1000mm Edge Rounding Machine for Deburring and Edge Rounding of Metal Plates

Introduction:The Edge Rounding Machine is designed to round the sharp edges of metal plates, ensuring enhanced safety during the post-processing phase. This machine is essential in industries where metal parts are used and the edges need to be smoothed for safe handling. The equipment can process a variety of materials, including steel, aluminum, and stainless steel, with high precision and efficiency. The primary application of this machine is edge rounding, which reduces the risk of injury caused by sharp metal edges, ensuring a safer working environment.

Key Features:

Suitable for steel, aluminum, and stainless steel.

Efficient edge rounding process for metal plates.

Improves occupational safety by smoothing sharp edges.

Can handle materials with a thickness range of 0.5mm to 80mm.

Capable of processing materials with a maximum width of 1000mm.

Variable conveyor speed for customizable processing speed (0.5-6.0 m/min).

Magnetic holder system (optional vacuum system).

Compact and robust design with low power consumption.

Technical Specifications

| Feature | Specification |

| Material | Steel, Aluminum, Stainless |

| Process | Edge Rounding |

| Material Thickness (mm) | 0.5 - 80 |

| Max Material Width (mm) | 1000 |

| Min Part Dimensions (mm) | 50 x 50 |

| Max Material Weight (kg) | 500 |

| Conveyor Speed (m/min) | 0.5 - 6.0 |

| Min Deduster Need (m³/h) | 3500 |

| Machine Power Consumption (kW) | 27.2 |

| Machine Weight (kg) | 200 |

| Holder System | Magnetic (Vacuum Optional) |

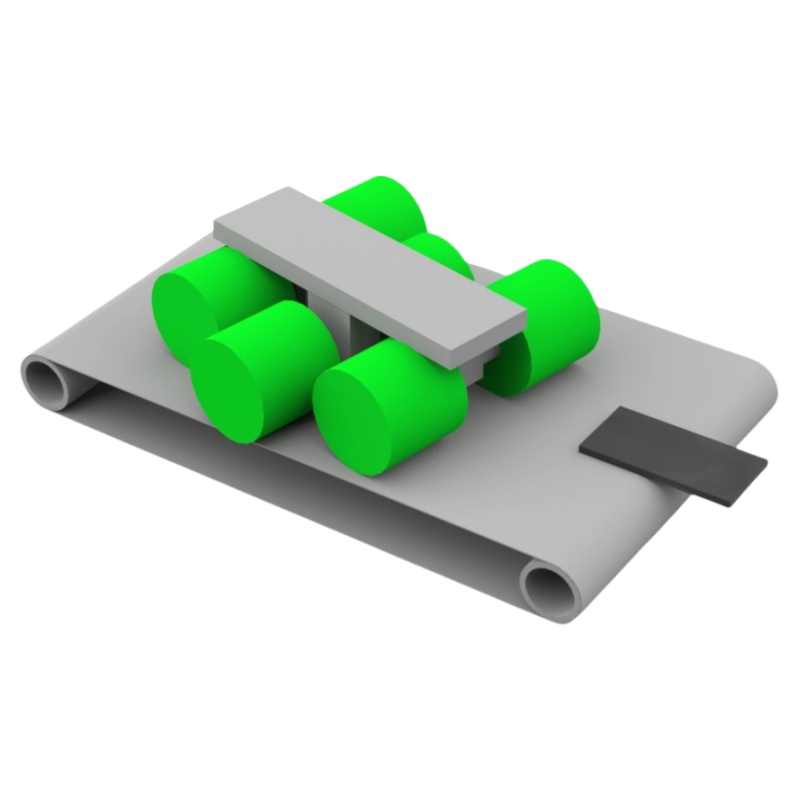

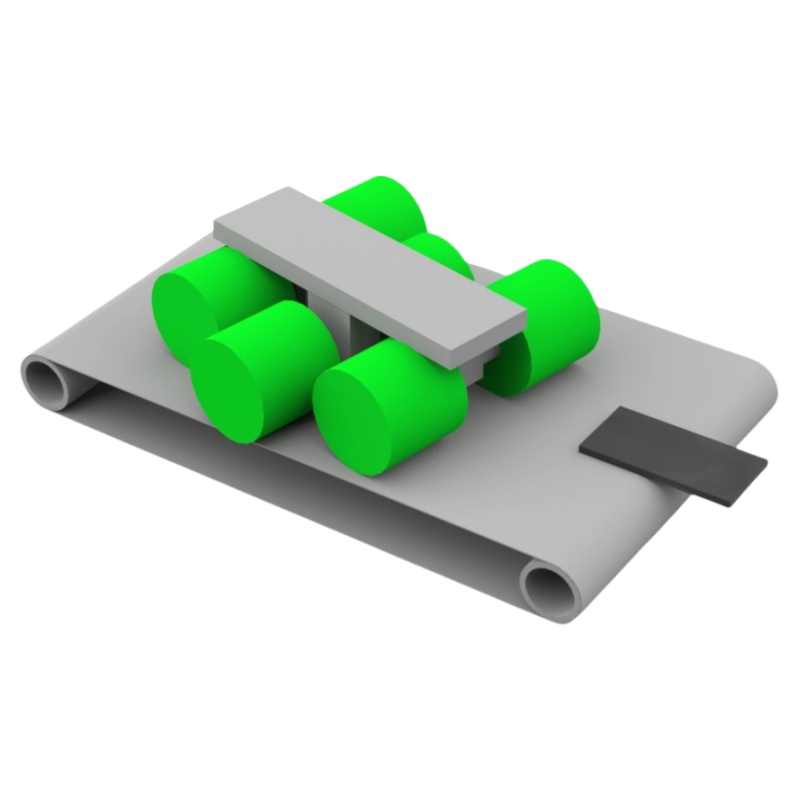

| Flap Wheels Quantity | 6 |

| Flap Wheel Dimensions | Ø300 x 300 mm |

| Conveyor Width | 1000 mm |

| Working Height | 80 mm |

| Model | MSP-M1000 |

| Processes | Edge Rounding |

Flap Wheel Dimensions:

Diameter: Ø300 mm

Length: 300 mm