With the improvement of people's living standards, the problems of high emission and high pollution of traditional fuel vehicles have attracted increasing attention, which has brought broad opportunities for new energy vehicles.

In the manufacturing process of lithium batteries or battery packs for new energy vehicles, there are more than 20 processes that need to be welded to achieve conductive connection or sealing. The quality of welding plays a vital role in the safety of the entire vehicle.

1. Welding the battery cap

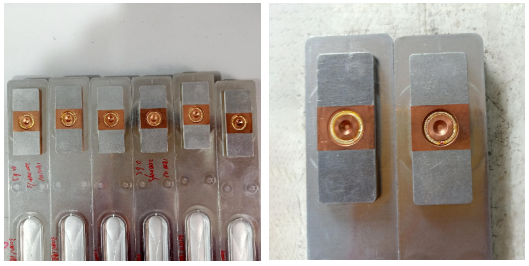

The 18650 battery is a lithium-ion cylindrical battery, which is mainly used in Tesla's new energy vehicles. The battery cap is used as the electrode of the battery and needs to be welded integrally with the battery substrate. The 0.3mm stainless steel cap is welded to 0.5 aluminum. The welding bead is required to be bright and the welding tension value is above 200N.

Using Chuangxin continuous fiber laser for swing welding, better than YAG spot welding, the welding firmness and sealing are better, the welding bead is larger, the contact surface of the cap and the battery substrate is larger, the welding bead is bright white, and the welding tension value is more than 255N .

Welding effect of battery cap

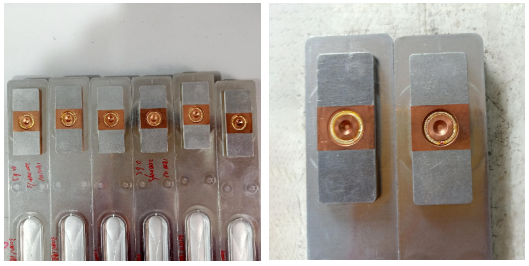

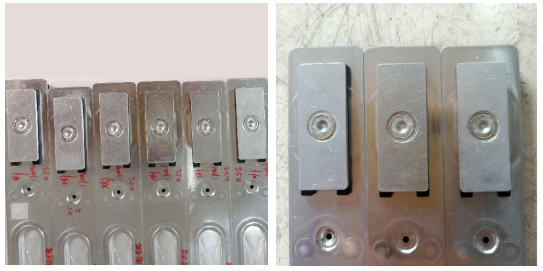

2. Welding of positive and negative poles of power battery

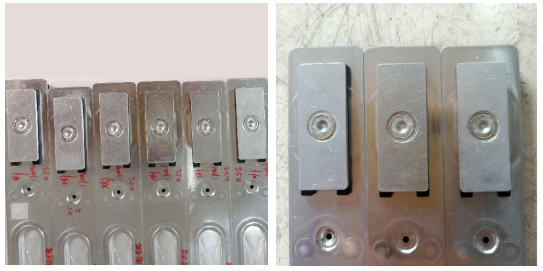

For rectangular batteries, each battery needs to be connected in series and parallel with positive and negative electrode poles to form a battery module unit. Therefore, each battery needs to be welded with a pair of positive and negative poles. The material of the negative pole pole is copper, and the material of the positive pole pole is aluminum. The weld bead is required to be round and not black, with a melting width of 1.2mm, a penetration depth of 0.5mm, and a firm weld.

The battery poles are made of copper and aluminum, which are highly reflective materials. They require good laser beam quality and high energy density for complete penetration and firm welding. Using Chuangxin laser fiber laser for swing welding, the contact area is larger, the surface of the positive and negative electrodes of the welded sample basically maintains the color of the base material, the smoothness is bright, the pole is completely welded, and the welding with the battery cell is firmer.

Negative pole welding effect

Positive pole welding effect

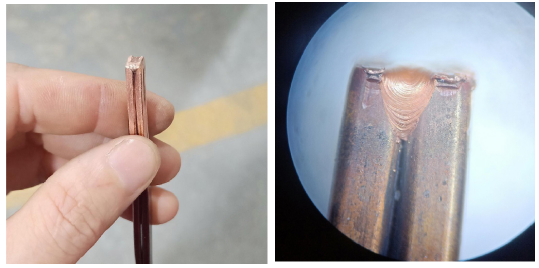

3. Copper PIN welding of motor stator

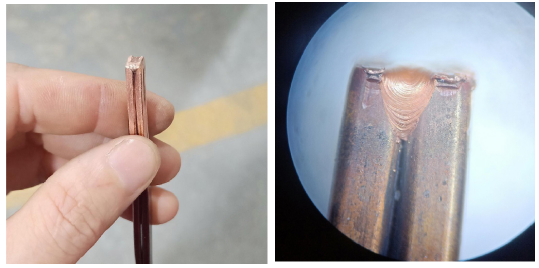

The power source of a new energy vehicle is transformed from the engine of a traditional fuel vehicle to an electric motor, which is mainly composed of a stator and a rotor. The copper PINs inside the stator need to be welded together, the melting width is required to be small, the penetration depth is greater than 3mm, the test shear force is greater than 400N, and the paint layer should not be burnt during welding.

The stator PIN is made of red copper, and the penetration and shearing force requirements are high. The high beam quality continuous fiber laser welding is used to ensure a deep penetration under a small enough melting width to ensure sufficient firmness and high-speed rotation of the motor There is no disconnection between the stator PINs. It can be seen from the effect of Chuangxin laser fiber laser welding motor stator copper PIN that its melting width, penetration depth, shear force and welding surface appearance all meet the welding requirements of new energy vehicles.

Electric motor stator copper PIN welding effect

Lasers for welding in the new energy automobile industry: 1500W-6000W

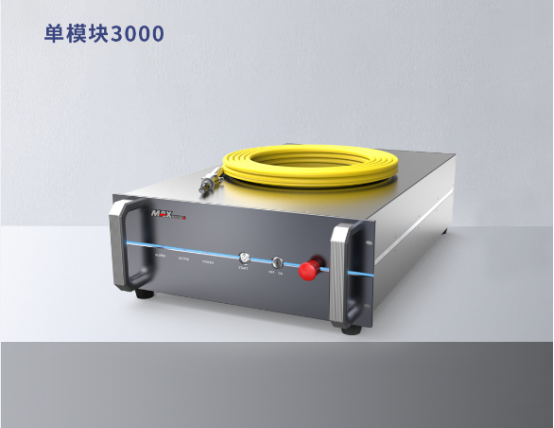

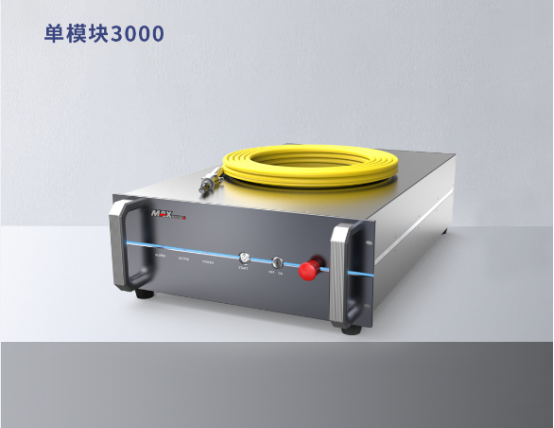

MAX Laser Single Module 3000

1. Small size, saving processing system and air-conditioning room space;

2. Less power consumption, more light and less electricity;

3. Convenient integration, suitable for more application scenarios;

4. The beam quality is good and the processing effect is better.

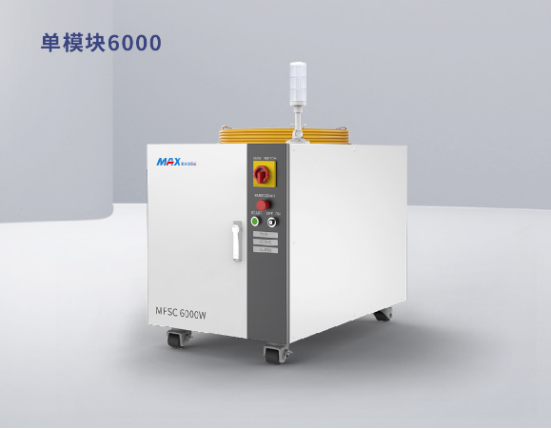

MAX Laser Single Module 6000

1. Small size, reducing the space and weight of the entire processing system;

2. Less power consumption, more light and less electricity;

3. At the same time, taking into account the processing capacity of thick and thin plates, the efficiency of thin plate processing is significantly improved;

4. It is widely used in the fields of new energy, 3C, precision machining of metal drilling, cutting, welding and so on.