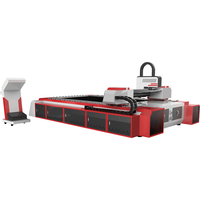

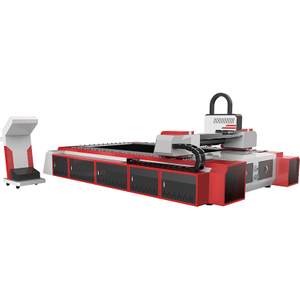

Application solution of laser cutting machine in kitchen and bathroom industry

Laser cutting is used in more and more fields, and more and more materials are applicable. Used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, food machinery, textile machinery, construction machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising , metal external processing, kitchen utensils processing and other manufacturing and processing industries.

Laser cutting machine can cut stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, galvanized sheet, pickling sheet, copper, silver, gold, titanium and other metal sheets and pipes; Metals such as wood, rubber, plastic (polymer), leather and other materials.

So, what are the application advantages of laser cutting machine in the kitchen and bathroom industry? Lixing laser technicians will analyze and answer for you.

Application solutions of laser cutting machine in kitchen and bathroom industry:

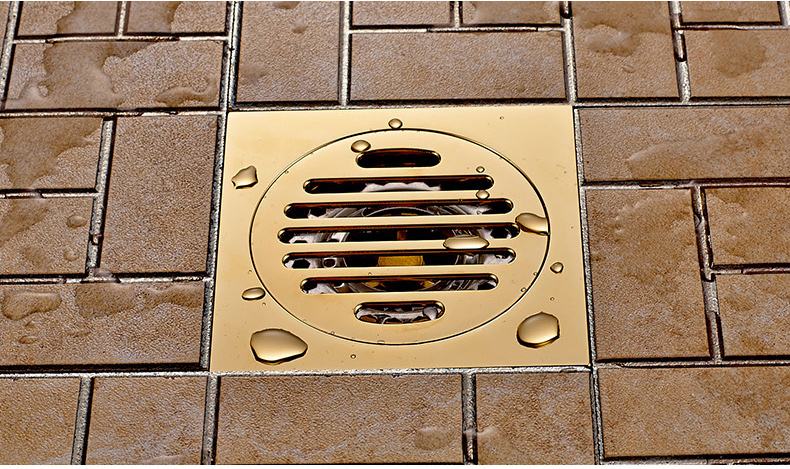

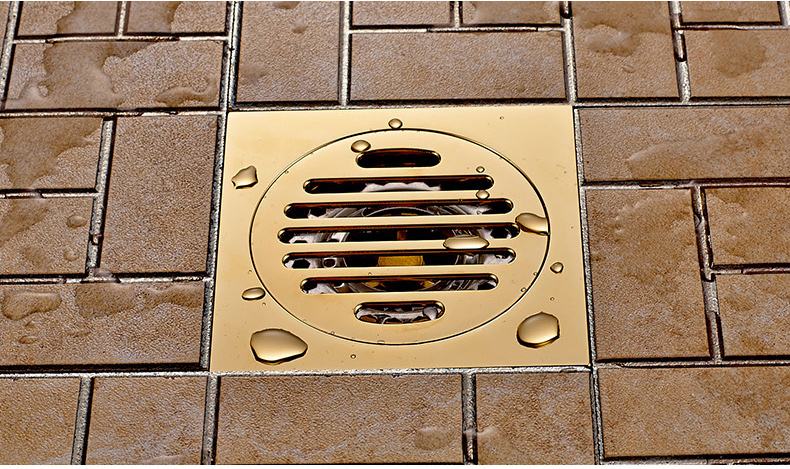

Common kitchen and bathroom products in our lives mainly include cabinets, range hoods, microwave ovens, ovens, disinfection cabinets, vegetable sinks, refrigerators, rice cookers, stoves, gas water heaters, etc., as well as some daily necessities such as showers, sinks, Basin, hardware floor drain, faucet, shower room, mop pool, etc.

Most kitchen and bathroom products are mainly made of stainless steel sheet metal panels with a thickness of less than 3mm, which are widely favored by the market for their corrosion resistance, aesthetics and practicability. The traditional sheet metal processing method is cumbersome, time-consuming, and labor costs are high. Meet the needs of the market. The advent of laser cutting machines has revolutionized the kitchen and bathroom products manufacturing industry. Kitchen and bathroom products are also a part of furniture. Good kitchen and bathroom products can be the icing on the cake for the decoration of the whole family environment, and can also objectively reflect people's life taste and habits. Good kitchenware can also make consumers feel comfortable. , Use it with confidence.

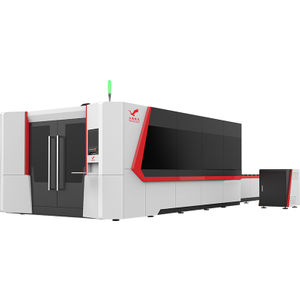

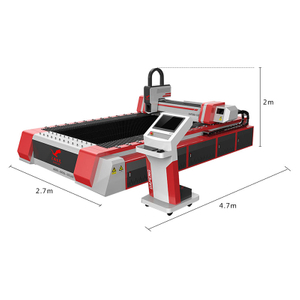

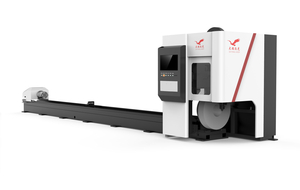

In the process of kitchenware processing, the cutting of stainless steel materials and the pattern engraving of metal surfaces can be automatically programmed and cut by a fiber laser cutting machine. Different from traditional processing methods, laser cutting technology has the advantages of high cutting precision, fast cutting speed, smooth cutting end face, and no need for secondary processing.

Laser cutting does not require molds and knives, which simplifies the processing technology and process, and the production cycle is short, which saves the time and cost of mold opening for enterprises. The labor cost will also be greatly saved. The work that was done by ten people can now be operated by one person. There will be no stamping in the laser cutting machine, no burr on the machined surface, no need for secondary processing, and mass production can be quickly realized for proofing.

Laser cutting technology can well meet the needs of customization in the kitchen and bathroom products market. It not only has fast processing speed, high efficiency, and simple operation, but also can complete plate cutting of various shapes without changing molds or tools, resulting in a shorter production cycle. , without secondary processing, can quickly achieve mass production, saving the cost of consumables and labor costs.

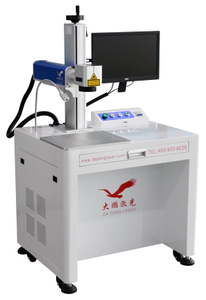

The above is the analysis of the application solution of laser cutting machine in the kitchen and bathroom industry. The main products of Dapeng Laser include laser cutting machine, full CNC hydraulic bending machine, laser welding machine, laser marking machine and laser application automation equipment, etc. Metal processing, chassis cabinets, lighting, mobile phones, 3C, kitchen utensils, bathroom, auto parts machining and hardware industries.