Which fields are suitable for hand-held laser welding? What to pay attention to when using a handheld laser welder

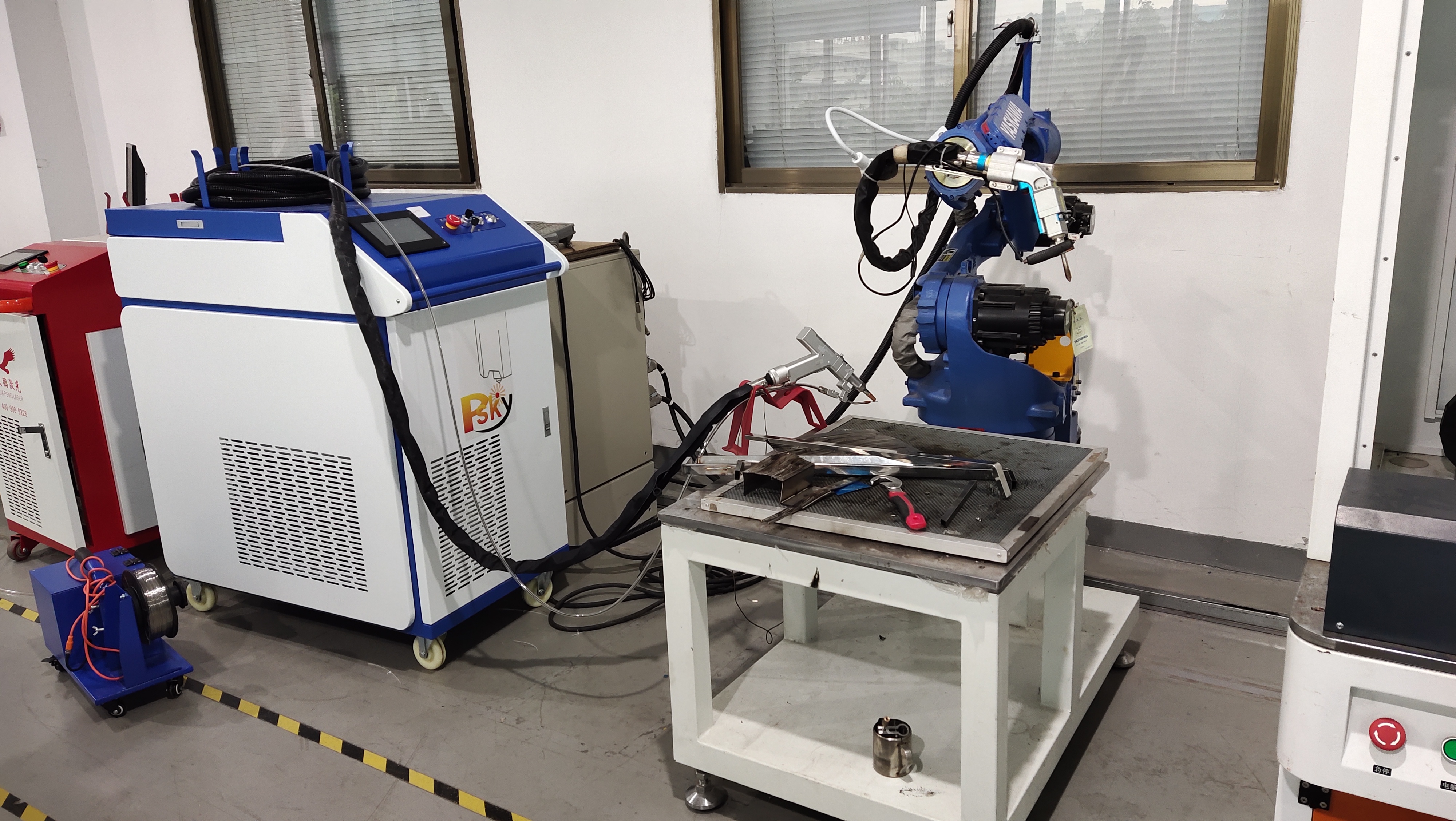

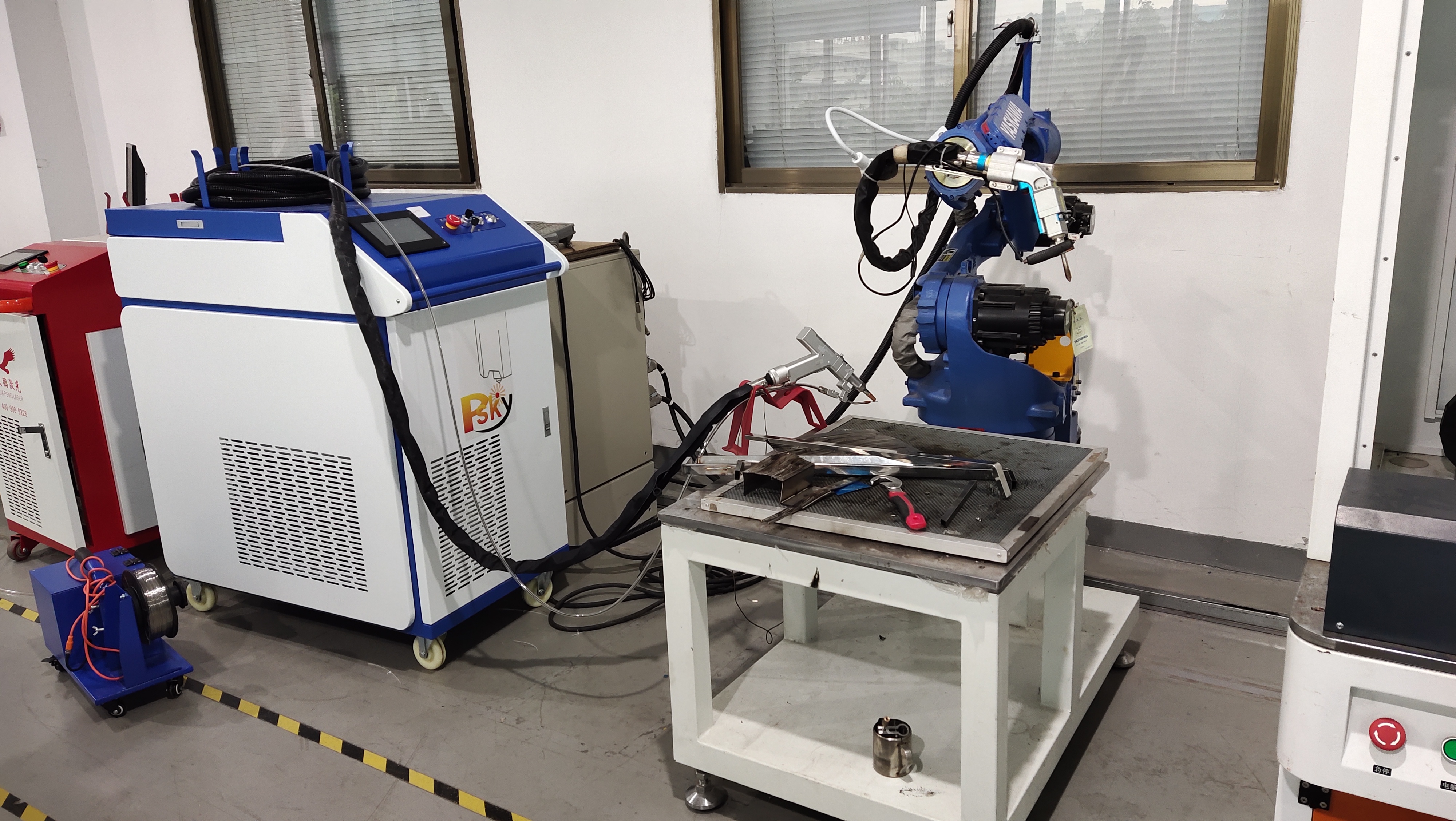

Hand-held laser welding machine is one of the growth points of the rapid rise in the laser field in recent years. With many advantages such as high efficiency, short training time, environmental protection, less consumables, and high scalability, it has been recognized by the market.

At present, the application fields of hand-held laser welding are mainly concentrated in the welding process of sheet metal, cabinets, water tanks, power distribution boxes and other cabinets, cabinets, kitchens and bathrooms, stainless steel door and window guardrails and other complicated and irregular welding processes that do not require fixtures. Compared with traditional argon arc welding and electric welding processes, handheld laser welding is not only energy-saving (saving about 80% to 90% of electric energy than argon arc welding), or the welding speed of thin stainless steel plates, iron plates, aluminum plates and other metal materials It has obvious advantages in terms of welding quality, subsequent processing (which can greatly reduce the labor cost of polishing and leveling procedures), so there is a strong potential for replacing traditional processes.

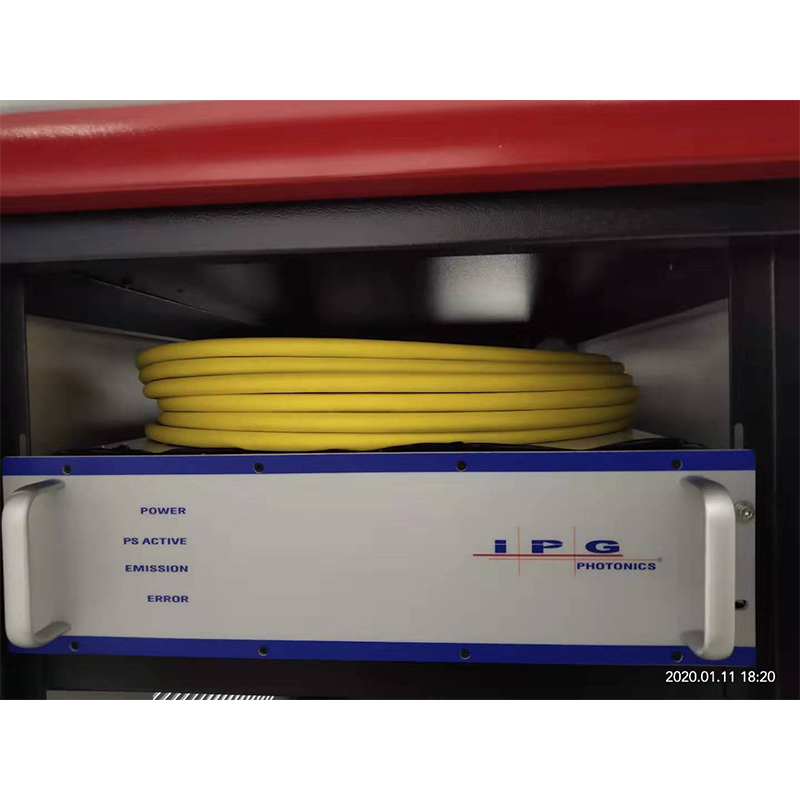

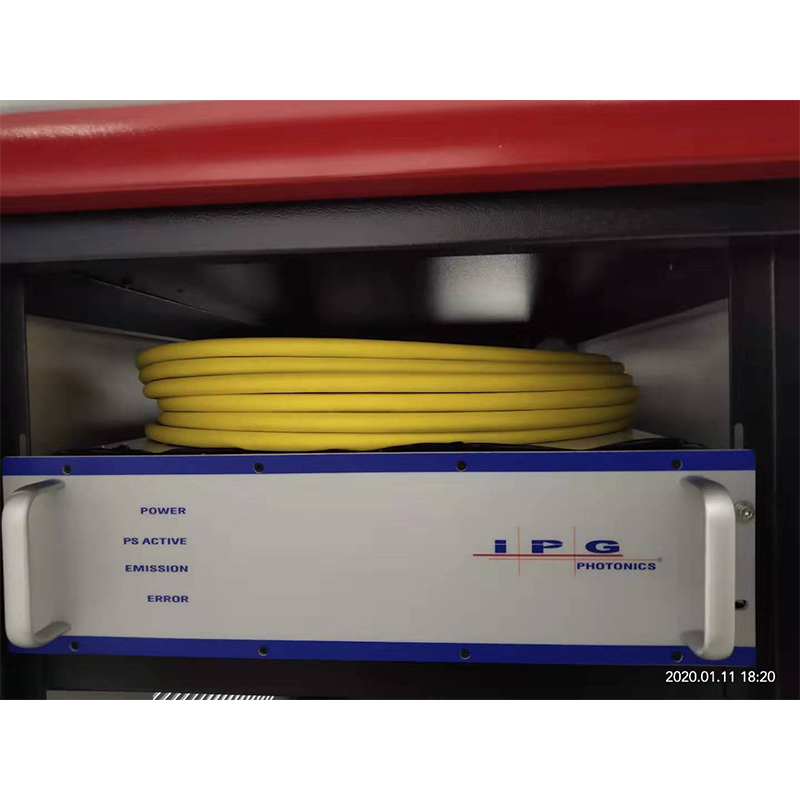

Laser welding is a welding method in which a high-energy laser beam is used as a heat source, and the material is heated by radiation to the surface of the material, and the material is melted and connected through heat conduction. Because laser welding has the advantages of high precision, small heat-affected zone, small deformation, and high efficiency, it has a good development prospect. With the continuous development of laser technology and numerical control technology, laser welding has become an advanced processing method in the field of industrial sheet welding.

Hand-held laser welding belongs to four types of laser products (greater than 500mW), which is harmful to the skin and eyes. However, many workers in domestic processing plants cannot see the laser and the sparks during processing are not dazzling, so they are performing hand-held welding. There are often no safety protection measures during operation. This is a very dangerous practice. Although the human eye cannot directly see the laser in the infrared band (the common wavelength of fiber lasers is 1064nm), there is a certain angle between the welding head and the workpiece surface for hand-held welding, and some of the laser light will be reflected, especially for welding copper, aluminum and other high-reflectivity. The laser energy reflected by the material is greater, and if it is reflected into the eyes, it will cause irreversible damage to the retina. Therefore, we hereby call upon users who hand-held laser welding to wear laser goggles!

In the thinner plate welding industry, the handheld laser welding machine has become a new industry technology that is beloved by the market by virtue of its advantages of simple operation, high efficiency, and smooth and beautiful welds. Hand-held laser welding machines are widely used, but many people want to ask what materials can be welded by hand-held laser welding machines?

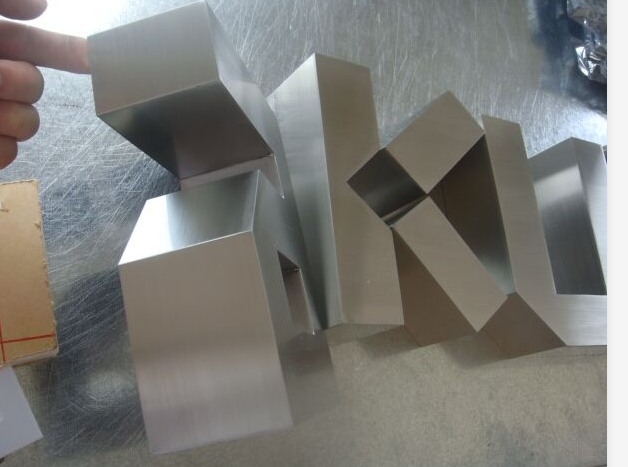

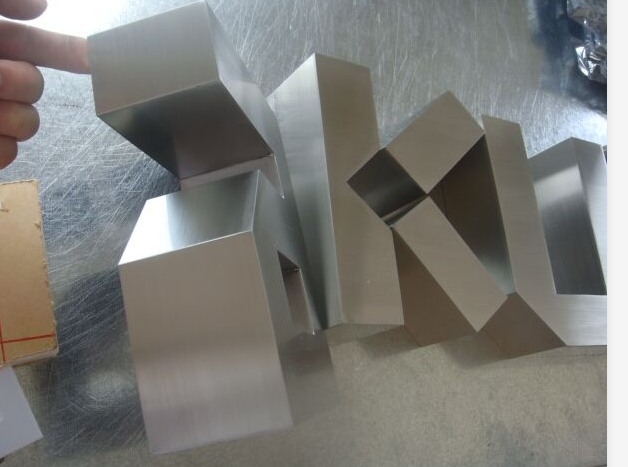

1. Stainless steel

The coefficient of thermal expansion of stainless steel is high, and it is easy to overheat during welding. When the heat-affected area is slightly larger, it will cause serious deformation. However, the hand-held laser welding machine generates low heat during the entire welding process. Coupled with the relatively low thermal conductivity, high energy absorption rate and melting efficiency of stainless steel, a well-shaped, smooth and beautiful weld can be obtained after welding.

2. Carbon steel

Ordinary carbon steel can be welded directly by hand-held laser welding. The effect is comparable to stainless steel welding, and the heat-affected area is smaller. However, when welding medium and high-carbon steel, the residual temperature is relatively high, so it is still necessary before welding. Preheating, heat preservation after welding to eliminate stress and avoid cracks. Here can be said that the cold welding machine, medium and high carbon steel can be welded or repaired at a slow speed using cold welding with cast iron welding wire. The focus is on temperature control, temperature control, and temperature control. The cold welding machine teaches handheld laser welding more on the residual heat after welding. excellent.

3. Die steel

The handheld laser welding machine is suitable for welding various types of die steel, and the welding effect is very good.

4. Aluminum and aluminum alloy

Aluminum and aluminum alloys are highly reflective materials. Porosity may occur in the molten pool or at the root during welding. Compared with the previous metal materials, aluminum and aluminum alloys have higher requirements for parameters, but as long as the selected welding parameters are appropriate , You can get welds equivalent to the mechanical properties of the base metal.

5. Copper and copper alloy

The thermal conductivity of copper is very strong, and it is easy to produce incomplete penetration and partial lack of fusion during welding. Usually, the copper material is heated during the welding process to assist the welding. Here I am talking about thin copper materials. Hand-held laser welding can Direct welding, because of its concentrated energy and fast welding speed, the high thermal conductivity of copper has little effect on it.

6. Welding between dissimilar materials

Hand-held laser welding machine can be carried out between a variety of dissimilar metals, such as copper-nickel, nickel-titanium, copper-titanium, titanium-molybdenum, brass-copper, low-carbon steel-copper and other dissimilar metals. Laser welding can be carried out under conditions (gas or temperature).