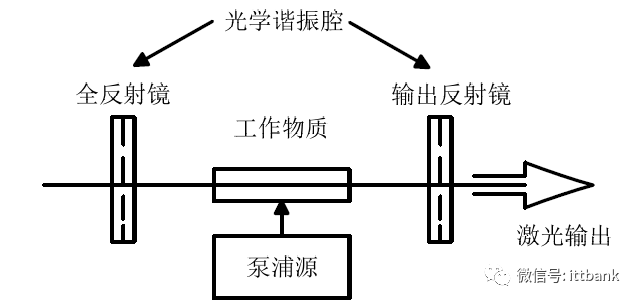

Schematic diagram of laser optics principle

The laser is a laser generating device and has three major functional components: pump source, gain medium, and resonant cavity. The pump source provides the light source for the laser, the gain medium (also known as the working substance) absorbs the energy provided by the pump source and amplifies the light. The resonant cavity is the loop between the pump light source and the gain medium, and the resonant cavity oscillates and selects the mode to output the laser. .

► As an energy source, the pump source is used to generate photons to excite the gain medium. The photons emitted by the pump source pump the particles in the gain medium from the ground state to a high energy level to achieve population inversion. Excitation mechanisms include optical excitation (optical pumping), gas discharge excitation, chemical excitation, and nuclear energy excitation. At present, high-power semiconductor lasers (LD) are generally used as pumping sources, whose main function is to complete the conversion of electrical energy into light energy.

► The gain medium is used to achieve population inversion and amplify the light, and at the same time determine the wavelength of the output laser. The gain medium can be liquid, gas and solid. The basic requirement of the gain medium is to generate photons instead of photothermal conversion after being excited, and the particles in the gain medium must be in a relatively isolated state before the transition between energy levels can occur.

► The resonant cavity mainly plays the role of "storing" and "purifying" the laser. The resonant cavity is usually composed of two mirrors, and a coupler can also be used to form various ring resonant cavities. The photons are reflected back and forth between the mirrors, continuously causing stimulated radiation in the gain medium, producing high-intensity laser light. At the same time, the resonant cavity can make the photons in the cavity have the same frequency/wavelength, phase and running direction, so that the laser has good directivity and coherence.

Third, the classification of lasers

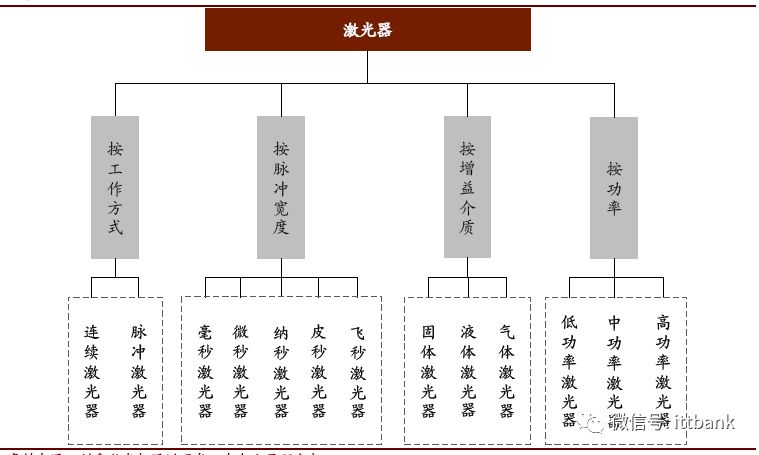

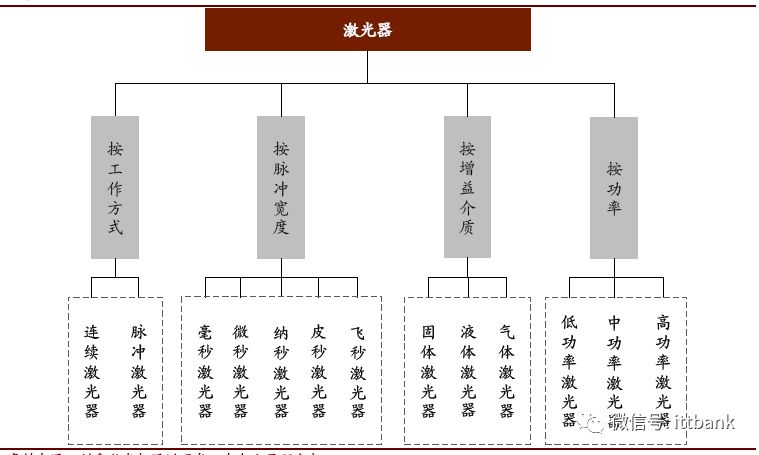

Laser classification

There are four common types of lasers, which are distinguished by gain medium, output power, working mode and pulse width.

► According to the gain medium (working substance): The gain medium of the laser includes gas, liquid and fixed. The specific gain medium determines the laser wavelength, output power and application field. The representative gas is CO2 gas laser, and the representative solid state includes ruby laser, semiconductor laser and fiber laser, YAG laser and so on.

► According to output power: it can be divided into low power (0-100W), medium power (100-1KW), and high power (above 1KW); but sometimes the range of 100-1.5KW is defined as medium power. Different power lasers adapt to different application scenarios.

► According to the working mode: it can be divided into continuous laser and pulsed laser. CW lasers can continuously output for a long period of time, work stably, and have high thermal effects. Pulsed lasers output in the form of pulses. The main characteristics are high peak power and small thermal effects. According to the length of the pulse, pulsed lasers can be further divided into milliseconds, microseconds, nanoseconds, picoseconds and femtoseconds. Generally speaking, the shorter the pulse time , The higher the single pulse energy, the narrower the pulse width, and the higher the processing accuracy.

► According to the output wavelength: it can be divided into infrared laser, visible laser, ultraviolet laser, etc. Materials with different structures can absorb light in different wavelength ranges. For example, metals have a higher absorption rate of near-infrared light.

Core point of view:

From the perspective of gain media, fiber lasers are the main trend;

From the perspective of output power, high power has become the focus of the competition;

From the perspective of working methods, continuous and pulsed have their own magical powers;

From the point of view of laser wavelength, tunability determines the breadth of application.

Four, fiber exciter

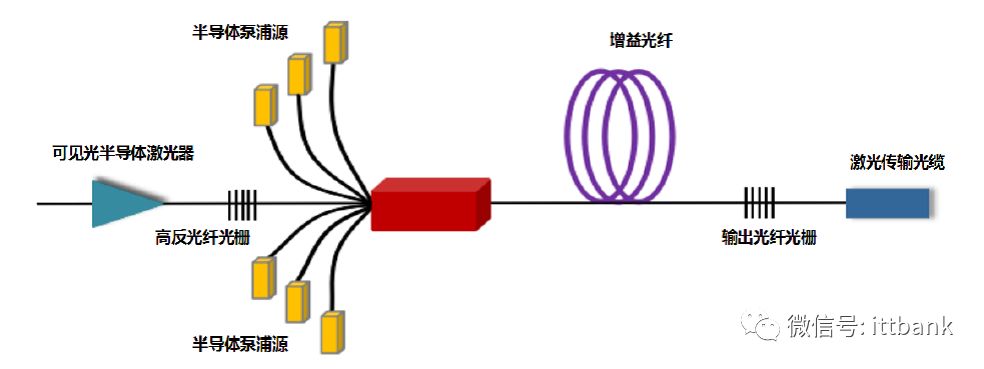

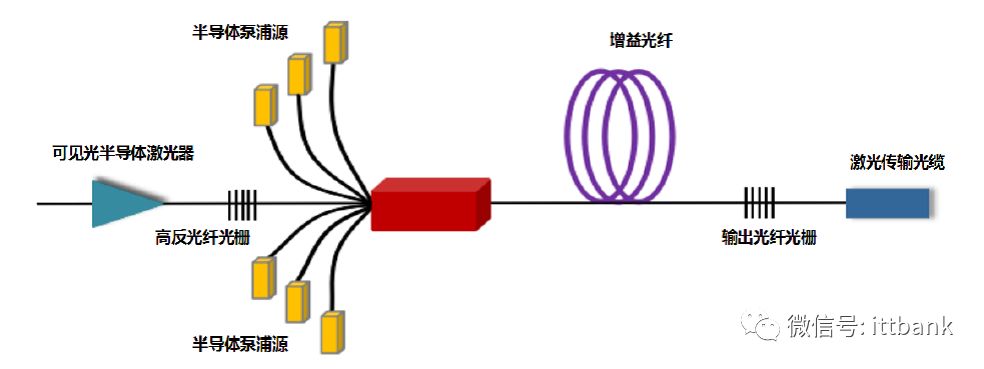

Schematic diagram of fiber laser

Fiber laser refers to a laser that uses glass fiber doped with rare earth elements as a gain medium. Fiber laser generally uses fiber grating as resonant cavity, semiconductor laser as pump source, pump light is coupled into gain fiber from the beam combiner, and is reflected multiple times in the cladding through the doped fiber core, forming population inversion and output laser. The fiber laser can be designed as a whole, with high reliability, good stability, compact structure and low manufacturing cost.

Fiber lasers are often divided into pulsed and continuous fiber lasers. The overall growth rate of pulsed lasers is lower than that of medium and high power continuous lasers, and the barriers are lower. There are many domestic participants and the market competition is fierce. At present, the performance of domestic manufacturers' products is almost the same as that of imported products, but the price is about half of that of imported products.

Fiber lasers can also be divided into single-mode and multi-mode. Single-mode fiber lasers use single-mode fiber as the gain medium, and only operate the fundamental mode laser stably. The single-laser energy is concentrated and the divergence angle is small. It has advantages in laser processing that requires high energy density, but the single-mode laser power is generally below 2KW . Multi-mode fiber lasers exist in both the fundamental mode and other high-order modes of lasers, so the beam diverges, the spot is larger, and the power is higher, which is more suitable for processing that requires a larger heating area.

5. Domestic key companies in the laser industry

Upstream companies:

Fortune Technology focuses on the R&D and production of optical crystals, precision optical components and laser devices, and is widely used in the midstream of the industry in lasers, optical communications and other industrial fields.

Lithium Triborate Crystal (LBO Crystal) produced by Fortune Technology

AutoNavi Infrared is mainly engaged in detectors and movement modules with infrared thermal imaging technology as the core, which are widely used in mid- and downstream optoelectronic systems and weapon systems.

Optical Library Technology focuses on high-performance optical passive devices, and has applications in important fields such as fiber lasers, fiber communications, aerospace, and sensor detection.

Midstream companies:

Raycus Laser specializes in the R&D and large-scale production of high-power fiber lasers and core components. It is the largest and globally influential fiber laser R&D and production base in China. It is the first to develop the first 10,000-watt fiber laser with independent property rights. , Provide power for the manufacture of downstream laser equipment.

Single-module continuous fiber laser produced by Raycus Laser

Daheng Technology’s main products are optical mechatronics products, information technology and office automation products, a variety of precision optical and mechanical standard parts products, ultra-fast lasers and application system products, including high-precision products for teaching, scientific research, and satellite surveys. Distance, industrial precision processing, terahertz spectrometer, picosecond and femtosecond lasers for grating etching, as well as optical components and instruments used in medical treatment.

Downstream companies:

Han's laser has the largest volume and wide coverage. It has formed laser technology as the core, radiation laser, intelligent equipment, applied electronics, semiconductor and display panel, new energy lithium battery, robot, LED, home appliance hardware, automobile and other industries, covering the industry In the middle and lower reaches, it has a leading position in the domestic laser industry.

Zhengye Technology mainly applies laser technology in LCD modules, new energy, PCB, welding and other industries, and high-end equipment and automated production lines are the main force of performance growth.

Yawei started as a metal forming machine tool. With its forward-looking layout of laser and intelligent manufacturing, it has built a "troika" for its own development, and its laser processing equipment has been highly praised in the market.

Based on the research of precision laser application technology, Sunshine is committed to using "precision laser technology" + "intelligent technology" to replace and break through the traditional production methods to achieve high integration, miniaturization and individualization of products. Mainly engaged in additive manufacturing (laser 3D printing), laser three-dimensional circuit (3D-LDS), flexible circuit board laser forming, precision laser application and other products, to promote the development of the industry in the direction of refinement and precision, and increase the added value of customer products.

In the laser field, Jinyun Laser is based on the manufacture of intelligent laser equipment, helping traditional industrial production systems to be digitalized and flexibly upgraded. At the same time, it also covers 3D printing, AR/VR, 3D interactive display, big data, cloud computing, artificial intelligence, etc. Digital field.

Six, summary

Although the domestic laser industry already has a certain scale, its market share is also growing. Central China, South China, and East China have all formed a complete laser industry chain and reached a certain scale. However, we should also be soberly aware that compared with leading foreign laser companies, domestic laser companies still have some gaps. In terms of laser technology and applications, many key technologies and core components are dependent on foreign manufacturers. It is this This aspect restricts the further development of domestic manufacturers. Especially for high-power lasers, it is still difficult to obtain an equal position with foreign companies, and there are deficiencies in some aspects of market competitiveness. However, due to the positive development of the domestic laser market and the continuous improvement of manufacturers' research and development capabilities, domestic competitiveness is catching up. I believe that in the near future, the domestic laser industry will surely overcome obstacles and gain greater market share.