Analysis of the advantages of hand-held fiber laser welding machine

Laser welding machine is also often called laser welding machine, energy negative feedback laser welding machine, laser welding machine, laser welding machine, laser cold welding machine, laser argon welding machine, laser welding equipment, etc. Laser welding is a new type of welding method. It is mainly aimed at welding thin-walled materials and precision parts. It can realize spot welding, butt welding, stitch welding, sealed welding, etc., with high aspect ratio, small weld width, and small heat-affected zone. , Small deformation, fast welding speed, smooth and beautiful welding seam, no need or simple processing after welding, high welding seam quality, no air holes, precise control, small focus spot, high positioning accuracy, easy to realize automation.

The laser welding machine is highly automated and the welding process is simple. The non-contact operation method can meet the requirements of cleanliness and environmental protection. Using laser welding machine to process the workpiece can improve work efficiency. The finished workpiece has a beautiful appearance, small weld seam, large welding depth and high welding quality.

So, what are the advantages of hand-held fiber laser welding machine?

Analysis of the advantages of hand-held fiber laser welding machine:

Laser welding machines are widely used in sheet metal processing, rail transit, automobiles, construction machinery, agriculture and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, food machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchenware and bathroom, decorative advertising , Laser external processing services, etc.

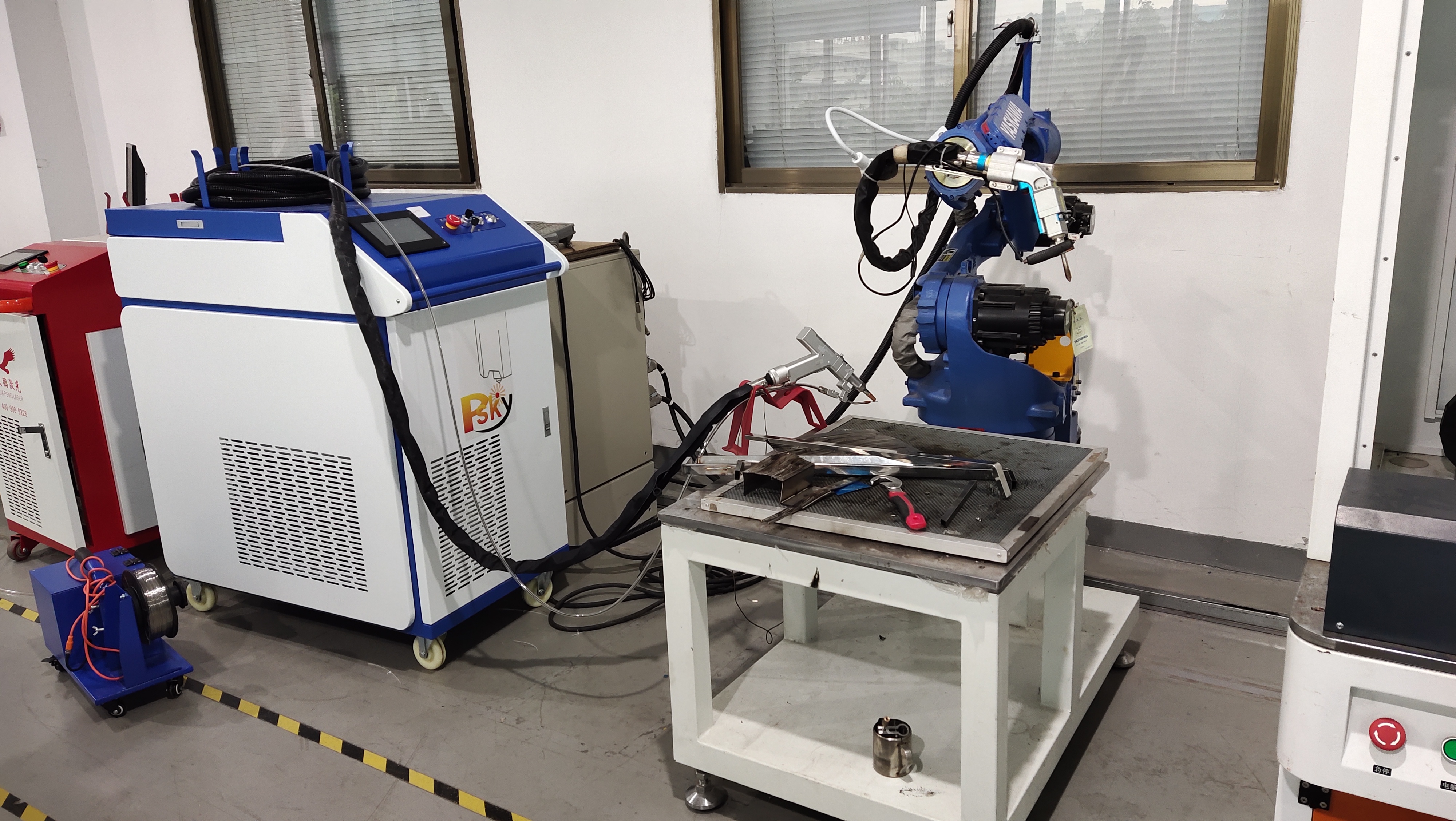

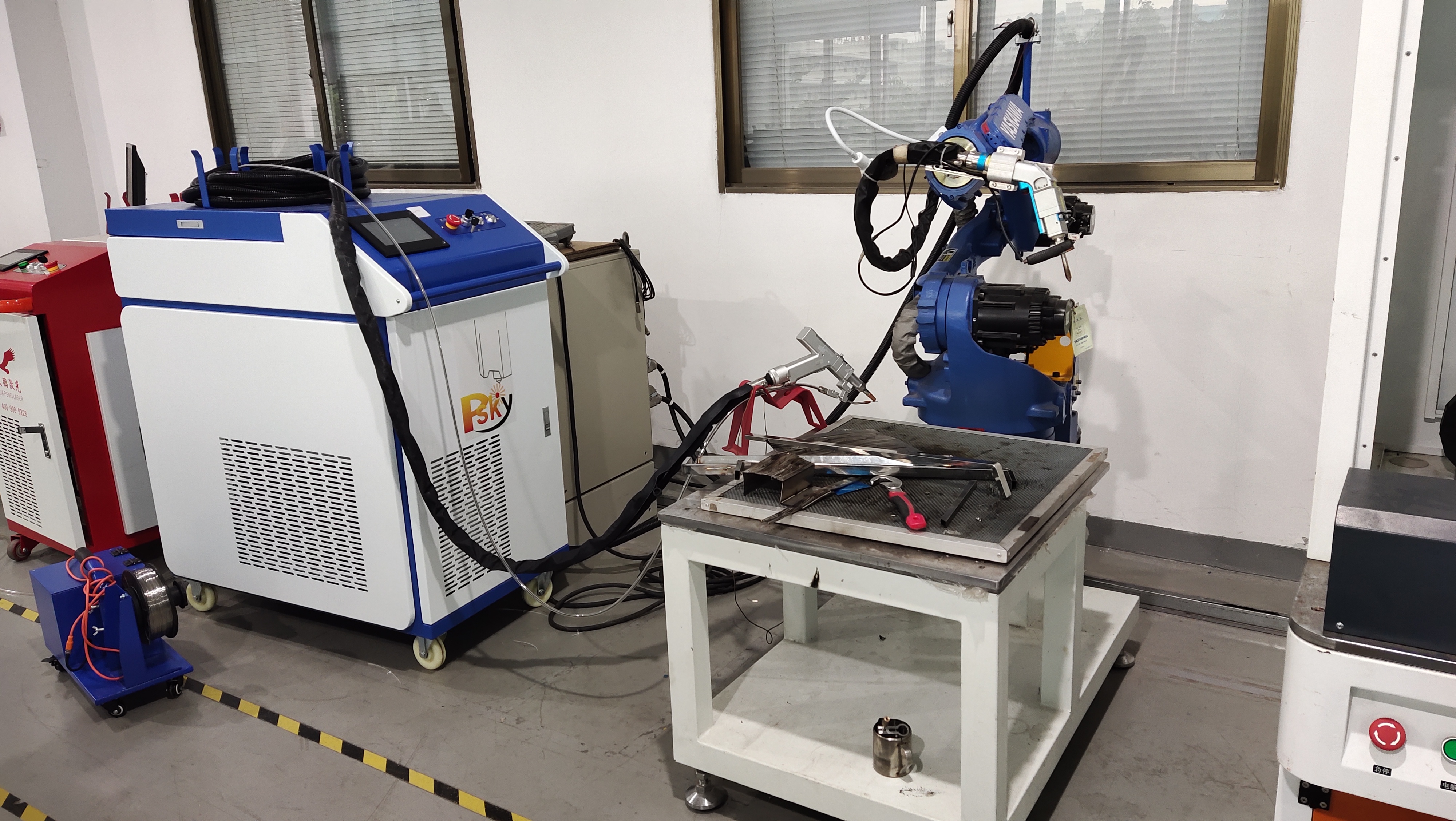

The handheld welding gun replaces the previous fixed light path. The working mode of the hand-held fiber laser welding machine, hand-held welding, flexible and convenient, and the welding distance is longer. The handheld fiber laser welding machine is mainly used for laser welding of long-distance and large workpieces. The heat-affected area is small during welding, and it will not cause work deformation, blackening, and traces on the back. The welding depth is large, the welding is firm, and the melting is sufficient.

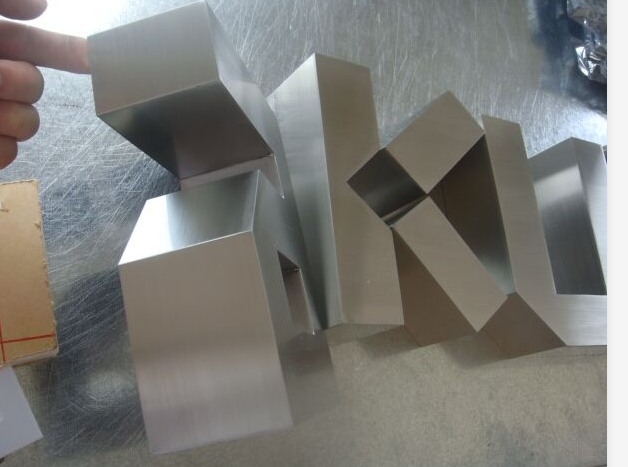

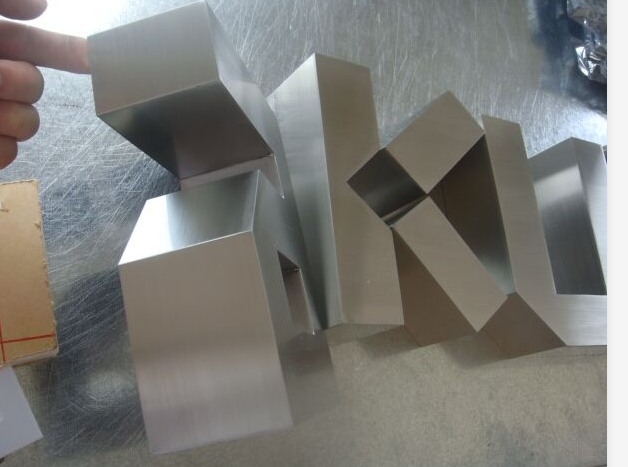

The hand-held fiber optic transmission laser welding machine fills the gap of hand-held welding in the laser equipment industry. The hand-held laser welding machine subverts the working mode of the previous laser welding machine and replaces the previous fixed optical path with a hand-held welding gun. This mode of operation is not only more convenient for the welding of molds, advertising characters, kitchen utensils, doors and windows, etc., but also makes it possible for laser welding to operate outdoors. The handheld laser welding machine is equipped with imported optical fiber, which is flexible and convenient. It can realize outdoor welding. The operation mode of the handheld welding gun can weld the workpiece at any angle. It is suitable for various complex welding seams and spot welding of various devices.

The handheld laser welding machine has the advantages of simple operation, beautiful welding seam, fast welding speed and no consumables. It can perfectly replace traditional argon arc welding, electric welding and other processes for welding thin stainless steel plates, iron plates, galvanized plates and other metal materials. The handheld laser welding machine can be widely used in the complicated and irregular welding processes of cabinets, kitchens and bathrooms, stair elevators, shelves, ovens, stainless steel door and window guardrails, power distribution boxes, stainless steel home appliances and other industries.

Laser welding has high aspect ratio, small weld width, small heat-affected zone, small deformation, and fast welding speed; the weld is flat and beautiful, no treatment or simple processing procedures are required after welding; the optical fiber laser has high electro-optical conversion efficiency, which can be as high as Less than 25%, extremely low energy consumption; long life of optical components, basically maintenance-free; ergonomic handheld welding head, simple operation; precise control, small focus spot, high positioning accuracy, and automatic laser welding can be realized. The operation is simple, that is, training is on the job. The operator only needs to control the computer software to drive the laser welding machine to complete automatic or semi-automatic spot welding, butt welding, stack welding, sealing welding, and it can also target complex plane straight lines and circles. Arc and arbitrary trajectory welding.