1000W 1500W 2000W HandHeld Fiber Laser Welding Machine Laser Welder with Auto Wire Feeder

How Does Hand-held Laser Welding Work?

Economical laser sources combined with the flexibility of fiber laser delivery provide unprecedented access to hand-held laser welding.

But how does it work? In simple terms, the laser power density melts the metal, eliminating the need to strike an arc; the wobble function eliminates the need to weave the bead manually; and in many cases, wire feed is eliminated completely. The high power density results in a smaller, more controlled weld pool. With precise control of laser parameters, heat distortion effects are reduced, making the process accessible to unskilled operators and allowing organizations to upskill their seasoned employees to more value-added roles.

Equipment reliability was at one time a concern with hand-held laser welding. The building block of the fiber laser is the single-emitter diode, which has a lifetime an order of magnitude longer than the lifetimes of diode array or bar-stack alternatives. The pumps are hermetically sealed to telecom standards and are unaffected by humidity, dust, vibration, and the most aggressive industrial environments.

With hand-held laser welding’s industrial robustness, fiber lasers can be used to complement basic factory automation, further improving efficiency in production. With the relatively recent explosion in collaborative robot technology (cobots), basic levels of factory automation are within reach of many production floors. Cobots are inherently synergistic with hand-held laser welding technology because they are cost effective and simple to use and deploy. The robot’s flexibility combined with the capabilities of hand-held laser welding technology make it suitable for lower-volume, high-product-mix environments. If it can be welded by hand, it likely can be welded with a cobot. This can further improve laser welding productivity by allowing you to preload a part fixture while the cobot performs a weld on a separate fixture.

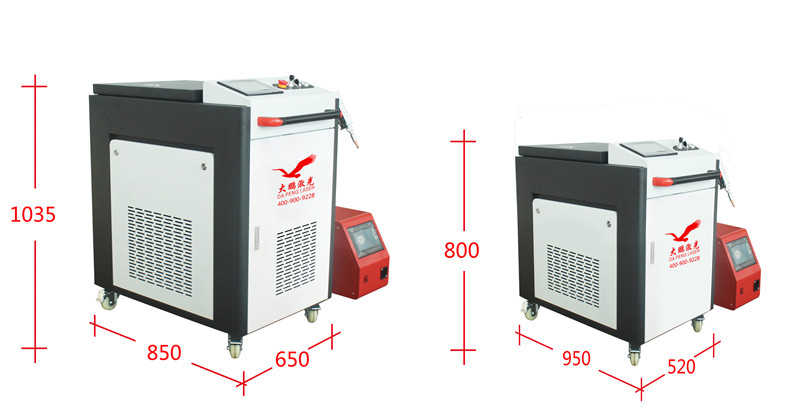

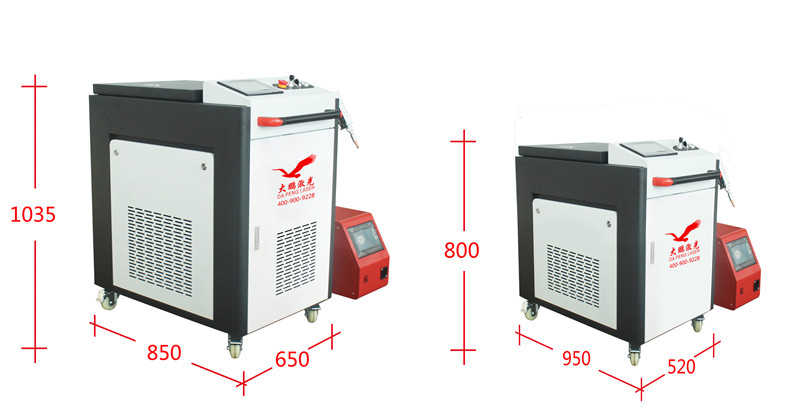

Specification: