Popular science: daily maintenance of handheld laser welding machine

When it comes to laser welding, basically friends who are doing "metal" have to contact. With the development of laser cutting, laser welding is now derived, subverting the traditional welding process.

Hand-held welding machine is hand-held welding, flexible and convenient work, simple operation, welding distance is not restricted, equipped with professional welding software, heat-affected area is small, no deformation, no blackening, large welding depth, and strong welding. Meet the welding needs of various types of metal plates.

With the development of my country's industrial technology, laser welding has become more and more widely used. Since the second half of last year, handheld laser welding has gradually gained popularity and has become a bright spot in the laser welding market in the first half of this year.

Features of handheld laser welding machine

Hand-held laser welding machines on the market generally have the advantages of simple operation, beautiful welds, fast welding speed, and no consumables. They can weld thin stainless steel plates, iron plates, galvanized plates and other metal materials, which can perfectly replace traditional argon arc welding. , Electric welding and other processes. The handheld laser welding machine can be widely used in the complicated and irregular welding processes of cabinets, kitchens and bathrooms, stair elevators, shelves, ovens, stainless steel door and window guardrails, power distribution boxes, stainless steel home appliances and other industries.

According to industry insiders, handheld laser welding is fast, 2-10 times faster than traditional welding. A laser welding machine can save at least 2 welders a year. The welding seam of handheld laser welding is smooth and beautiful, which reduces the follow-up grinding process and saves a lot of time and cost. The laser welding workpiece has no deformation, no welding scar, and the welding is firm. In addition, the laser welding consumables are few, and the service life is long.

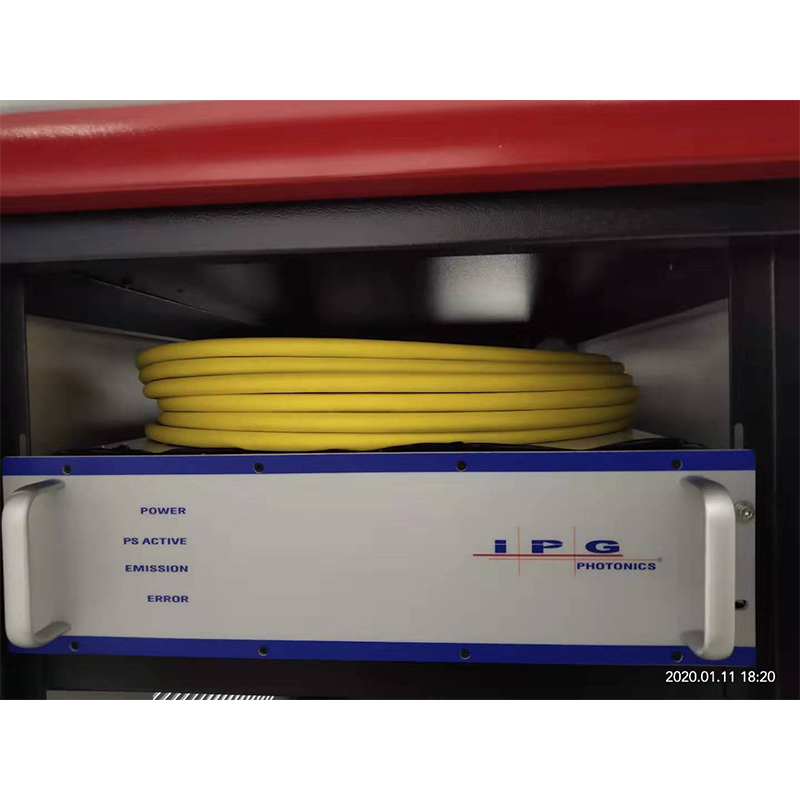

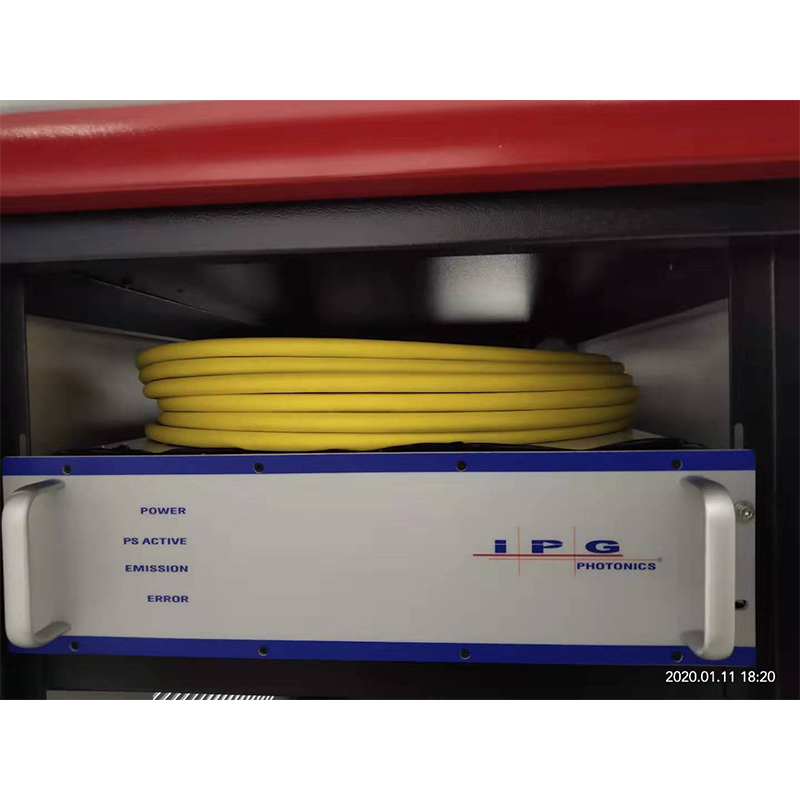

Handheld laser welding machine

Next, please follow the editor to take a look at the precautions for the daily operation of the handheld laser welding machine and the maintenance work that needs to be done!

Maintenance of welding machine

1. Do a good job of testing regularly.

2. Since the welding machine is forced air-cooled, it is easy to inhale dust from the surrounding and accumulate in the machine. Therefore, we can regularly use clean and dry compressed air to blow away the dust inside the welding machine.

3. Regularly check the wiring position of the power wiring.

4. In the annual maintenance and inspection, comprehensive repair work such as replacement of defective parts, repair of casing and reinforcement of insulation deterioration parts shall be implemented.

Hand-held welding manual operation

1. Hand-held laser welding machinists must undergo professional training, understand the use of system indicators and buttons, and be familiar with the most basic equipment knowledge;

2. Check the working wire groove before hand-held laser welding machine work, the wire is not damaged and exposed; the robot body, external shaft, gun cleaning station, and water cooler are strictly prohibited from placing sundries, tools, etc.;

3. It is strictly forbidden to place liquid objects and flammable objects on the control cabinet, and the temperature of the operating room shall not exceed 25 degrees Celsius, and there is no leakage of air, water, or electricity.

Maintenance of welding gun

1. Regularly check and replace the contact tip

2. Regularly clean and replace the spring hose

3. Inspection of insulating ferrule

The regular maintenance and inspection work implemented above can reduce the occurrence of laser welding failures. Although it takes some time and energy, it can extend the life of the welding machine and increase the efficiency of the operation, ensuring the performance of the welding machine and improving safety. . In addition, in the process of using a hand-held laser welding machine, safety protection cannot be ignored.