Heavy Slag Removal, Deburring, and Edge Rounding

This machine is designed for processing sheet metal, including stainless steel, carbon steel, aluminum plates, copper plates, and various non-ferrous metals. The equipment is used for:

Heavy Slag Removal: Removing slag formed during processes like cutting, including plasma, laser, and flame cutting.

Deburring: Removing sharp edges and burrs that form during metalworking operations such as punching, shearing, and cutting.

Edge Rounding: Creating smooth, rounded edges (with a controlled radius) to prevent sharp edges that may cause injury or stress concentration points in the metal.

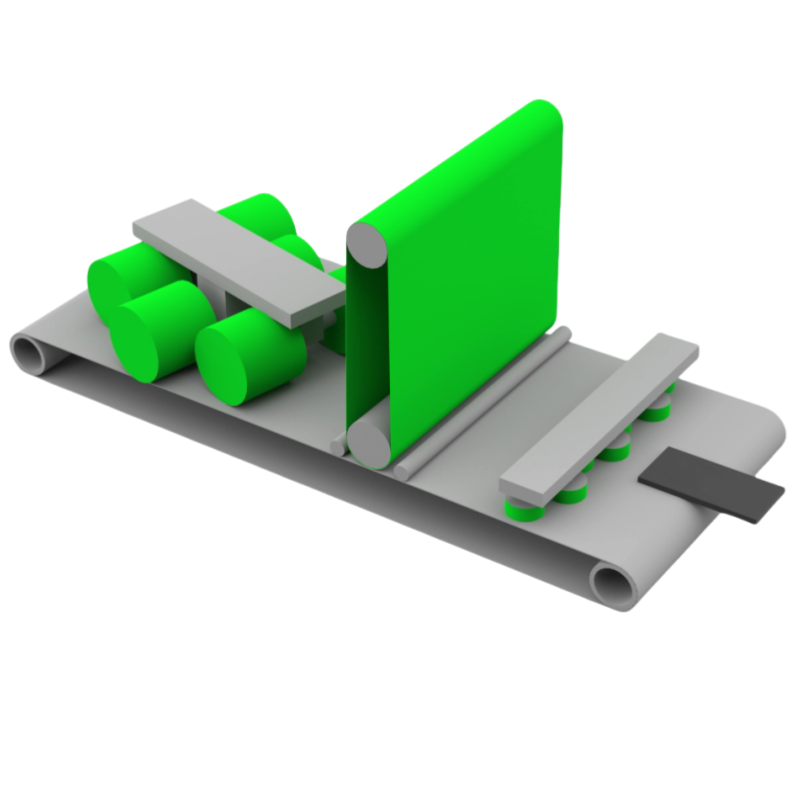

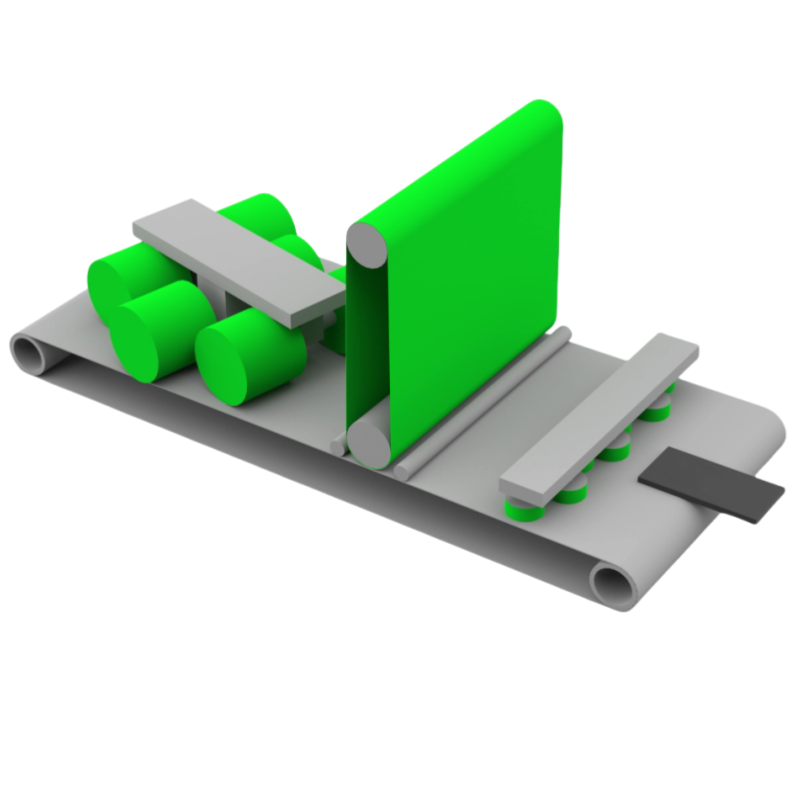

This system consists of three main working stations:

Hammer Disc Brush Station: Used to remove slag particles and burrs from the workpiece by striking the surface.

Sanding Belt Station: Sanding belts are used to remove residual burrs and polish the metal surface.

Multi-Directional Brush Station: The brush station, made up of 6 sets of rotating brushes, performs high-speed centrifugal grinding, polishing, and edge rounding without leaving any dead spots.

These processes work together to ensure the workpiece has uniform edge rounding (R-angle), clean edges and holes, and a flawless finish without affecting the workpiece’s dimensions.

Key Features:

Safety: The equipment is designed to handle heavy-duty slag removal without damaging the workpiece.

Efficiency: Multiple processes (slag removal, deburring, and edge rounding) are integrated into one system for high throughput.

Versatility: The machine is capable of handling complex and customized parts without requiring additional fixtures.

Technical Specifications

| Specification | Details |

| Material | Steel, Aluminum, Stainless Steel |

| Process | Heavy Slag Removal, Deburring, Edge Rounding |

| Min. Part Dimensions (mm) | 50 x 50 |

| Max Material Weight (kg) | 500 |

| Holder System | Magnetic (Vacuum Optional) |

| Processing Width | ≤ 1020 mm |

| Processing Thickness | 1 ~ 80 mm |

| Min. Processing Size | 50 mm x 50 mm (for flat parts, thickness 0.5 ~ 10 mm) |

| Total Power | 50.35 KW |

| Hammer Disc Brush Diameter | Φ162 mm |

| Sanding Belt Dimensions | 1910 mm x 1050 mm |

| Brush Diameter | Φ300 mm x 300 mm |

| Conveyor Feeding Speed | 0.5 ~ 6 m/min (Variable Frequency) |

| Sanding Belt Speed | Approx. 14 m/s |

| Brush Rotation Speed (Self Rotation) | 8 ~ 26 m/s (Variable Frequency) |

| Brush Revolution Speed (Planetary Rotation) | 1 ~ 15 rpm (Variable Frequency) |

| Brush Planetary Axial Head Count | 1 |

| Brush Planetary Self-Rotation Head Count | 6 |

| Thickness Servo Adjustment Precision | 0.01 mm |

| Brush Compensation Servo Adjustment Precision | 0.01 mm |

| Grinding Consumables | Hammer Disc Brush, Sanding Belt, Brushes |

| Dust Collection Airflow | 4000 m³/h |

| Machine Dimensions (L x W x H) | 3600 mm x 2150 mm x 2500 mm |

| Machine Weight | Approx. 4.5 tons |

Operational Details:

Hammer Disc Brush Station: This station uses a rotating hammer disc to remove heavy slag and large burrs from the edges and surface of the workpiece.

Sanding Belt Station: After slag removal, the workpiece is polished and deburred using a high-speed sanding belt that smooths the surface.

Multi-Directional Brush Station: This station features six multi-directional rotating brushes that provide 360-degree coverage to ensure uniform burr removal and edge rounding. This ensures consistent radii and smoothness on the workpiece edges, especially for complex shapes and parts.

The system’s vacuum conveyor holds the workpiece securely during processing, ensuring precise results without the need for specialized tooling. Additionally, wet dust collection is used to keep the workspace clean and safe by collecting grinding dust and recycling metal powder.