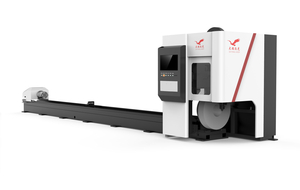

What are the application areas of laser pipe cutting machines?

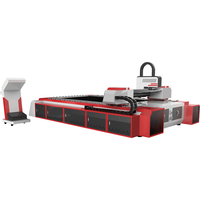

The laser pipe cutting machine is the main equipment for cutting pipes when it is used. Whether it is a square pipe, a round pipe or a special-shaped pipe, it can effectively cut the pipe. It has more advantages than other equipment. With its professional and stable cutting effect, the tube laser cutting machine has quickly occupied various metal processing industries, especially in automobile manufacturing, oil exploration, machinery manufacturing, etc. It has been widely used.

The laser processing of the laser pipe cutting machine is made by computer drawing, which is simple and convenient to operate. In terms of processing graphics, it can complete the flexible processing of any graphics. And it can achieve large-scale, fast and accurate processing. The cutting process can complete multi-step processing at one time, and the cutting speed of pipes that can cut several meters of pipes in one minute is higher than other cutting methods.

Working principle of laser pipe cutting machine:

1. Feeding rack: Before the cutting starts, the whole bundle of pipes needs to be manually hoisted to the material rack, manually packaged and removed, and then placed on the automatic pipe conveying mechanism in sequence.

2. The pipes are placed on the conveying platform in turn, and the pipe conveying device can transfer the pipes to the feeding mechanism one at a time according to the requirements, and automatically replenish and stand by according to the pipes.

3. The feeding mechanism will automatically transfer the pipes in the waiting area to the automatic feeding mechanism according to the signal, and other pipes will be automatically filled and moved to the material position to ensure continuous operation.

4. The pipe positioning and calibration system calibrates the pipe position neatly as needed (the pipe material should not be placed beyond the outside of the feeding mechanism).

5. The feeding structure automatically sends the pipes to the material (lifting) shelving system of the machine tool according to the signal (one pipe at a time).

6. The feeding mechanism returns in time after receiving the signal of completion of shelving, and at the same time, the A rotating gripper device moves according to the signal - clamps - pushes it to the B rotating plate for perfect cutting.

7. The material shelving system automatically lifts and lowers according to the distance of the A rotating gripper device to avoid collision;

8. When the A rotating gripper device advances to the middle limit position of the B rotating support plate, the C rotating gripper device automatically runs to the right end of the B rotating plate to continue the perfect cutting of the tail material, so as to ensure the overall cutting of the pipe, basically zero tail material.

9. The automatic lifting type material receiving system rises to 15mm from the rotation degree of the pipe, and catches the workpiece while the pipe is cut, so as to prevent the workpiece from falling naturally due to the weight of the pipe, the gap at the cutting point is too large, or it is dropped and deformed.

10. After the automatic lifting type feeding system is finished, it will automatically drop to a fixed position, and at the same time, the feeding box will tilt, and the workpiece will naturally slide down to the ground material collecting hopper.

11. The feeding mechanism is on standby. Before the cutting of the previous pipe is completed, the material preparation is completed, and the operation program of the next pipe processing is carried out on standby.

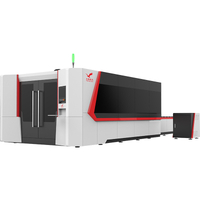

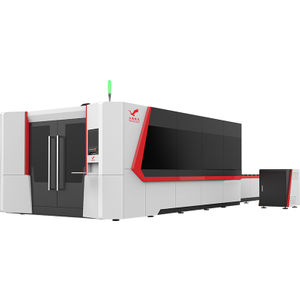

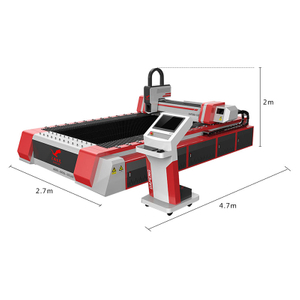

Metal fiber laser cutting machine is used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, grain machinery, textile machinery, construction machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craftsmanship Gifts, tool processing, decoration, advertising, metal external processing, kitchen utensils processing and other manufacturing and processing industries. Stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, galvanized sheet, pickling sheet, copper, titanium and other metal sheet and pipe cutting. Application field of laser cutting machine: It can cut a variety of metal plates and pipes. It is mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, copper plate, aluminum plate, galvanized plate, various alloy plates, rare metals and other materials.

Covered industries: mechanical and electrical equipment, sheet metal processing, chassis cabinets, stainless steel products, kitchen and bathroom, lamps, accessories, auto parts, glasses, hardware tools, advertising signs, decoration and many other industries.

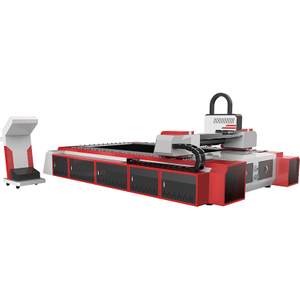

It can realize uncoiling, leveling and cutting of bare coil materials in one go, saving labor and efficient production. Material, transmission, cutting and unloading are all automated, which fully guarantees the high quality, high efficiency and saving of human resources in material processing. The integration of intelligent machinery and people can not only provide flexible and efficient production, but also shorten the production cycle of enterprise orders, making enterprises more competitive in the market.

Features:

1/ It can realize uncoiling, leveling and cutting of bare coil materials in one go, saving labor and efficient production;

2/ Servo motor drive, follow-up roller support, reduce sheet slippage and curling phenomenon;

3/Optimize the traditional processing method and upgrade from a single cutting to an integrated processing production line;

4/ Realize continuous cutting production, improve equipment utilization rate, and create more value for users;

5/After uncoiling the coil, while leveling the sheet by the leveling machine, the stress of the sheet during the leveling process is eliminated, so that the sheet is more flat and a better cutting experience is obtained.