Working Width: 1300mm

Wet Grinding System: Utilizes a water spray to cool the workpiece, minimize dust, and extend the lifespan of consumables such as belts and polishing wheels.

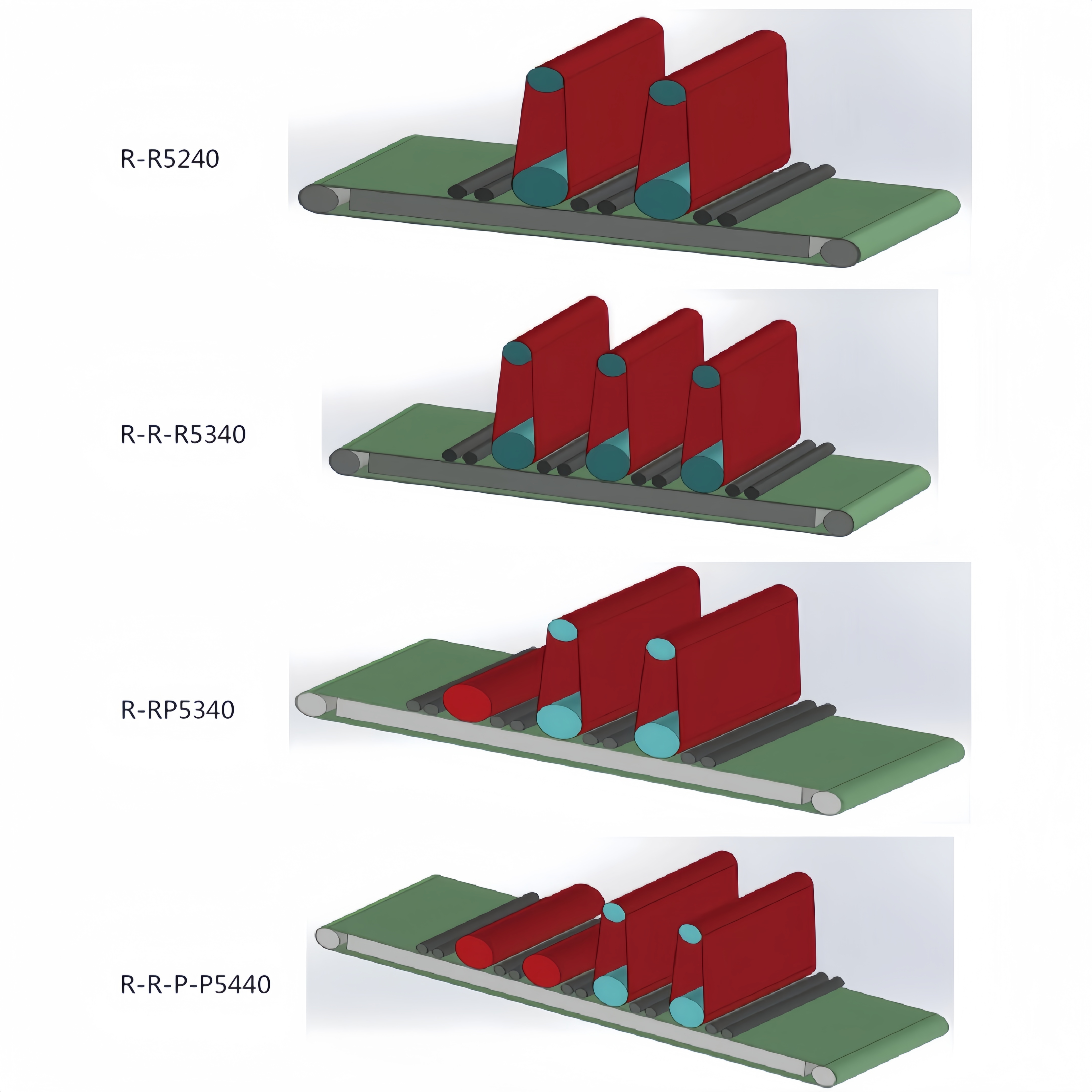

4 Belt Stations: These allow for multi-stage grinding and deburring processes:

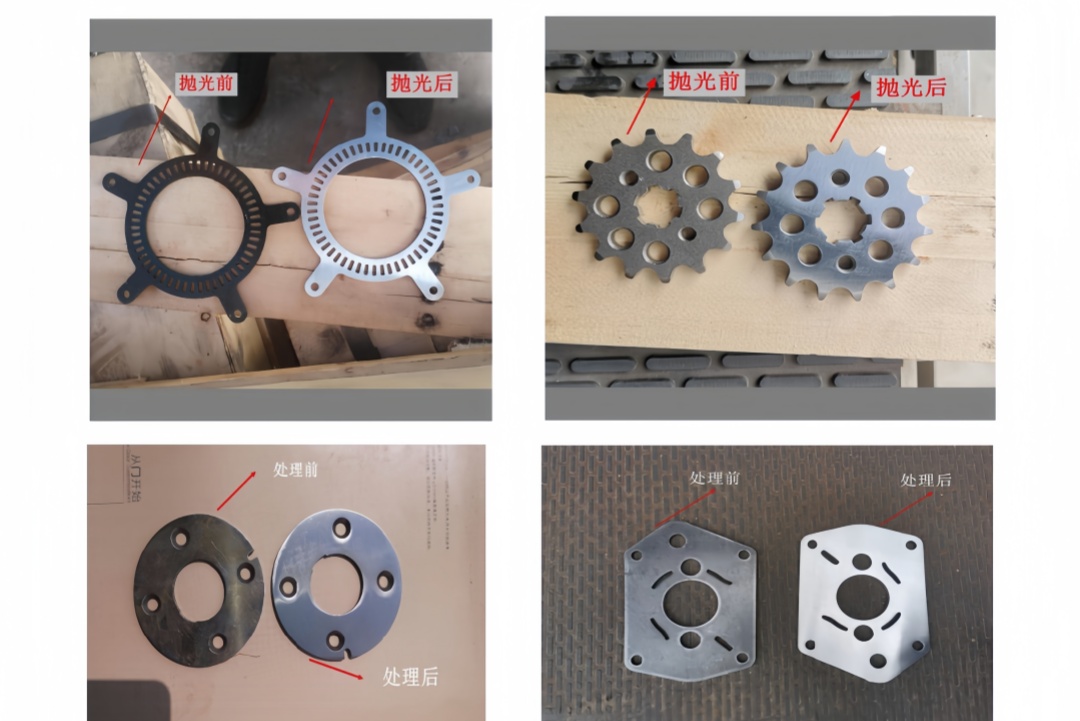

1 Polishing Wheel: The final polishing wheel is designed for achieving a consistent, smooth finish on the metal surface, enhancing aesthetics and corrosion resistance.

Conveyor System: The machine includes a heavy-duty conveyor belt to handle continuous feeding of metal sheets, improving productivity.

Adjustable Feed Speed: To optimize the processing of different materials, the conveyor speed can be adjusted according to the requirements of each metal type or finish.

Water Cooling and Filtration: The machine operates in wet conditions to prevent overheating and ensure uniform material removal. The system comes equipped with a water filtration system to remove debris.

Deburring, Edge Rounding, and Finishing: Capable of removing sharp edges, burrs from laser cutting, punching, and other processes, while rounding the edges to an R-angle.

Versatile Material Handling: Suitable for stainless steel, carbon steel, aluminum, and other non-ferrous metals.

Dust and Slurry Collection: An integrated slurry collection system handles waste material and water efficiently.