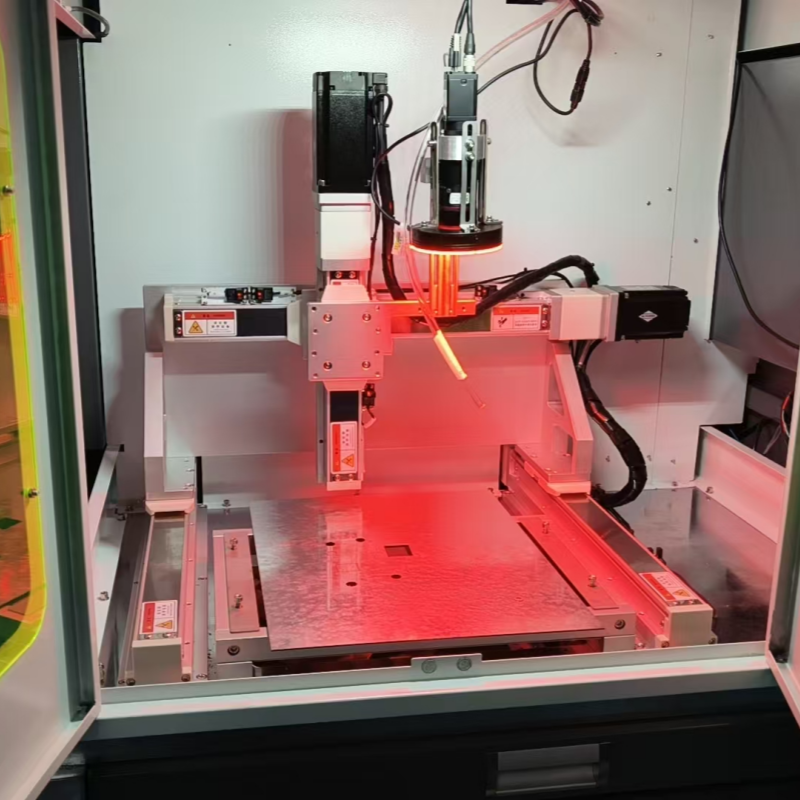

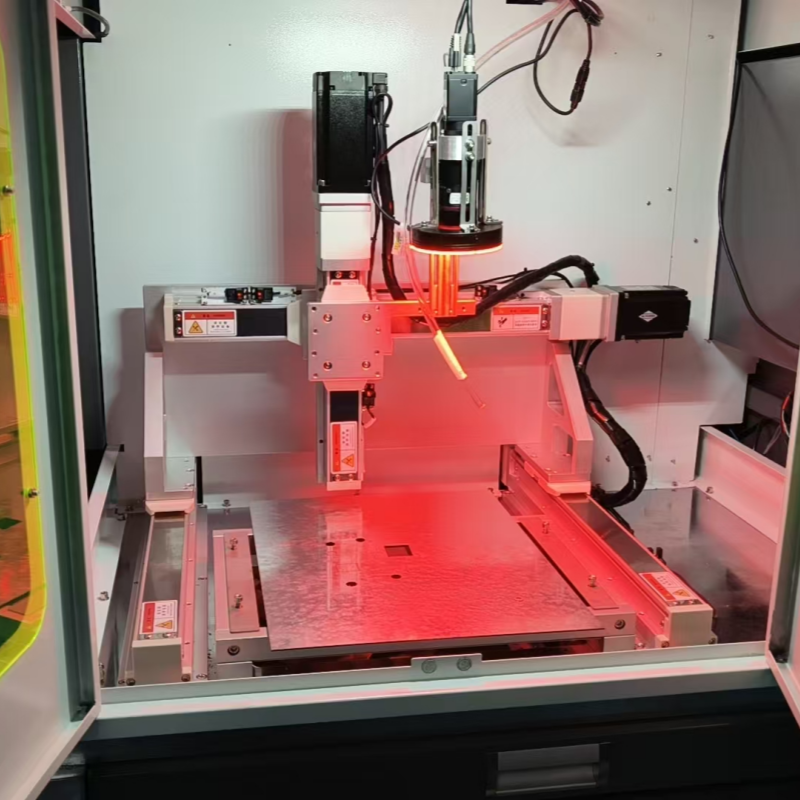

The WK-K59-3020-1000W is a compact, benchtop fiber laser cutting system engineered for ultra-fine processing of sheet metal. It integrates a robust 1000W fiber laser source with a high-rigidity mechanical platform and a precision motion system to deliver exceptional cutting accuracy, smooth edge quality, and remarkable efficiency for thin materials. It is the ideal solution for industries where precision is non-negotiable.

Model Decoding:

WK-K59-3020: Likely the base platform model number.

1000W: Denotes the power of the integrated fiber laser source, defining its cutting capability and speed.

Target Applications & Industries

This machine is designed for high-mix, low-volume production of complex and delicate parts.

Electronics & Telecommunication: Precision components for circuits, shields, connectors, and sensors.

Medical Device Manufacturing: Cutting stents, surgical instrument parts, implant prototypes, and lab device components.

Jewelry & Luxury Goods: Intricate designs and patterns in precious metals.

Research & Development (R&D): Rapid prototyping for new products and technologies.

Precision Engineering: Manufacturing small parts for automotive (e.g., fuel injectors), aerospace (shims, brackets), and consumer electronics.

Key Features & Advantages

Superior Cutting Precision: Achieves micron-level tolerances (±0.02mm repositioning accuracy) and produces clean, burr-free edges, often eliminating the need for secondary finishing.

High Power Density (1000W): The fiber laser provides a high-intensity beam, enabling faster cutting speeds on thin materials and improved energy efficiency compared to CO2 lasers.

Exceptional Stability: The machine's heavy-weight, welded steel frame (220 kg weight) effectively dampens vibrations, ensuring consistent accuracy and smooth operation even at high accelerations.

Intelligent Control System: Features a user-friendly CNC system with a built-in process database for different materials, simplifying operation and ensuring optimal cut quality from the start.

Comprehensive Safety Protections: Includes a full suite of alarms (laser, gas, water, cutting) to protect both the operator and the machine from operational errors or failures.

Compact Footprint: Its relatively small size (950x820x780mm) makes it suitable for laboratory, cleanroom, or workshop environments without requiring extensive floor space.

Detailed Technical Specifications

| Category | Parameter | Details / Value |

| Laser Source | Type & Power | Fiber Laser, 1000W |

| Brand Options | Maxphotonics / Raycus / JPT / Cnlight |

| Processing Range | Working Area (X-Y) | 200 x 300 mm |

| Max. Material Thickness | ~3-4 mm (Mild Steel)

~2-3 mm (Stainless Steel)

~1-2 mm (Aluminum) |

| Z-axis Travel | 100 mm |

| Performance | Positioning Accuracy | ±0.03 mm |

| Repositioning Accuracy | ±0.02 mm |

| Max. Travel Speed | 50 m/min |

| Max. Acceleration | 0.5 G |

| Mechanical System | Guide Rails | HIWIN (Taiwan) |

| Ball Screws | TBI (Taiwan) |

| Servo Motors & Drives | Inovance / Leisai |

| Control System | Controller | Chiaro |

| File Formats | G-code, DXF, DWG, PLT, ENG |

| Key Features | WiFi Control, Process Database, Gas Pressure Alarm |

| Cutting Gases | Types | Air (for carbon steel, economical)

Nitrogen (for stainless steel, clean edges)

Argon (for titanium, oxidation-free) |

| Power Supply | Requirement | 48 KVA / 220 A |

| Physical | Machine Dimensions | 950 (L) x 820 (W) x 780 (H) mm |

| Machine Weight | 220 kg |

| Table Load Capacity | 60 kg |

Why Choose This Machine?

For Precision: It is built specifically for applications where standard laser cutters cannot achieve the required detail or tolerance.

For Quality: The combination of a 1000W fiber laser, high-quality motion components (HIWIN, TBI), and a rigid structure guarantees outstanding and repeatable cut quality.

For Efficiency: It dramatically reduces processing time for small, complex parts compared to traditional mechanical methods like milling or punching.

For Versatility: It can process a wide range of thin metals (carbon steel, stainless steel, aluminum, copper, brass) with quick changeover.

The WK-K59-3020-1000W is more than just a cutter; it is a comprehensive micro-machining solution that empowers manufacturers in high-tech industries to innovate and produce with confidence.