product description:

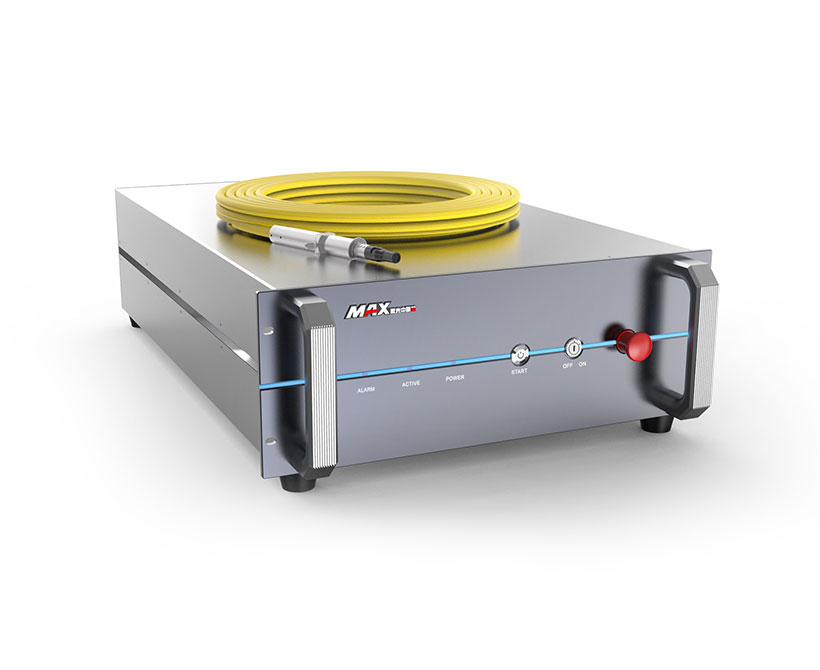

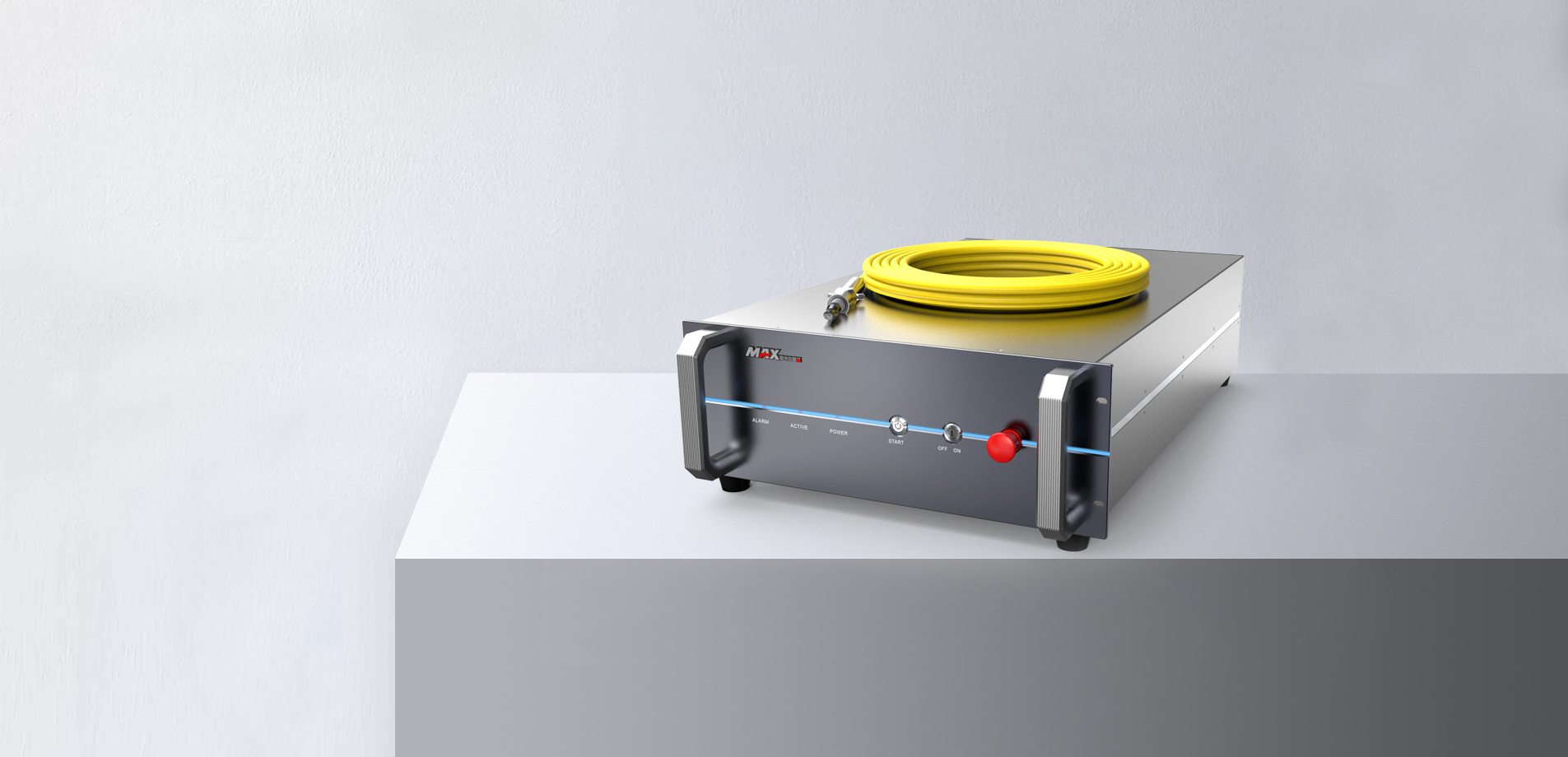

MAX 1000W-2500W dual-wavelength direct semiconductor laser

Product Description:

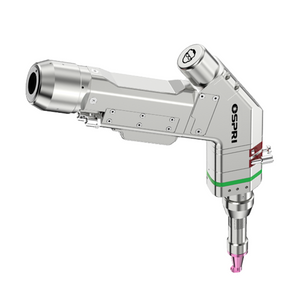

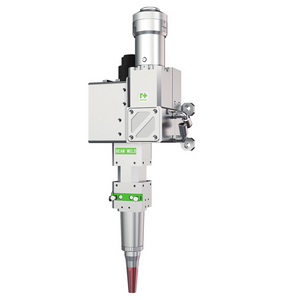

Chuangxin Laser 1000W-2500W dual-wavelength direct semiconductor laser has the characteristics of light weight, small size, high efficiency, long life, high reliability, simple maintenance, and high metal absorption rate. This series of direct semiconductor lasers use modular pump source fiber to combine output. Compared with other company's products, the volume is reduced by 500%+, which is more portable and flexible; the laser output power density is increased by more than 50%, and the beam spot distribution presents a perfect flat top distribution. The energy distribution is uniform and there is no peak; it can be efficiently used in laser brazing, laser tailor welding, large-format high-speed laser cladding, laser surface heat treatment, laser additive manufacturing, laser rapid repair and other fields.

Higher laser utilization

Short wavelength, high absorption rate of metal to laser

High electro-optical conversion efficiency

The light conversion efficiency of the whole machine is more than 45%, energy saving and environmental protection

Output fiber core diameter is smaller

The fiber core diameter is smaller, the energy density is high, and the thicker material is welded

Dual-wavelength laser output, flat-top beam output

The spot energy is evenly distributed, and the processing effect is better, which can meet more processing applications

Wider application range and better effect

At the same time, it can meet welding, cladding and surface heat treatment

Mode switchable

Can switch between pulse and continuous mode, and simultaneously handle the processing tasks of two different lasers in the past

Industry application:

Sheet metal processing

Cutting and welding of steel plates and steel pipes

Rail

Track corrosion laser cleaning, track parts cutting, track joint welding

aerospace

3D printed metal parts inside the aircraft, laser cleaning and refurbishment of aircraft engines/fuselages

PV

Sample Show:

Inner Hole Cladding

| Models | MD-1000W | MD-1500W | MD-2000W | MD-2500W |

| OPTICAL SPECIFICATIONS |

| Nominal Power | 1000W | 1500W | 2000W | 2500W |

| Mode of Operation | CW/Modulated |

| Polarization | Random |

| Power Tunability | 10 to 100% |

| Wavelength | 920 ± 10 nm

975 ± 10 nm |

| Power Stability | ±1 % |

| Laser Beam Quality, BPP | 20~22 mm*mrad(200μm)

25~28 mm*mrad(300μm)

30~33 mm*mrad(400μm) |

| Modulation Frequency | ≤20 KHz |

| Preview red light power | 150 μW |

| FIBER DELIVERY SYSTEM |

| Interface | QBH |

| Length | 15m standard, other lengths optional |

| Diameter | 200 μm | 300 μm | 400 μm |

| Bending Radius | 200 mm |

| ELECTRICAL RATINGS |

| Supply Voltage | 380 VAC |

| OTHER SPECIFICATIONS |

| Operating Temperature | +10 to +40℃ |

| Storage temperature | -10 to +60℃ |

| Humidity | 10 to 85% |

| Cooling Method | Water Cooling |

| Cooling Medium | Distilled water/ Glycol Antifreeze |

| Dimension | 800×482.6×192 mm |

| Weight | 58(±3) kg

|