200W Air-Cooled Pulsed Laser Cleaning Machine Series

Portable Handheld Laser Cleaner for Injection Mold Cleaning & Residue Removal

Product Overview

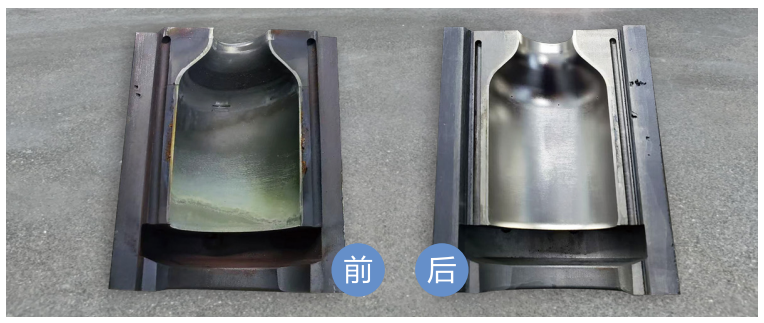

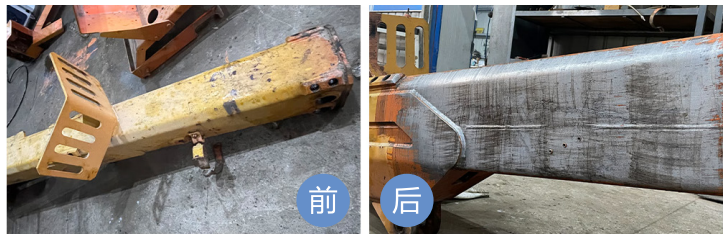

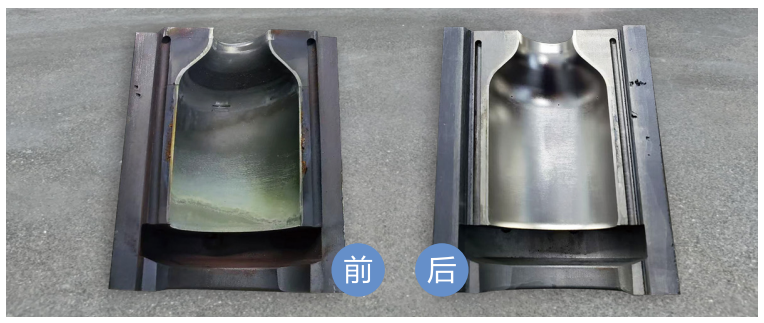

The 200W Air-Cooled Pulsed Laser Cleaning Machine Series is a compact and efficient portable handheld laser cleaning system specifically designed for injection mold cleaning and residue removal.

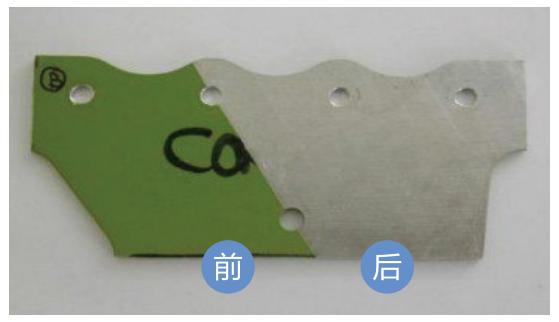

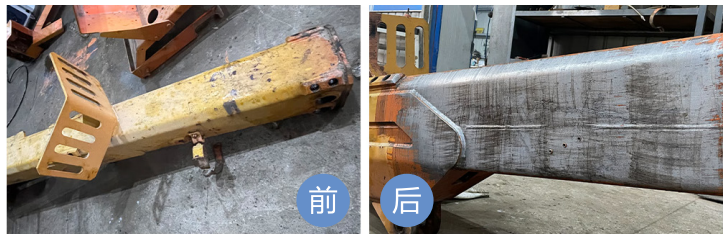

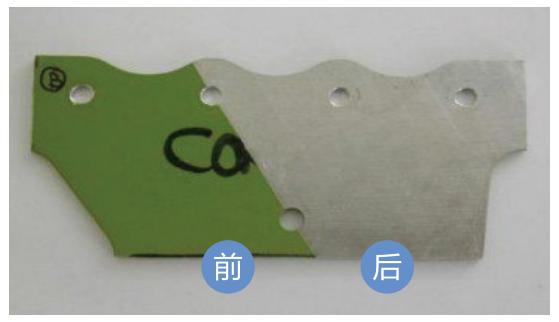

It effectively removes plastic residues, burnt deposits, oil, grease, carbonized layers, oxidation films, and release agent residues from mold surfaces without causing mechanical wear or surface damage.

With an air-cooled structure, the machine operates without a water chiller, offering high mobility, low maintenance, and stable performance, making it ideal for daily mold maintenance in injection molding workshops.

Working Principle

This system uses a pulsed fiber laser (1064 nm wavelength).

Laser energy is selectively absorbed by contaminants such as plastic residue and carbon deposits, causing them to vaporize or detach instantly through thermal shock and micro-explosion effects.

The mold substrate reflects most of the laser energy, ensuring non-contact, non-abrasive, and non-destructive cleaning.

Key Features & Advantages

✔ Designed for Injection Mold Cleaning

Removes plastic residue and burnt material

Cleans oil, grease, and release agent buildup

Eliminates oxidation layers and discoloration

✔ Non-Damaging to Mold Surface

No abrasion, grinding, or polishing

Preserves mold cavity precision and texture

Extends mold service life

✔ Portable & Air-Cooled Design

No external water chiller required

Compact size, easy to move and operate

Suitable for on-line and off-line mold cleaning

✔ Environmentally Friendly

✔ Easy Operation

Handheld laser gun with ergonomic design

Multiple preset cleaning modes

Adjustable laser parameters for different mold materials

Typical Technical Specifications (200W Model)

| Item | Specification |

| Laser Type | Pulsed Fiber Laser |

| Laser Power | 200 W |

| Laser Wavelength | 1064 nm |

| Cooling Method | Air Cooling |

| Laser Class | Class 4 |

| Cleaning Modes | 6 Modes |

| Max. Scanning Width | 100 mm |

| Optical Fiber Length | 5 m |

| Power Supply | AC 220V, 50 / 60 Hz |

| Input Power | 1000 W |

| Operation Mode | Handheld / Portable |

Application Areas

The 200W air-cooled pulsed laser cleaner is widely used for:

Injection molds for plastic parts

Automotive interior plastic molds

Home appliance plastic molds

Medical plastic molds

Electronics and precision plastic molds

It is especially suitable for mold cleaning without disassembly, reducing downtime and improving production efficiency.

Suitable Mold Materials

Safety & Reliability

Stable pulsed laser output

Long laser source lifespan (up to 100,000 hours)

Laser safety goggles required during operation

User-friendly control system with parameter memory

Conclusion

The 200W Air-Cooled Pulsed Laser Cleaning Machine Series provides a safe, efficient, and eco-friendly solution for injection mold cleaning and residue removal.

Compared with traditional chemical or mechanical cleaning methods, it offers higher precision, lower maintenance cost, and longer mold life, making it an ideal choice for modern injection molding production lines.