Since the outbreak of the epidemic, masks have become a daily necessity at this stage. However, the huge demand gap has allowed some illegal vendors to take advantage of it, and a large number of low-quality masks have flowed into the market, and entries related to "fake masks" and "mask fraud" have repeatedly appeared in hot searches. Fake masks not only have no protective effect, but also have the risk of contamination due to substandard production environmental hygiene, which is extremely harmful to personal health. The most direct way to identify genuine and fake masks is to check the laser anti-counterfeiting marks.

For boxed 3M N95/KN95 series masks, it can be identified by the anti-counterfeiting label on the mask box. The label of the real mask will change color from different angles, while the label of the fake mask will not change color. For bulk 3M N95/KN95 series masks, the authenticity can be distinguished by observing the font on the mask. The real 3M mask text is marked by laser with diagonal lines, while the fake is printed by ink with dots (marks of uneven ink).

In fact, laser marking anti-counterfeiting technology can not only be used to identify the authenticity of masks, but also play a huge role in packaging anti-counterfeiting and traceability in the fields of food, medicine, tobacco, beauty, and electronic products. It can be said that laser marking Anti-counterfeiting has been integrated into all aspects of our lives. So why can laser marking play such a huge role in the packaging anti-counterfeiting market? What advantages does it have compared to traditional methods?

Why is laser: the characteristics and application advantages of laser marking anti-counterfeiting

The basic principle of laser marking is to use high-energy-density laser beams to act on the surface of the material. By focusing, the surface material is instantly vaporized or changed in color, and the path of the laser on the surface of the material can be controlled to form the required permanent image. Text mark. Because laser marking can produce various characters, symbols and patterns, and the size of characters can range from millimeters to micrometers, this has special significance for the anti-counterfeiting of products, so it has a wide range of applications in the anti-counterfeiting market.

Before the large-scale application of laser marking, the marking on the package was usually printed with ink. The marks printed by this traditional method are easy to fall off and blur over time, are easy to be tampered with, and cannot perform high-precision operations. Although it has advantages in equipment cost, the continuous cost of consumables (ink) is high, and it will cause certain pollution to the environment.

Take the most common food packaging as an example. Because the marks printed by traditional methods are easy to erase and fall off, some criminals print some expired or even fake products with brand trademarks, or modify the production date to make these unqualified products Circulate in the city. This kind of phenomenon is widespread in grain and oil, beverages, snacks, sauces and other fields. In addition, for some paper food packaging, harmful substances in ink may also penetrate the packaging and contaminate the food, posing a threat to the health of consumers.

Beverage bottle caps, food packaging marking

Picture from the official website of Inno Laser

The emergence of laser technology has solved a series of problems caused by traditional ink printing. For food packaging, the use of laser marking has the advantages of non-toxic, non-polluting, high efficiency, high definition, exquisite patterns, and never falling off. In addition, laser marking can also be combined with computer technology, and by connecting to a database system, we can track and query detailed information such as the delivery and circulation of food in time to ensure that we can eat with confidence.

The medical industry is inseparable from the escort of laser marking. Since medical products are in direct contact with the human body and are related to the lives and health of the people, the anti-counterfeiting and anti-counterfeiting of medical products has become the top priority of protecting the health and safety of consumers.

Marking of pharmaceuticals and metal surfaces

Picture from the official website of Inno Laser

In addition to the features mentioned above, the marking of medical devices and drugs also has some special requirements. For example, for common pills and soft capsules, lithographic printing will produce pressure on the product, and non-contact laser marking will not deform the capsule, and can mark even more minute information on the tiny pills. On the medical equipment represented by stainless steel surgery and dental equipment, the laser can mark on an absolutely smooth surface, which can prevent bacteria from adhering to the surface, and the marked surface will not damage the corrosion-resistant chemical passivation treatment , Can make the anti-corrosion coating exist even after years of use and countless times of cleaning and disinfection. Another example is the 3M mask mentioned at the beginning. Whether there is a laser mark is an important sign to distinguish between authenticity and fake.

Laser marking is also different: the unique advantages of UV lasers in food and medical applications

As we all know, there are many types of lasers, and their applicable materials are also different. For example, fiber lasers are suitable for all kinds of metal materials, CO2 lasers are suitable for most polymer materials, and ultraviolet lasers are suitable for more precise and demanding application scenarios.

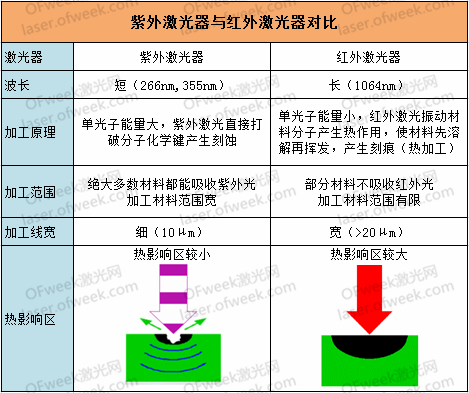

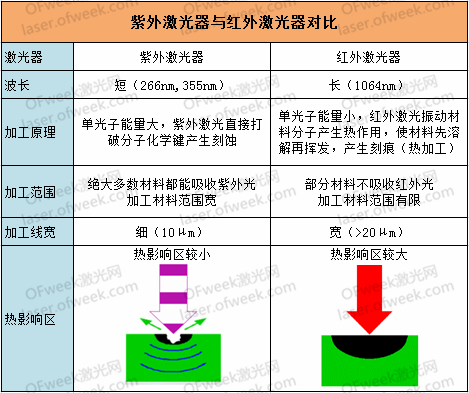

In fact, CO2 and fiber lasers have already developed marking applications. The light emitted by these lasers is in the infrared band. The essence of the marking process is to heat the material to bleach, carbonize or ablate through thermal interaction to produce color contrast, but this heating will change the heat-affected zone (HAZ) material Chemical structure, carbonization phenomenon occurs or the surface is not smooth. For plastics commonly used in food packaging, because of their low absorption of infrared light, the heat generated by infrared lasers can damage the surface of some packaging materials, so they cannot be used in the food packaging industry on a large scale.

In this context, the advantages of UV lasers have emerged. Most materials absorb ultraviolet light stronger than infrared light, and the photon energy of ultraviolet lasers is higher. When the ultraviolet laser acts on high molecular polymers such as PI, it can directly break the chemical bond of the material, so that the material fragments are discharged in the form of small particles or gas, so as to achieve the purpose of stripping and removing the material. Since most of the energy is used to break chemical bonds, very little energy is converted into heat energy, which basically eliminates the changes in the heat affected zone (HAZ) and surrounding materials. For most white plastics (the pigment is TiO2), TiO2 will strongly absorb ultraviolet rays and change the crystal structure. This change makes the substance in the corresponding area appear darker, resulting in a smooth, clear and legible mark inside the material.

Comparison chart of ultraviolet laser and infrared laser

OFweek Laser Network Mapping

Representative UV laser companies: sales increased by 177% in 2 years, with a market share of over 20%

Laser marking is one of the largest application areas of laser processing. There are thousands of companies at home and abroad engaged in the production and sales of laser marking machines, and the market demand for lasers for marking is also huge. Take UV lasers as an example. In 2015, domestic UV lasers sold about 3,700 units, and in 2018 they reached about 15,000 units, of which nanosecond UV lasers accounted for 80% (about 12,000 units). Sales in 2019 are expected to increase over 2018. 33% (data from the 2019 China Laser Industry Development Report).

With the rapid expansion of the UV laser market, domestic companies have also made great progress. According to OFweek Laser Network, the sales volume of Innolaser's nanosecond ultraviolet laser reached 2,633 units in 2018, accounting for approximately 21.94% of domestic sales that year, leading the country. In 2016, the sales volume was only 947 units (a 2 year increase of 177%). In September 2019, Innolaser's FORMULA series high-power ultraviolet nanosecond laser technology was assessed as the international advanced level by the China Science and Technology Co-Creation (Beijing) Science and Technology Achievement Evaluation Center, and obtained the Ministry of Industry and Information Technology Science and Technology Achievement Registration Certificate.

FORMULA series laser (left), FOTIA series laser (right)

Picture from the official website of Inno Laser

According to the official website of Inno Laser, the highest average power of the FORMULA series of integrated high-power lasers can reach 25W, energy pulse>500μJ, beam quality M2<1.2, repetition frequency adjustable within the range of 30~300kHz, and products with more than 30W can be customized according to requirements . In addition, Innolaser also has compact medium and low power lasers of the FOTIA series. The power can be adjusted within the range of 500mW~10W according to user needs, the repetition frequency can be adjusted within the range of 30kHz~300kHz, and the beam quality M2<1.2 can be used for 3D printing. , Static and dynamic marking, PCB/FPC cutting, glass engraving, laser resistance adjustment and other fields.

Fiber lasers currently dominate the laser processing market, but UV lasers are also becoming an important force in the laser processing market. Especially the anti-counterfeiting market, which has attracted people's attention due to the anti-counterfeiting of masks, will bring new development momentum to ultraviolet lasers. In addition, the prices of UV lasers and laser marking machines continue to drop, which will also reduce the initial investment costs of users, which will help promote the further popularization of UV lasers in domestic laser processing.