What are the differences between various light sources of laser cutting machines such as green light/infrared/ultraviolet and other laser applications

The laser cutting machine is to focus the laser emitted from the laser into a high power density laser beam through the optical path system. The laser beam is irradiated on the surface of the workpiece, making the workpiece reach the melting point or boiling point, while the high-pressure gas coaxial with the beam blows the molten or vaporized metal away. With the movement of the relative position of the beam and the workpiece, the material is finally formed into a slit, so as to achieve the purpose of cutting.

Laser cutting machine is an important tool in the cutting field, known as a very fast "knife". The principle is to irradiate the surface of the material with a high-density and high-energy laser beam to melt, vaporize, ablate or reach the ignition point, and at the same time, the molten material is blown away by the high-speed airflow coaxial with the beam, so as to realize the cutting of the workpiece and form a cut.

At present, there are many kinds of lasers on the market, which are divided into various light sources, such as: green light, infrared light, ultraviolet light, etc. Each light source has different advantages and is applied to various materials. Laser cutting can be divided into four categories: laser vaporization cutting, laser melting cutting, laser oxygen cutting and laser scribing and controlled fracture.

So, what are the differences between the various light sources of laser cutting machines such as green light/infrared/ultraviolet and other laser applications?

Analysis of the difference between various light sources of laser cutting machines such as green light/infrared/ultraviolet laser applications:

Several light sources commonly used in laser cutting machines, optical fiber (red light), purple light (ultraviolet), green light, etc., different light sources are applied to different materials, according to the characteristics of the material to be processed, the thickness of the material, the processing quality requirements and The higher the requirements for laser beam quality and thermal influence, the absorption of the laser band is different, and the selected laser cutting machine will also be different.

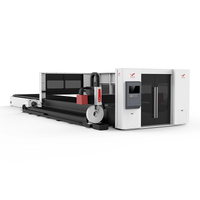

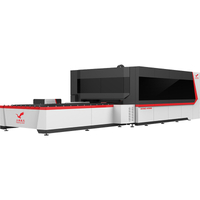

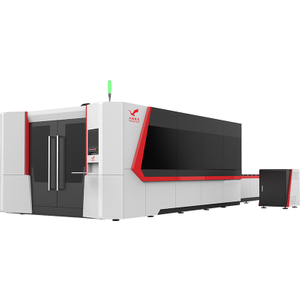

1. Optical fiber (red light) of laser cutting machine light source:

Fiber laser refers to a laser that uses rare earth element-doped glass fiber as the gain medium. The wavelength of the fiber is 1064nm, which has high stability, high precision, fast running speed, low processing cost, high laser power, and can cut materials. There are many types, suitable for the processing of large products; optical fiber applicable materials: stainless steel plate, aluminum substrate, ceramic substrate, copper substrate, PCB, ceramic sheet, carbon steel, aluminum alloy, brass, copper, pickling plate, galvanized plate , silicon steel plate, electrolytic plate, titanium alloy, manganese alloy, etc., suitable for cutting various metal materials.

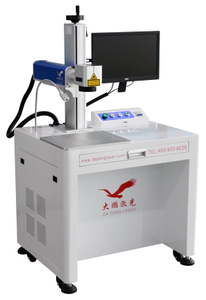

2. Ultraviolet (purple) light source of laser cutting machine:

Ultraviolet laser 355nm wavelength, the products of this wavelength belong to the all-round type, and its light spot is also small. Due to the special UM wavelength, it has the title of all-rounder in the traditional processing field, laser marking, laser cutting, laser welding can be seen His figure, fiber laser can not sit, it can do, it can also be processed by C02, it performs well in ultra-wave cutting, and can achieve burr-free, neat and smooth, fast speed for micro and ultra-thin cutting of metal products , low energy consumption and other advantages. Applicable materials for purple light: cover film, FPC soft board, PCB soft and hard board, FPC auxiliary material, ultra-thin metal, ceramic, polymer material, resin, silicon wafer, PET/PI/PP film, plastic film, copper foil, explosion-proof film , Electromagnetic film, Sony glue and other flexible films.

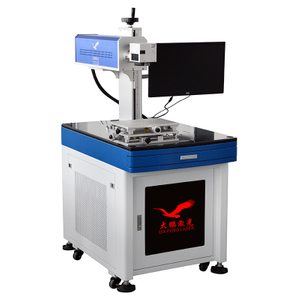

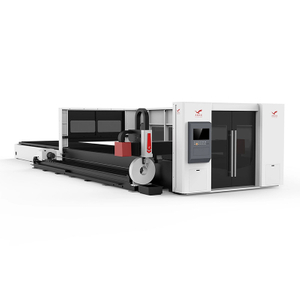

3. Green light of laser cutting machine light source:

The wavelength of green light is 532nm. It has a small spot and a shorter focal length. It belongs to the cold working mode and plays an irreplaceable role in precision cutting, especially in circuit boards, glass, ceramics, jewelry, glasses and other industries. their figures. Applicable materials for green light: precision cutting of cover film, FPC soft board, PCB soft and hard board, PET/PI/PP and other flexible films, ultra-thin glass, ceramic substrates and other materials.

Fiber laser cutting machines are mainly used in the metal cutting industry. At present, the production of the circuit board industry is basically UV and green light cutting machines, since they are all circuit board cutting applications. The main difference between UV laser cutting machine and green laser cutting machine lies in the cost of equipment, processing efficiency, processing effect and processing purpose.

Ultraviolet laser cutting machine can take into account FPC soft board cutting, IC chip cutting and some ultra-thin metal cutting in the PCB field, while high-power green laser cutting machine can only do PCB hard board cutting in the PCB field. Although cutting can also be done on boards and IC chips, the cutting effect is lower than that of UV lasers. Compared with the UV laser cutting machine, the green laser cutting machine has a lower price and higher processing efficiency in the early stage, but as the power of the UV laser cutting machine continues to rise, this advantage is gradually equalized. In the processing effect, the thermal effect is smaller and the effect is more ideal.