Laser lens wiping steps:

1. Wash hands, blow dry or dry

2, put on the finger cot

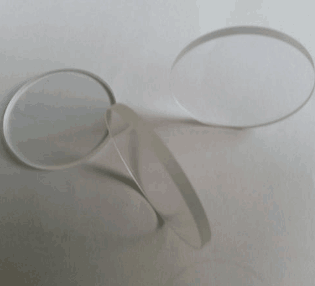

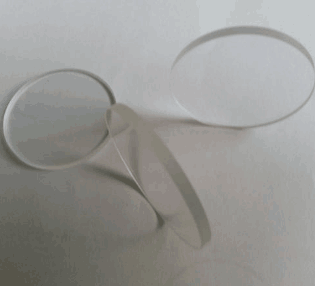

3, gently remove the lens inspection

4. First blow off the dust on the lens surface with air balls or nitrogen.

5, stick the residue with the cotton ball dipped in the mirror liquid

6. Gently wipe the appropriate amount of the mirror with a mirror of the lens, and avoid rubbing it in a rotating manner.

7. Replace the lens paper and repeat step 6. Do not reuse the same lens paper.

8, blow the mirror clean with an air ball

Laser lens maintenance taboo:

1. Do not touch the mirror with your hand.

2. Do not spray on the mirror or use the air of the air compressor.

3. Do not touch the hard surface directly on the mirror surface.

4. Do not wipe with non-mirror paper (stick) or wipe the lens with force

5, do not force the lens when disassembling

Laser lens cleaning method: When cleaning the lens, be very careful. Before cleaning the lens, please see the following precautions:

1. Always wear finger cots or rubber gloves when handling the lens, as dirt and oil droplets on your hands can stain the lens, causing performance degradation.

2. Do not use any tools to take the lens, such as tweezers.

3. Place the lens on the lens paper to avoid damage.

4. Do not place the lens on a rough or hard surface. The infrared lens is easily scratched.

5. Do not clean or touch the surface of pure gold or pure copper.

Cleaning steps:

The first step is to gently clean the light pollutants (dust, floc) and blow off the surface of the lens with an air ball. If the pollutants cannot be blown off, continue to the second step. Note: Do not use the compressed air of the factory because It contains a large amount of water and oil, which forms a harmful absorption film on the surface of the film. (The lens with the lens holder only needs the first step);

Step 2 Gently clean light contaminants (dust, fingerprints). Use acetone or propanol to wet the cotton swab or cotton ball and gently scrub the surface. Take care to avoid scrubbing. It is necessary to traverse the surface as quickly as possible to facilitate evaporation of the liquid without leaving streaks. If this step does not remove the dirt continue the third step.

Step 3 Moderately clean medium contaminants (saliva, oil droplets) Wet cotton swabs or cotton balls with white vinegar, scrub the surface with a small amount of force, and then wipe off the excess white vinegar with a dry cotton swab. Immediately wet the cotton swab or cotton ball with acetone and gently wipe the surface to remove residual acetic acid.