Application of Laser Welding in Kitchenware Industry----Handheld Laser Welding Machine

Principle of laser welding

As a high-quality, high-precision, low-distortion and high-efficiency welding method, laser welding is widely used in machinery manufacturing, aerospace, automotive industry, powder metallurgy, biomedicine, etc., especially in the kitchenware industry represented by stainless steel kitchenware The application is more extensive.

Laser welding is to radiate a laser beam with high energy density to the metal surface. Under the interaction between the laser and the metal, the metal absorbs the laser energy and converts it into heat energy. After the metal is melted, it cools and crystallizes to form a weld. Laser welding has the advantages of fast welding speed, small workpiece deformation, large weld fusion, good weld quality, and simple post-weld processing. It can be used to weld the same or dissimilar materials or refractory materials in various environments. The schematic diagram of laser welding is shown in Figure 1.

Figure 1 Schematic diagram of laser welding

In the processing of stainless steel kitchen utensils, in order to achieve better welding results, more and more kitchen utensils companies use laser welding technology. After welding, the deformation of the workpiece is small, and the subsequent processing workload is small, which can obtain a very beautiful welding surface effect, and can greatly reduce the labor cost of polishing and leveling processes.

Laser welding equipment commonly used in the kitchenware industry

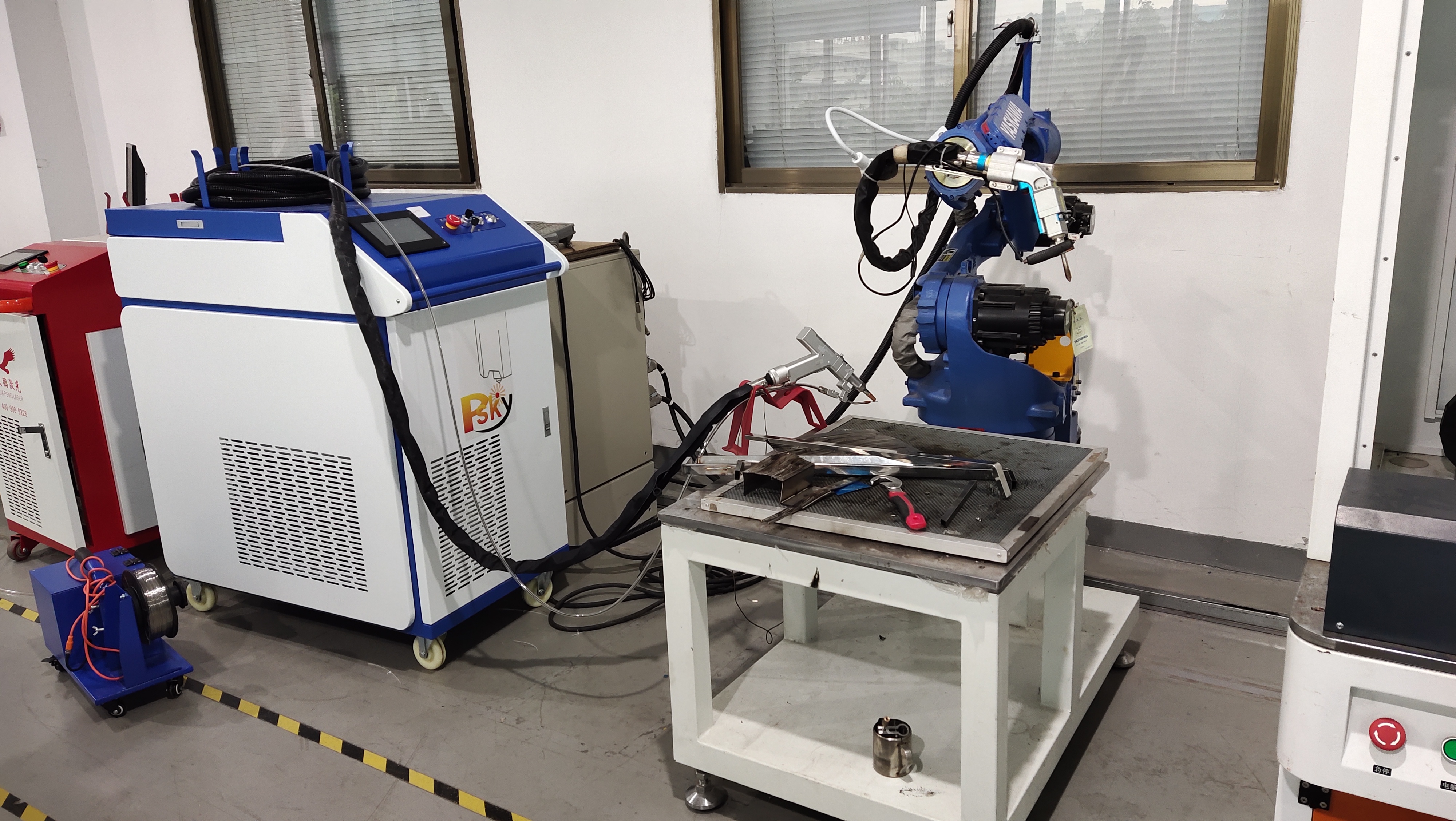

The most commonly used laser welding equipment in the kitchenware industry is generally divided into three types: double-station robot laser welding unit, laser welding machine and hand-held laser welding machine.

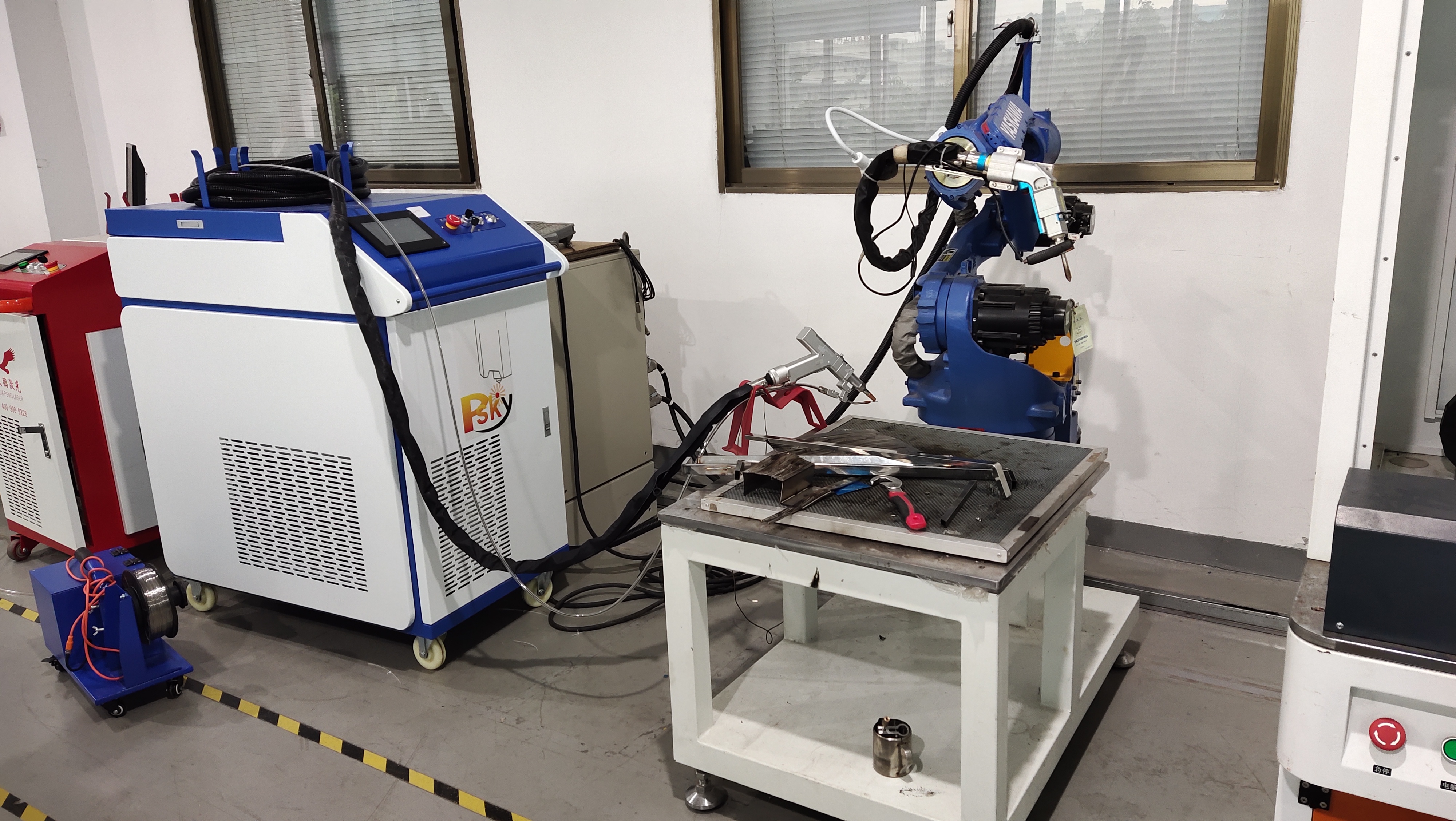

Double station robot laser welding cell

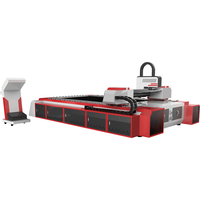

The dual-station robot laser welding unit is shown in Figure 2. It consists of a robot, a dual-station rotary positioner, a laser, and a protective room. The manual feeding method is used to realize internal welding and external loading and unloading, and improve the efficiency of equipment use. and production efficiency. Usually, the rotary positioner is equipped with adjustable fixtures to meet the welding of workpieces of different specifications, and has strong versatility. This welding unit is mainly suitable for the welding of medium and large kitchen utensils with many long welds.

Figure 2 Dual-station robot laser welding cell

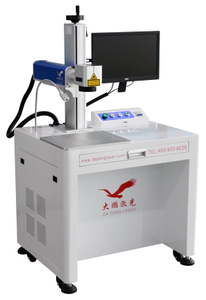

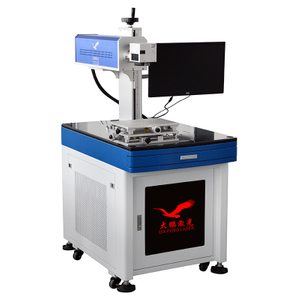

Laser welding machine

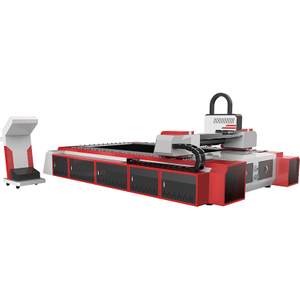

As shown in Figure 3, the laser welding machine is mainly composed of X, Y, Z three axes and rotating axes, laser, closed cover, etc. The welding of workpieces is realized by manual loading and unloading. This special welding machine is mainly suitable for the welding of small kitchen utensils with a single welding seam. The rotating shaft is equipped with different fixture systems to adapt to a variety of workpieces, with high flexibility.

Figure 3 Laser welding machine

Handheld Laser Welding Machine

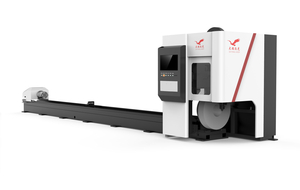

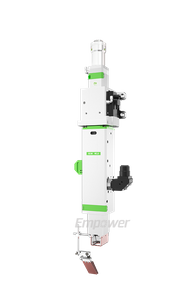

The hand-held laser welding machine is shown in Figure 4. It is mainly composed of a laser, a water cooler, a hand-held welding head, etc. It occupies a small area, is quick to use, and has low requirements for operators. The initial cost investment is less, and the grinding workload after welding of stainless steel kitchen utensils can be greatly reduced. Therefore, hand-held welding machines are currently the first choice for small kitchen utensil manufacturers.

Figure 4 Handheld Laser Welding Machine

Design Ideas of Fixtures for Laser Welding of Typical Workpieces

The use of laser welding in the kitchenware industry has become a development trend. Some domestic manufacturers have applied laser welding to the welding of hardware kitchenware, especially the welding of the covers of large kitchenware such as range hoods and ovens, which has greatly improved production efficiency. good welding effect. The following takes the laser welding of the range hood hood as an example to briefly analyze the design ideas of the fixture.

The model and real object of the range hood are shown in Figure 5. The range hood is generally cut and stamped by laser cutting, and the consistency of the workpiece is kept well. The design ideas of fixtures for such workpieces are generally as follows:

Figure 5 Range hood hood

First, determine the position of the workpiece, and find the positioning datum according to the requirements of the drawing. Since the hood is very loose after stamping and forming, the side edge cannot be used for positioning, and the positioning method of hole + large surface is generally adopted.

Determine the number of welds and the ease of welding. In the case of ensuring the size of the workpiece, the welding of long seams is given priority. If the short seam affects the fixture design, resulting in high cost, it is necessary to communicate with the customer whether follow-up repair welding can be adopted in combination with the cost.

Determine the welding fixture form. Determine the degree of automation of the fixture according to customer needs, whether to use manual clamping, automatic clamping, or a combination of manual clamping and automatic clamping.

Make sure that the fixtures are easily adjustable. In order to ensure the convenient adjustment of the designed tooling positioning block and clamping block, the form of adjustment shims or waist hole adjustment, pin positioning, etc. can be used to reduce the amount of rework of the tooling and fixture parts.

The manual clamping tool for the cooker hood that has been normally used at the customer's site is shown in Figure 6. Due to the increase in customer output, according to the customer's needs, the pneumatic clamping tool is redesigned to improve work efficiency, as shown in Figure 7 .

Figure 6 Manual clamping tool for range hood hood

Figure 7 Pneumatic clamping tool for range hood hood

Handheld laser welding machine has the advantages of simple operation, high efficiency, wide range of weldable materials, and low maintenance cost. Handheld laser welding machine equipment has been widely used in many industries. What are the main applications of hand-held laser welding machines?

1. Stairs and elevators

In the production process of elevators and stairs, especially some details need to be welded with a handheld laser welding machine, which is easy to operate and ensures that every corner can be welded in place, and the aesthetics of stairs and elevators, so the highly rated handheld laser The application of welding machines in stair elevators is also very common.

2. Door and window guardrail

In the process of modern home decoration, more and more stainless steel materials are used, including some stainless steel doors and windows and guardrails, and stainless steel doors and windows and guardrails also need to be welded with welding equipment during the construction process. The highly acclaimed handheld laser welding machine does just that, ensuring that the display of doors, windows and guardrails will not be affected after welding.

Widely used in: gold and silver diamonds, sanitary ware, food packaging, tobacco marking, beer marking, beverage marking, packaging, glasses and watches, auto parts, plastic paper materials, electronic hardware for depth, smoothness, fineness Fields with high degree requirements, such as watches, mold industry, bitmap marking, etc. Widely used in precision instruments, electronic components, home appliances, mobile communications, watches, glasses, jewelry and other industries. It is suitable for stainless steel, carbon steel, copper, aluminum, gold, silver, chromium, nickel, titanium, tantalum and other metals or alloys; it can also be used for welding between various dissimilar materials.

The kitchenware laser welding machine saves about 80% to 90% of electric energy. Compared with arc welding, the processing cost can be reduced by about 30%. It can weld dissimilar steel and dissimilar metal, and easily realize mechanization and automation.

Because the heat input of kitchen utensils is extremely low during laser welding, the deformation after welding is very small, and a very beautiful welding surface can be obtained, and there is little post-welding treatment. The handheld stainless steel laser welding machine can greatly reduce or eliminate huge polishing and finishing. The labor cost on the flat process.