1350mm Deburring Machine for Flame Cutting / Oxy-fuel Cutting

With Laser Oxide Removal and Heavy Slag Removal

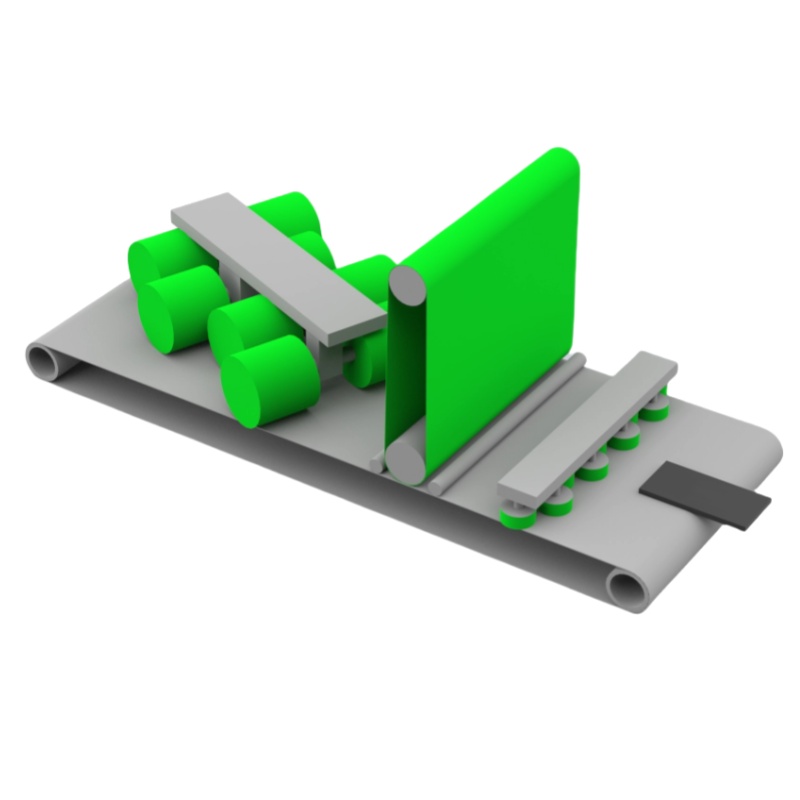

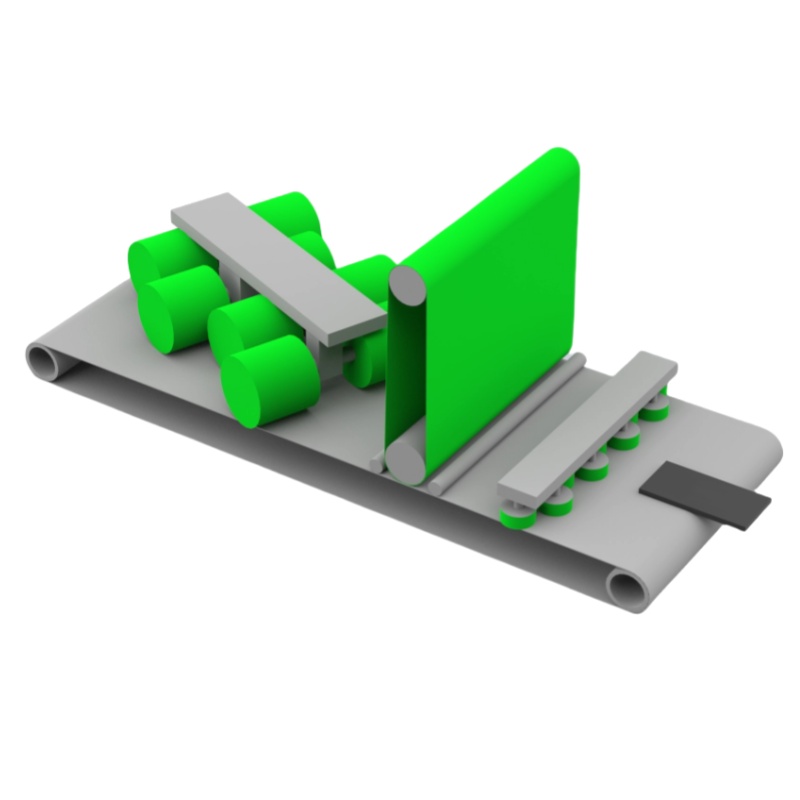

Configuration: Steel Hammer Disc + Sanding Belt + Flap Wheel Brushes

This 1350mm wide heavy-duty deburring and surface treatment machine is specially designed for thick flame-cut and oxy-fuel cut steel plates, as well as laser-cut parts with oxide layers. It features a robust steel hammer deslagging unit, a high-performance abrasive sanding belt, and multi-directional flap wheel brushes, delivering comprehensive post-cut processing in one pass.

Key Features:

Working width: 1350 mm

Processing thickness: 1.5 mm – 100 mm

Minimum part size: 60 × 60 mm

Processing modules:

– Steel hammer disc: Rapid removal of heavy slag from flame/plasma cuts

– Sanding belt: Removal of burrs and laser oxide layers

– Flap wheel brushes: Edge rounding up to R2.0 mm and uniform surface finishing

Material compatibility: Carbon steel, stainless steel, alloy steel, and laser-cut mild steel

Part types supported: Flat sheet metal, structural components, flame-cut profiles

Feed speed: Adjustable from 0.5 – 6 m/min

Control system: Intelligent HMI + PLC with process memory settings

Applications:

Post-processing of flame-cut and oxy-fuel cut parts

Laser oxide layer removal on laser-cut steel plates

Heavy slag removal from plasma and flame cutting

Edge rounding and finishing for safety and coating preparation

Widely used in shipbuilding, steel construction, mining equipment, heavy industry, and welding workshops

✅ Benefits:

Complete solution for slag, burr, oxide removal and edge rounding in a single pass

Reduces manual grinding, rework, and safety hazards

Improves paint and powder coating adhesion

Enhances handling safety and part consistency

High throughput for large and thick workpieces

Modular design — easily customizable or upgradable

Optional Add-ons:

Vacuum or magnetic work-holding table

Dust extraction system (wet or dry)

Automatic thickness adjustment system

Integrated loading/unloading conveyor

Product Overview:

The MSP-DL1350 is a high-performance deburring, slag removal, and edge rounding machine specifically engineered for processing carbon steel sheet metal parts after laser cutting, plasma cutting, flame cutting, punching, or shearing. It integrates a dry steel hammer station, a sanding belt head, and eight multi-directional abrasive disc brush heads, delivering 360° processing for superior surface quality and consistent R-edge rounding.

This machine is a complete dry-processing system that removes heavy slag, laser oxide layers, burrs, and sharp edges in a single pass. It is ideal for applications in heavy fabrication, construction steel processing, machinery manufacturing, and similar industries demanding high throughput and flawless finishing.

⚙️ Key Processing Features:

✅ Heavy Slag Removal — Steel hammer disc brush station removes thick slag after thermal cutting

✅ Laser Oxide Film Removal — Sanding belt station cleans oxidation and residual burrs

✅ Edge Rounding & Deburring — Eight-disc planetary rotary brushes generate uniform R-radius on edges and holes

✅ Independent Stations — Each processing unit can be operated independently for specific needs

✅ Magnetic Conveyor Table — Strong permanent magnetic adsorption ensures part stability without fixtures

✅ Wet Dust Collection System — Efficient water-based dust removal with environmental filtration and safe air exhaust

Applications:

Laser oxide removal

Heavy slag removal (plasma/flame cut parts)

Deburring inner and outer edges

Edge rounding up to R2mm

Surface brushing and polishing

Pre-treatment before painting or welding

Working Principle:

Steel Hammer Station: Oscillating steel hammer discs strike and remove heavy slag and thick burrs.

Sanding Belt Station: Smooths surfaces, removes oxide films, and pre-polishes the material.

Planetary Brush Station: Eight abrasive disc brushes rotate and revolve in opposing directions to deburr and round all edges and inner holes, generating centrifugal action for a uniform R-radius.

All stations are modular and can function independently depending on the processing task.

Technical Specifications:

| Parameter | Specification |

| Max Processing Width | ≤1330 mm |

| Processing Thickness | 0.5 – 80 mm |

| Min Workpiece Size | 50 × 50 mm (solid parts) |

| Total Power | 45.5 kW |

| Abrasive Belt Size | Φ1910 × 1350 mm |

| Brush Disc Size | Φ300 × 400 mm |

| Feed Speed | 0.5 – 6 m/min (VFD adjustable) |

| Sanding Belt Speed | 18 m/s |

| Brush Rotation Speed | 8 – 26 m/s (VFD adjustable) |

| Brush Revolution Speed | 1 – 15 rpm (VFD adjustable) |

| Planetary Brush Heads | 1 planetary set, 8 rotating heads |

| Servo Precision – Thickness | 0.01 mm |

| Servo Precision – Compensation | 0.01 mm |

| Grinding Media | Steel hammer + Sand belt + Brushes |

| Dust Collection Volume | 5000 m³/h |

| Machine Dimensions | L4500 × W2300 × H2500 mm |

| Machine Weight | Approx. 6 Tons |

Main Components & Configuration:

Hammerhead Disc Unit: 9 pcs Φ162mm discs, 11kW motor

Abrasive Belt Grinding Unit: 1pc Φ185mm×1350mm, 15kW motor

Rotary Brush System: 8 rotating heads, 4 × 11kW motors

Servo Motors: For thickness adjustment and brush compensation (VEICHI)

Conveyor System: Magnetic rubber belt, 4kW motor with BKA87 reducer

Control System: VEICHI PLC + 7” Touchscreen HMI

Inverters: VEICHI brand for all motor speed controls

Dust Collection: Water-based wet filtration with high-pressure fan

Electrical Components: CHNT / NSK bearings

Advantages at a Glance:

High Efficiency – Continuous through-feed design supports mass production

Precision Processing – Consistent R-edge rounding and no film damage on coated parts

Cost Reduction – Greatly reduces manual grinding labor and per-unit processing costs

️ Safe & Eco-Friendly – Closed-loop wet dust removal system ensures safe operation and green manufacturing

Flexible Functionality – Each unit operates independently for targeted tasks