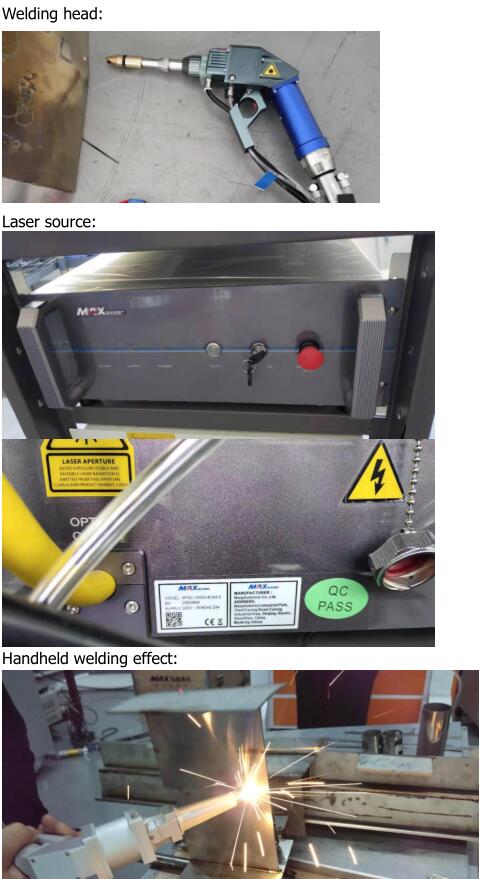

Fiber optical transmission laser welding machine is a laser welding equipment which couples the high energy laser beams into the optical fiber, after long-distance transmission, then transformed into parallel lights through collimating mirror to be focused on the work piece to implement the welding. The welding methods include vertical welding, paraller welding, stitch welding and so on.

Advantages

1,High efficiency

Speed is faster than the traditional welding speed by more than two times.

2,High quality

Smooth and beautiful welding seam,without subsequent grinding, saving time and cost.

3,Low cost

80% to 90% power savings, processing costs are reduced by 30%.

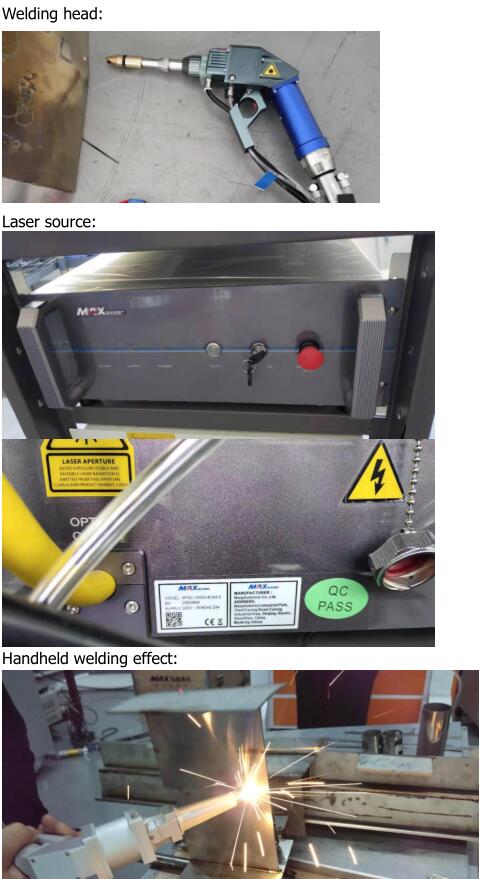

4,Flexible operation

Easy operation,no need experience can do a good job.

Application Materials

Laser welding can be used in welding stainless steel, aluminum, copper, gold, silver, chromium, nickel, titanium and other metals or alloys, can also be used for a variety of welding between different materials, such as: copper - brass, titanium - gold, Titanium - molybdenum, nickel - copper and so on.

Handheld laser welding machine in customer workshop https://youtu.be/cGhemuw8Pe8