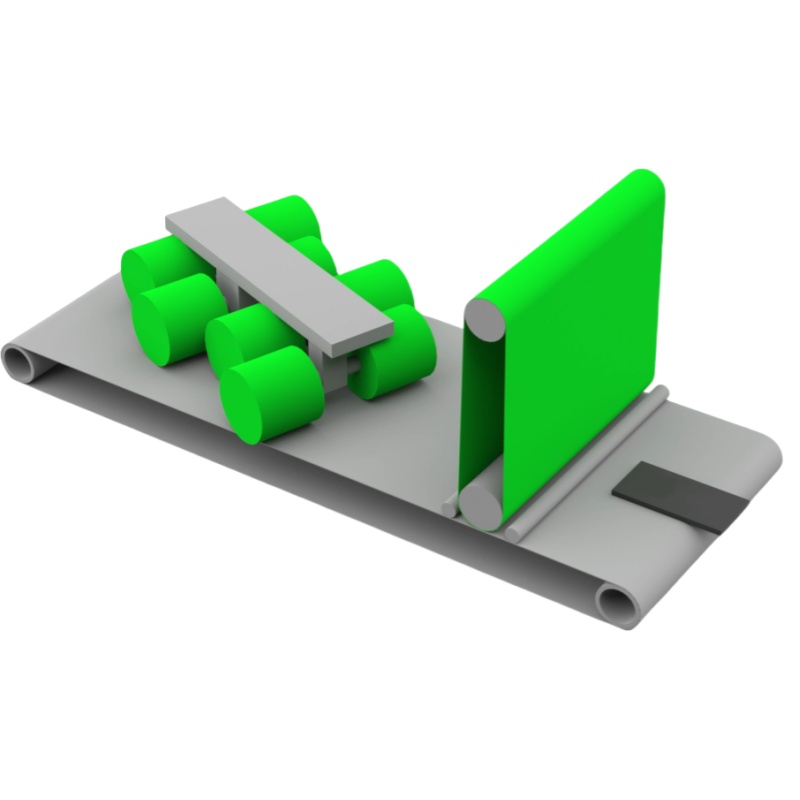

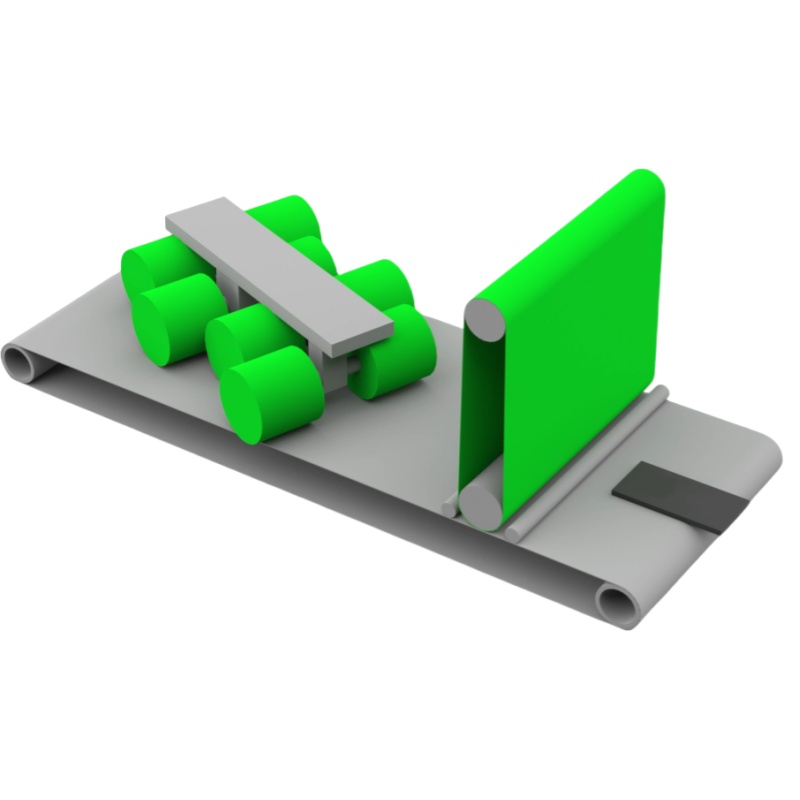

1350mm Metal Edge Deburring Machine for Deburring, Edge Rounding, Finishing, and Laser Oxide Removal (Rotary Brush Head & Abrasive Belt Unit with Contact Drum)

The 1350mm Metal Edge Deburring Machine is designed for a comprehensive range of metal surface treatments, including deburring, edge rounding, finishing, and laser oxide removal. This advanced machine features a rotary brush head system for uniform 360° edge rounding and an abrasive belt unit with contact drum for precise finishing and oxide removal. It is perfect for industries requiring high-quality metal processing, such as aerospace, automotive manufacturing, and general fabrication.

Key Features:

Rotary Brush Head System:

The machine utilizes eight counter-rotating brushes arranged on a single head. The head moves around a vertical axis while oscillating across the workpiece, ensuring 360° processing from all angles. This innovative system provides uniform edge rounding up to a radius of 1.5 mm, creating smooth, precise edges on metal parts.

Abrasive Belt Unit with Contact Drum:

The abrasive belt unit equipped with a contact drum provides high-precision finishing. The abrasive belt is ideal for removing sharp edges, contouring parts, and achieving uniform surface finishing. This unit works in conjunction with the rotary brush system for efficient oxide skin removal, improving the final surface quality and providing a clean, polished finish.

Dual Brush Types for Versatile Processing:

Adjustable Brush Height and RPM:

Even Brush Wear:

Flexible and Wide Application Range:

This machine is highly adaptable, making it suitable for processing various materials such as stainless steel, carbon steel, aluminum, and copper. It is especially effective in metal fabrication, welding, laser cutting, plasma cutting, and flame cutting industries.

High-Performance Deburring and Finishing:

The combination of rotary brushes and abrasive belts guarantees high-quality deburring, edge rounding, and oxide removal, ensuring metal parts are prepared with smooth, polished, and clean edges for further processing or use in assembly.

Applications:

Deburring of metal parts cut by laser, plasma, or flame cutting methods.

Edge rounding to remove sharp edges and create rounded profiles up to 1.5 mm radius.

Finishing metal surfaces for a smooth, polished appearance.

Laser oxide removal for clean surfaces free of heat discoloration.

Benefits:

Uniform 360° Processing: Ensures even edge rounding and oxide removal from all angles.

Dual Brush and Abrasive Belt System: Maximizes processing efficiency and reduces operational steps.

Customizable Settings: Adjustable brush height and RPM allow for flexibility in metal processing.

Wide Material Compatibility: Suitable for various materials, including stainless steel, aluminum, and copper.

Extended Consumable Life: Even brush wear and efficient abrasive belt use minimize downtime and consumable costs.