Speaking of automobile laser welding, it can be traced back to the 1980s, when the car body was mainly welded. In the past forty years, today's laser welding production line has appeared on a large scale in the automobile manufacturing industry and has become one of the outstanding achievements of the automobile manufacturing industry.

The automotive industry began to use laser welding technology in Germany. In the 1980s, European car manufacturers such as Audi, Mercedes-Benz, Volkswagen, and Volvo in Sweden took the lead in adopting laser welding of sheet metal welding for roofs, bodies, and side frames. In the 1990s, American General Motors, Ford and Chrysler are racing to introduce laser welding into automobile manufacturing. Although they started late, they have developed rapidly. Subsequently, Italian Fiat used laser welding in the welding and assembly of most steel plate components, and Japan’s Nissan, Honda and Toyota Motor Corporation also used laser welding processes in the manufacture of body panels. Since then, high-strength steel laser welding assembly parts have been Its excellent performance is used more and more in automobile body manufacturing.

The booming automobile market drives the development of laser welding industry

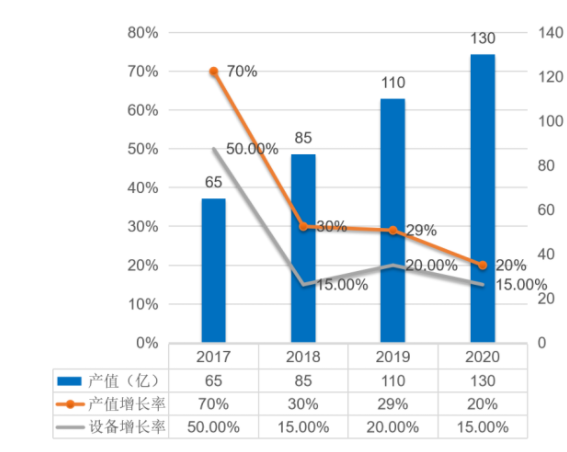

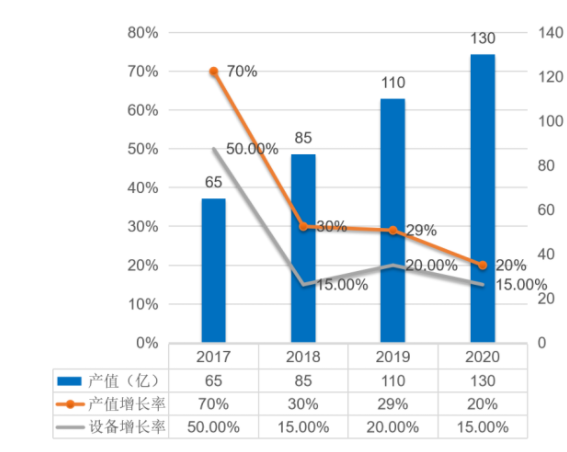

With the transformation and upgrading of my country’s manufacturing industry, the requirements of many industries for the quality of product welding continue to increase. Under this background, the application penetration rate of laser welding in many industries continues to rise, especially the processing and manufacturing of metal materials and parts. The rate is at a relatively high level. At present, the automobile industry is an important application market for laser welding in my country.

The data comes from the statistics of the Laser Processing Committee

Whether it is the "Mid- and Long-term Development Plan for the Automobile Industry" issued earlier or the "Development Plan for the New Energy Automobile Industry (2021-2035)", both have released an important signal: electric vehicles are the established national industrial strategy, and the policy level promotes it. The direction of sustainable and healthy development will not be shaken. These policies are promoting healthy and orderly development from multiple dimensions, and will benefit the development of the new energy automobile industry in the long term.

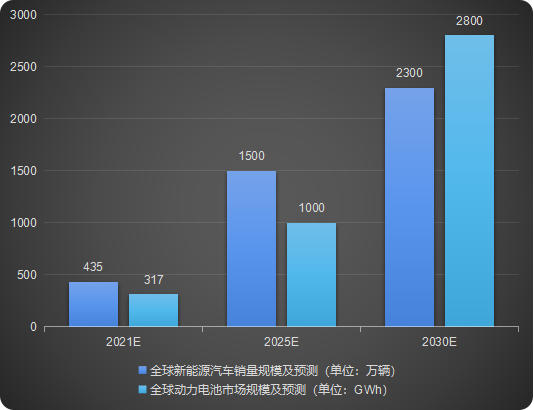

Data source: China Automobile Association

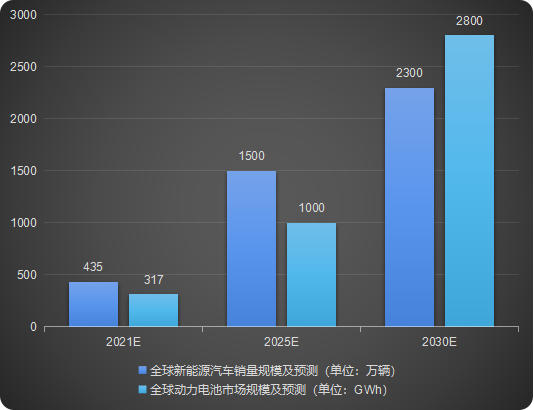

In 2015, my country became the largest country in the sales of new energy vehicles. In the past six years, my country's new energy vehicle sales have maintained a steady upward trend. Following this, the domestic production of new energy vehicles and the lithium battery industry have developed rapidly. According to the statistics of the China Automobile Association, in the first half of 2021, my country's new energy vehicle sales exceeded 1.2 million, and the cumulative power battery installed volume was 52.5GWh. The cumulative sales have been the same as the full-year level of 2019, and the emerging kinetic energy is continuing to expand. Nowadays, the speed of electrification in the global automobile industry is accelerating. Governments of various countries provide policy support such as subsidies for consumers to purchase cars, which stimulates the continuous increase in global sales of new energy vehicles. The Bank of America Global Research Department predicts that the global penetration rate of all electric vehicles, including pure electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs), will rise from 23% to 67% from 2025 to 2040.

Data source: SNE Research, a global emerging energy market research organization

SNE Research, a global research organization for emerging energy markets, predicts that global sales of new energy vehicles are expected to reach 15 million units in 2025, and global sales of electric vehicles will reach 23 million units in 2030. The market capacity is expected to increase by more than ten times. The strong new energy vehicle market will Accelerate the development of the laser welding industry.

Application of laser welding technology in auto parts

A car is assembled from about 20,000 parts, of which iron parts account for the majority. Although collectively referred to as iron, steel plates, transmissions and other boxes are used to form the frame of the car body and the body part of the model. The body part uses a casting made by melting iron and injecting it into a mold. Therefore, the welding process is an indispensable process in the automobile production and processing process, such as frame, body, compartment, engine, automobile gear, roof, door, automobile seat sliding parts, automobile airbag liner, row Steam pipes, automobile clutches, etc. are inseparable from welding technology.

Compared with traditional welding technologies such as traditional resistance welding and carbon dioxide gas shielded welding, laser welding technology is more effective in new alloy materials. It has the advantages of fast welding speed, good quality, high production efficiency, large welding seam aspect ratio, bright and beautiful appearance, small heat input, small welding heat-affected zone, and welding resistance to deformation, etc., making it efficient in the processing of auto parts , Economy, safety, strength, high corrosion and other good performance, can realize the tailor welding, overlap welding, body welding and parts welding of auto parts, effectively reduce body weight, improve body assembly accuracy, increase body strength, and reduce automobile body manufacturing process Stamping and assembly costs. Relying on the exploration in the field of laser welding, Lianying Laser has applied advanced laser flying welding, laser filler wire welding, WOBBLE welding, multi-wavelength blue light composite welding technology and multi-wavelength blue light swing composite welding technology to automobile engine exhaust manifolds and cylinders. Gaskets, high-pressure manifolds, oxygen sensors, gearbox shift forks, half-shell components, steering brackets for automotive steering systems, guide tubes, steering wheel assemblies and many other auto parts are perfectly integrated with modern automobile manufacturing for the future The light-weight development of automobiles provides more high-quality solutions.

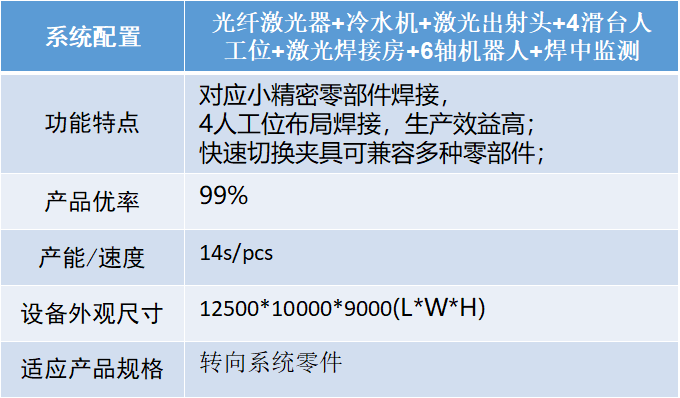

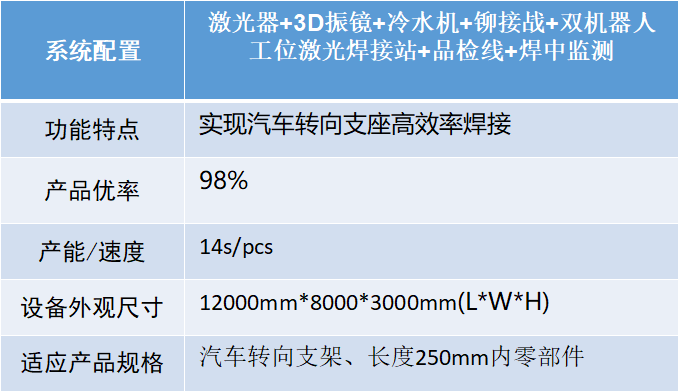

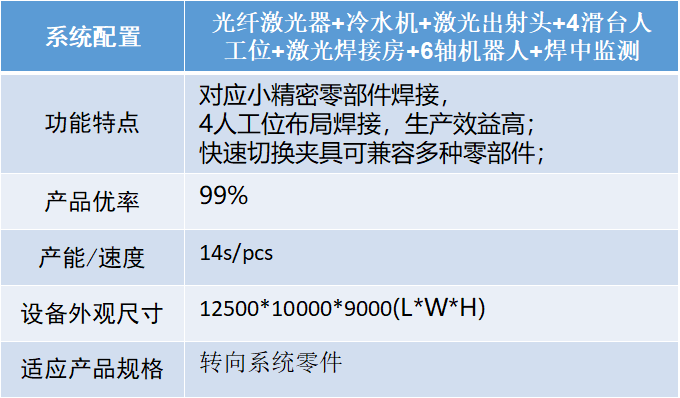

Lianying laser car steering bearing laser welding line

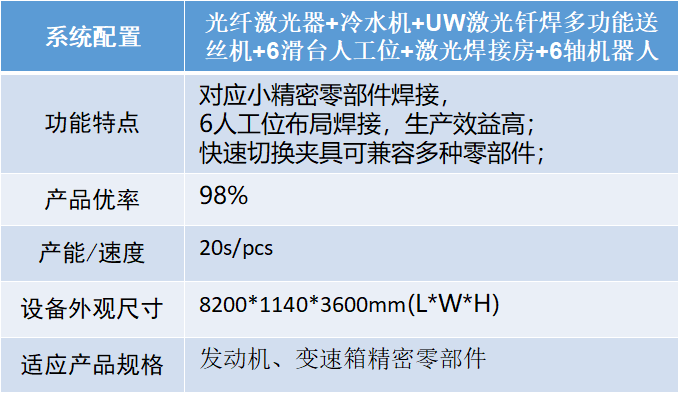

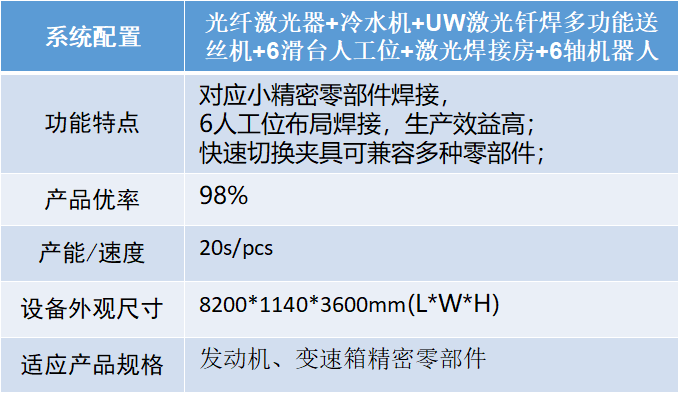

UW Auto Parts Solutions

At present, Lianying Laser has automatic bipolar plate welding lines in the automotive industry, laser brazing workstations for automotive body-in-white roofs, sheet metal unequal thick plate splicing workstations, automotive guide tube bracket laser welding workstations, automotive exhaust manifold welding workstations, and automotive Shift fork + shift shaft laser welding workstation, new energy battery box cover laser cleaning station, fuel distribution pipe welding workstation, steering bearing automated production line, etc. UW hopes to help manufacturers easily realize intelligent manufacturing through rich application case experience and professional technology.

It is suitable for laser welding of automobile parts such as car guide tube mounting brackets.

Difficulties in industrial application: the weld bead of the workpiece is a fillet weld, and the effective penetration depth of the weld bead is required to reach 80% of the plate thickness; there is a large amount of anti-rust oil on the surface of the workpiece, which is not conducive to welding;

Lianying Laser Weapon: When welding, the light output angle is as close as possible to the edge of the workpiece at about 20 degrees; the fixture design ensures the clamping strength to avoid interference with the workpiece and the laser; select the appropriate incident angle, and continuously optimize the laser power and welding speed. Process parameters such as defocus amount; laser cleaning can be selected to remove surface oil and oxides, which is conducive to better welding quality.

Automobile shift fork + shift shaft laser welding workstation

Difficulties in industrial application: There are many parts in the assembly of the product, and it needs to be welded in multiple processes. Greasy welding on the surface of the workpiece is prone to pores.

Lianying Laser Decryption: Choose robots, equipped with multiple sets of automatic welding fixtures; fully enclosed welding protection room, equipped with house dust removal system, to ensure that the manual operation area is safe and pollution-free.

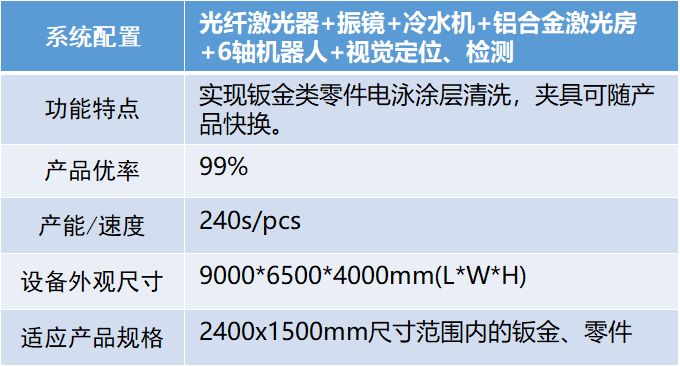

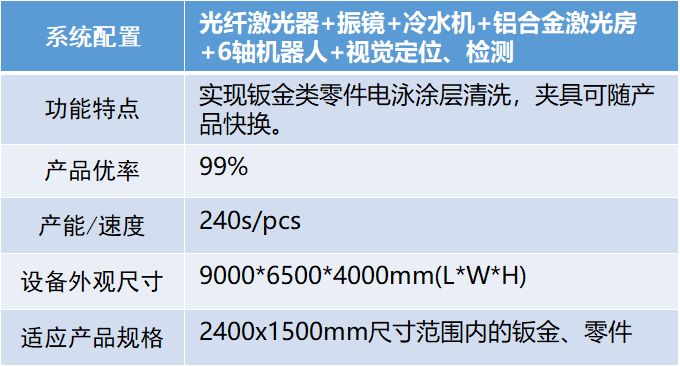

New energy vehicle battery box cover laser cleaning station

This equipment is used for laser cleaning of electrophoretic paint coating on the cover of new energy battery box, corresponding to the paint layer in the range of 10mm in diameter at the edge of 108 circular holes. The thickness of the cleaning coating is guaranteed to be 0.035mm, and the galvanometer matching high-precision robot and laser rangefinder are used to control the cleaning focal length. Achieve 100% excellent rate to ensure the accuracy of cleaning without damaging the galvanized layer under the electrophoretic coating.

Advantages: The special aluminum alloy laser room body is adopted, which is easy to disassemble and maintain, has a beautiful appearance, and is lightweight; the equipment can be placed on the second floor, effectively reducing the floor space; using the shrapnel fixture structure to achieve up to 108 compact positions for independent compression .

Laser welding line for automobile steering bearing

Advantages and characteristics:

The welding station adopts industrial PLC control; integrates automatic marking, oiling, riveting, welding, inspection and other processes to achieve integrated line production; adopts imported fume purifiers to absorb the fumes and splashes generated during the welding process to the purifier Internal filtering to ensure the health of the operators; fully enclosed welding of the room body, observation through the see-through window, all maintenance doors and equipment interlocked (that is, during normal work, the equipment will automatically stop after opening) to ensure the safety of the operators in all aspects; CCD image automatic The monitoring system is convenient for real-time observation of the welding status; the 2-axis positioner is used for real-time displacement, quickly adjusts the angle, and galvanometer welding; the fixture adopts a quick-change device to realize manual loading and fast switching of fixed welding positions to achieve high-speed production beats .

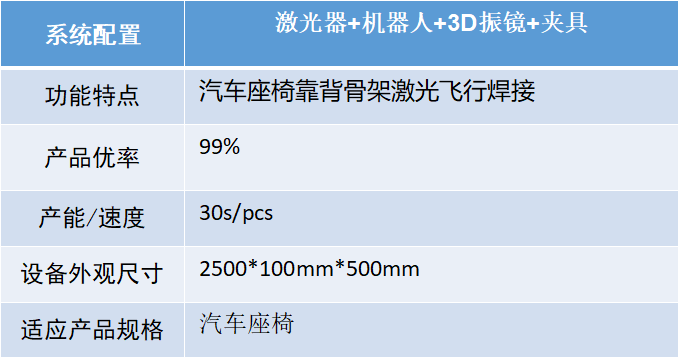

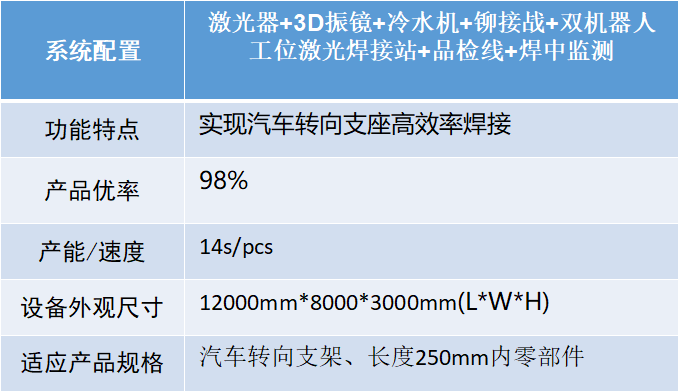

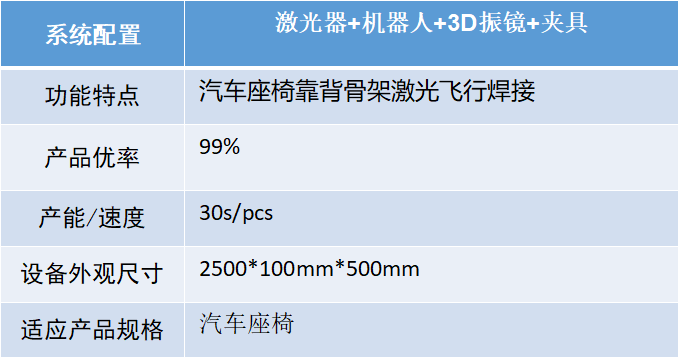

Laser welding of car seat back panel

Difficulties in industrial application: laser flying welding has high efficiency, robots often need to wait for manual loading, and the beat is not high; when the safety level of laser welding is higher, radiation protection is required, and it is difficult to protect the movement edge of the turntable mechanism; laser welding needs to ensure a very small gap , It is difficult to guarantee the gap of the workpiece;

Lianying Laser Decryption: Multi-rotating table stations can be used to reduce the loading and unloading cycle, improve the utilization rate of laser welding, and increase the cycle; Add enough pressure block near the weld to ensure enough pressing force to eliminate the gap between the workpieces;

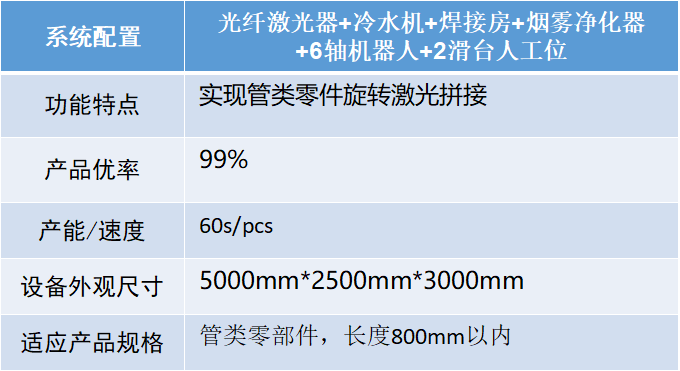

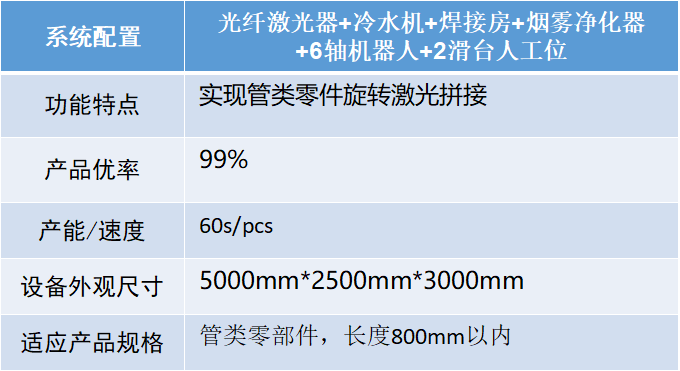

Automobile exhaust manifold welding workstation

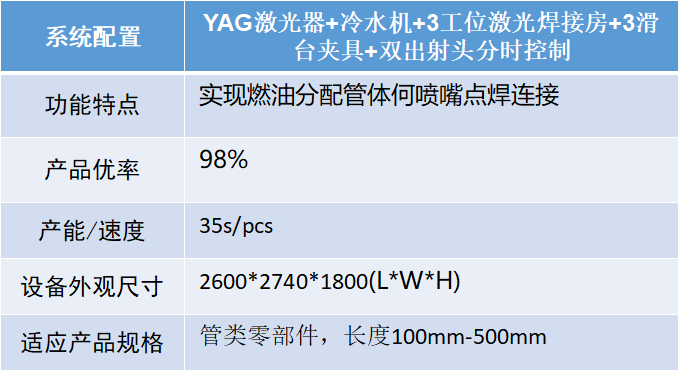

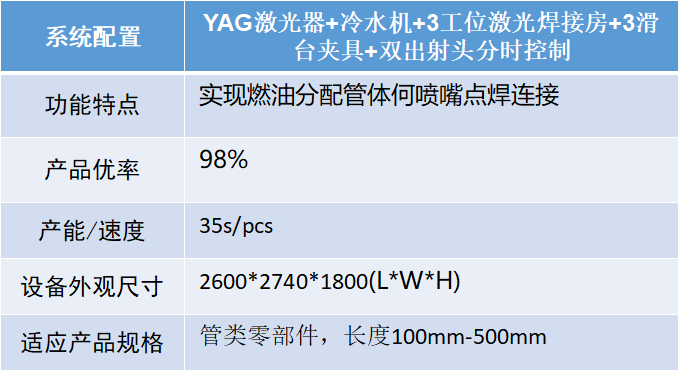

燃油分配管焊接工作站

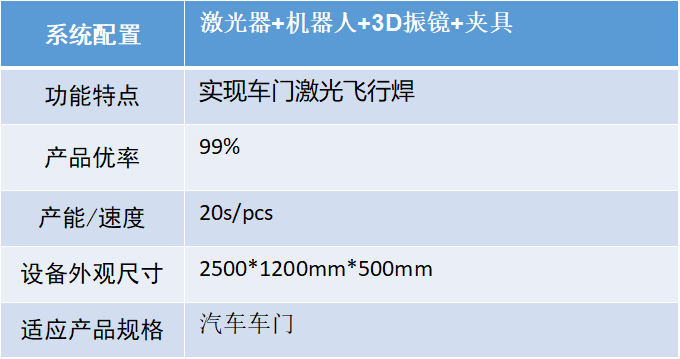

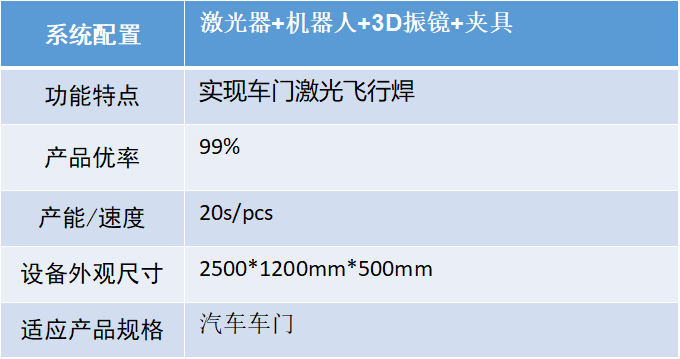

车门激光焊接

Auto parts welding adopts high-power laser welding instead of other welding methods. The deformation of the welding part of the parts is small, the connection accuracy is high, the welding speed is high, the connection strength is high, and no post-weld heat treatment is required. At present, Lianying Laser has established good cooperation with many auto OEMs and auto parts manufacturers. According to the National "Energy-saving and New Energy Vehicle Technology Roadmap", 2025 will reduce the weight by 20% compared with 2015, and in 2030, the weight will be reduced by 35% compared with 2015.

Automobile lightweighting is an inevitable choice for the sustainable and healthy development of my country's automobile industry in the future. Laser welding is a common core technology for energy-saving vehicles and new energy vehicles, and there is a huge market space for lightweighting. In addition, the use of laser welding can also save automobile production costs and improve production efficiency. With the expansion of the global automobile market demand, the combination of advanced laser processing technology and automobile production has become a general trend while the process of automobile intelligence is accelerating. In the future, as the demand for automobiles, especially new energy vehicles, continues to increase, the demand for laser welding in the production line will also continue to increase, and the market space is broad.