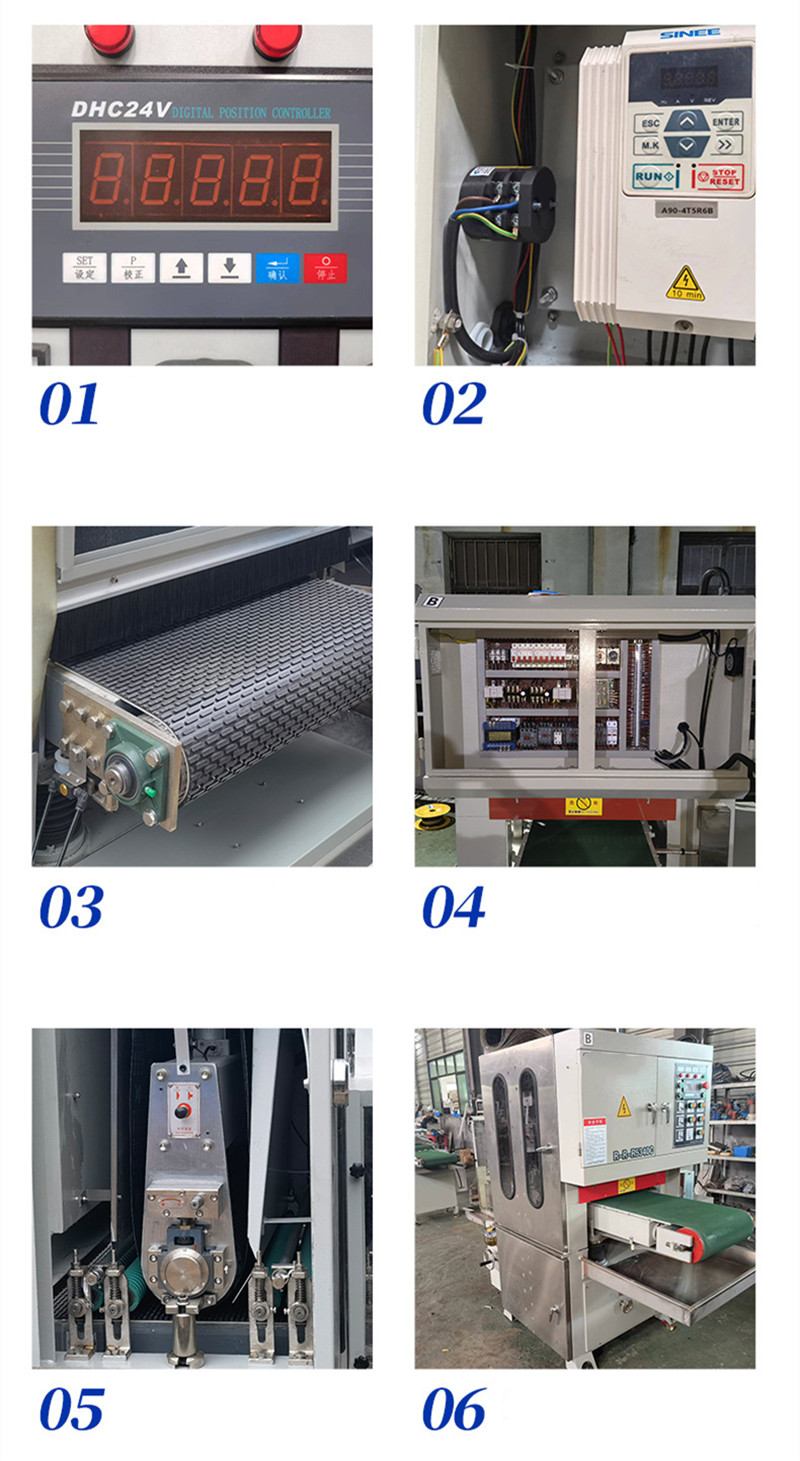

400mm Wide Belt Sander (With Magnetic Table)

The 400mm wide belt sander is an efficient machine specifically designed for metalworking. Featuring a magnetic worktable, it securely holds workpieces in place during processing. This sander is particularly suitable for fine sanding, deburring, and polishing of metal surfaces.

Key Features

Wide Belt Design: The 400mm width allows for processing various sizes of metal workpieces, providing higher machining efficiency.

Magnetic Worktable: The magnetic table firmly holds ferromagnetic materials (such as carbon steel and stainless steel), ensuring that the workpieces do not shift during processing, which enhances precision and safety.

Versatility: Capable of performing deburring, sanding, polishing, and oxide skin removal, it is suitable for post-processing of laser-cut parts, stamped components, and more.

Water Cooling System: Equipped with a water cooling system that effectively reduces belt temperature, prevents workpiece deformation, and extends belt life.

Automatic Feeding System: Facilitates continuous processing, increasing production efficiency, particularly for high-volume production.

Metal wet sanding machines:

| Parameter | Units | R5240 | RR5240 | RP5240 | RRR5340 | RRP5340 | RRRP5440 |

| Maximum Width | mm | 400 | 400 | 400 | 400 | 400 | 400 |

| Maximum Height | mm | 60 | 60 | 60 | 60 | 60 | 60 |

| Minimum Length | mm | 150 | 150 | 150 | 150 | 150 | 150 |

| First Belt Power | kW | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Second Belt Power | kW | / | 5.5 | / | 5.5 | 5.5 | 5.5 |

| Third Belt Power | kW | / | / | / | 5.5 | / | 5.5 |

| Polishing Wheel Power | kW | / | / | / | / | 5.5 | 5.5 |

| Rotating Motor Power | kW | / | / | / | / | / | / |

| Feeding Power | kW | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Power Up/Down | kW | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 |

| Swing Motor Power | kW | / | / | 1.5 | / | 1.5 | 1.5 |

| Vacuum Motor Power | kW | / | / | / | / | / | / |

| Dimensions | m | 1.8 x 1.5 x 1.8 | 2.1 x 1.5 x 1.8 | 2.1 x 1.5 x 1.8 | 2.4 x 1.5 x 1.8 | 2.4 x 1.5 x 1.8 | 2.7 x 1.5 x 1.8 |

| Weight | kg | 1000 | 1200 | 1200 | 1500 | 1500 | 1800 |

| Belt Size | mm | 1520 x 400 | 1520 x 400 | 1520 x 400 | 1520 x 400 | 1520 x 400 | 1520 x 400 |

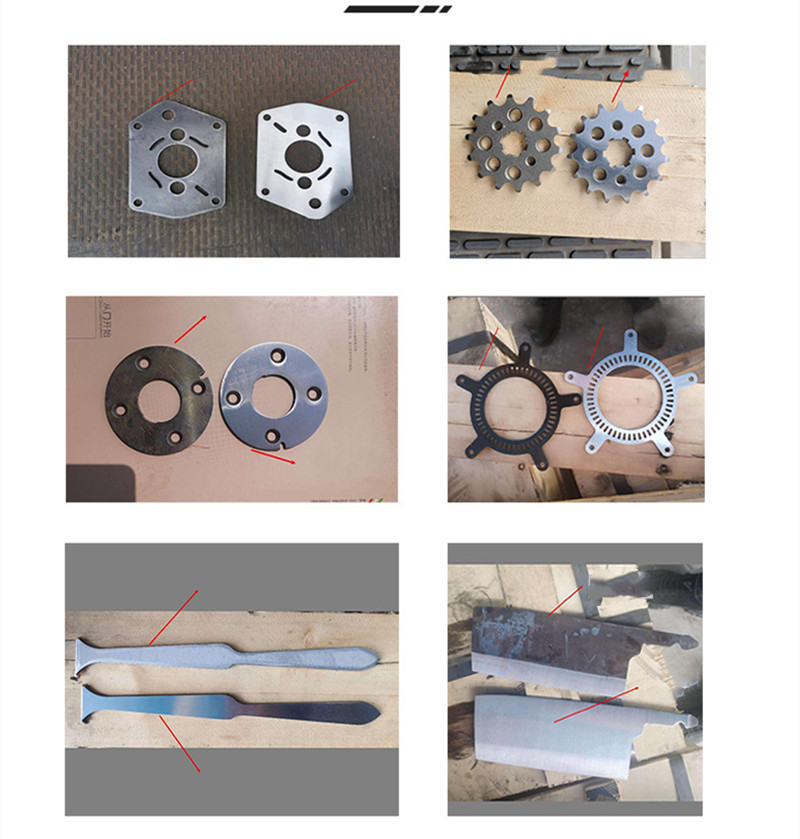

Applications

Metalworking Industry: Suitable for surface treatment of various metals such as steel, aluminum, and copper.

Automotive Manufacturing: Used for surface sanding and polishing of car bodies and components.

Machinery Manufacturing: For precision processing and surface treatment of machine parts.

Home Appliance Industry: For deburring and polishing metal components in appliances.

Advantages

High Efficiency: The magnetic worktable ensures stability during processing, improving overall efficiency.

Precision: Reduces processing errors caused by workpiece movement, ensuring high-quality results.

Strong Adaptability: Capable of handling a variety of metal materials, flexibly meeting different production needs.

Conclusion

The 400mm wide belt sander (with magnetic table) is an ideal metalworking machine that combines efficiency, precision, and versatility. It is well-suited for a range of industrial applications and significantly enhances both the efficiency and quality of metal processing, making it an essential tool in modern metal manufacturing and processing industries.

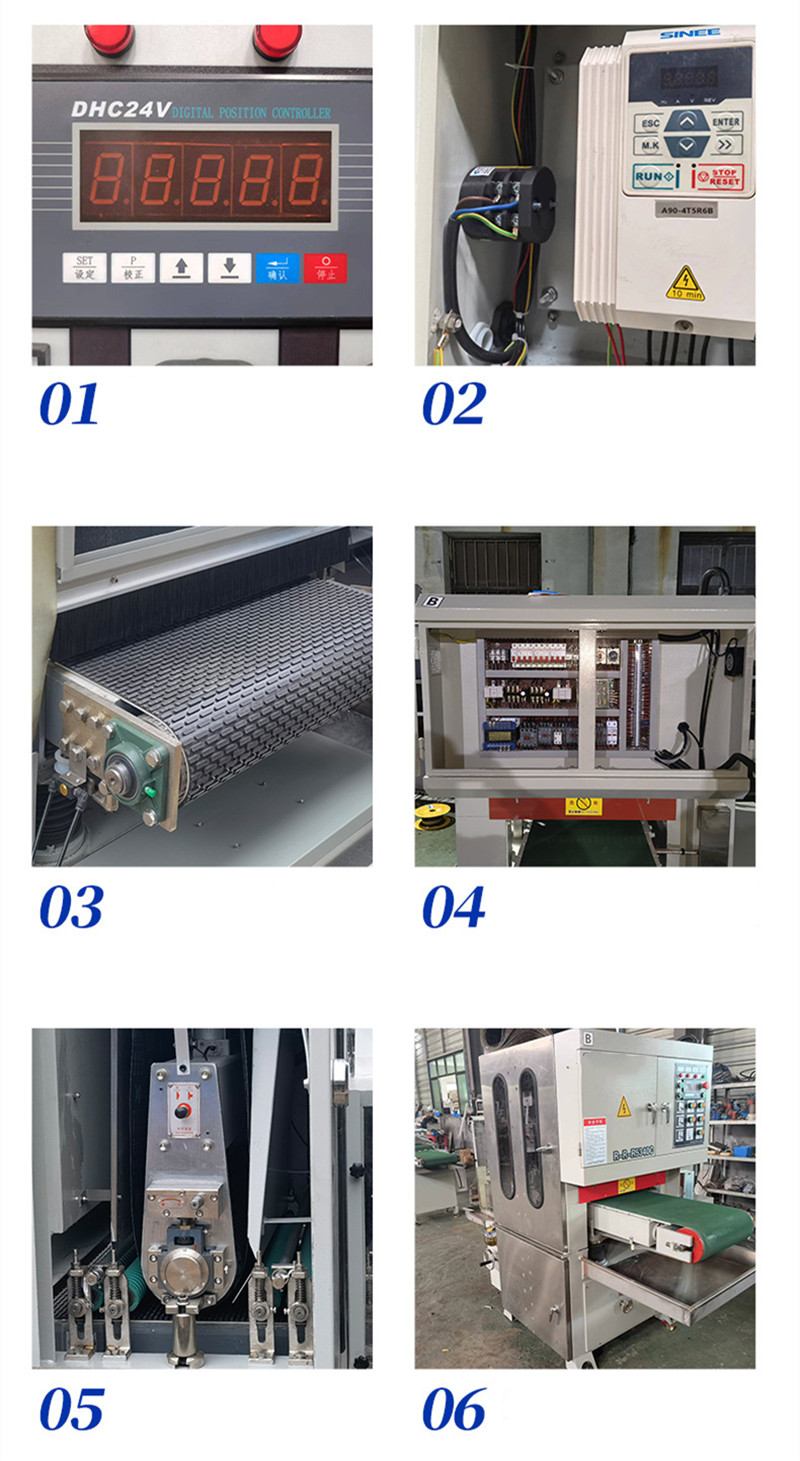

Magnetic Table or Non-Magnetic Table Conveyor Belt Wet Sanding Machine

A conveyor belt wet sanding machine with a magnetic or non-magnetic worktable is suitable for continuous processing of large batches of metal workpieces, especially for surface finishing, deburring, polishing, and oxide removal. These machines use a conveyor belt system to transport the workpieces to the sanding area, and depending on the material, they use either a magnetic or non-magnetic worktable to secure the workpieces, ensuring stability and safety during processing.

Magnetic Table Conveyor Belt Wet Sanding Machine

This type of machine is specifically designed for processing ferromagnetic materials such as carbon steel and stainless steel. The magnetic worktable holds the workpieces firmly on the conveyor belt through magnetic force, making it ideal for thin or lightweight workpieces that may move during processing.

Features:

Magnetic Fixing and Conveying: The magnetic table secures the ferromagnetic workpieces on the conveyor belt through magnetic force, ensuring they remain stationary during continuous processing.

High Efficiency: The conveyor belt system supports automated processing, suitable for mass production, greatly improving work efficiency.

Application Range: Ideal for thin sheets, stamped parts, laser-cut parts, and other ferromagnetic materials requiring deburring, grinding, and surface treatment.

Water Cooling and Dust Control: The water cooling system effectively reduces the temperature during grinding, preventing workpiece deformation, while also reducing dust and ensuring environmental safety.

Advantages:

Continuous Processing: Suitable for large-scale automated production, reducing manual intervention and increasing efficiency.

Excellent Stability: Magnetic fixing prevents the workpieces from shifting during processing, ensuring precision.

Heat Dissipation: The water cooling system efficiently dissipates heat, extending the lifespan of the sanding belts.

Disadvantages:

Limited Material Compatibility: Only applicable to ferromagnetic materials like steel and stainless steel, unsuitable for non-magnetic materials.

Fixing Limitation: For thicker or more complex-shaped workpieces, the magnetic force may not be strong enough for adequate securing.

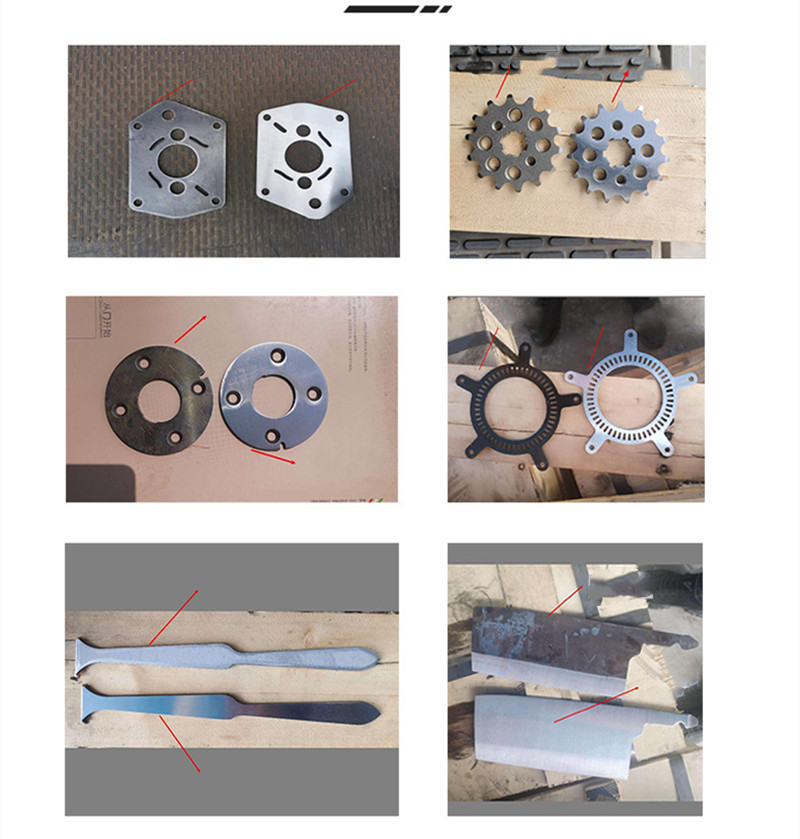

Non-Magnetic Table Conveyor Belt Wet Sanding Machine

The non-magnetic worktable version is suitable for processing non-ferromagnetic materials such as aluminum, copper, and brass, as well as ferromagnetic materials. These machines typically use vacuum suction or mechanical clamps to secure the workpieces on the conveyor belt, allowing for efficient grinding, polishing, and deburring.

Features:

Flexible Fixing Methods: Non-magnetic worktables usually utilize vacuum suction or mechanical clamps to hold workpieces, making them suitable for processing a wide variety of materials and workpiece shapes.

Wide Material Compatibility: Can handle both ferromagnetic and non-ferromagnetic materials, including aluminum, copper, titanium, and composites.

Continuous Production: The conveyor belt ensures continuous automated processing, ideal for large-scale production lines.

Water Cooling and Dust Management: The wet sanding process reduces dust generation and prevents overheating, extending the life of sanding belts.

Advantages:

Versatility: Suitable for both ferromagnetic and non-ferromagnetic materials, ideal for a wide range of workpieces and shapes.

Continuous Production Mode: The automated conveyor system increases production efficiency, ideal for high-volume batch processing.

Flexible Fixing: Suitable for complex-shaped workpieces, offering a wide range of material processing.

Disadvantages:

More Complex Fixing: Vacuum suction may not work well for very small or porous workpieces, requiring additional clamps.

Higher Cost: Vacuum suction or mechanical clamps increase the complexity and cost of the equipment compared to magnetic worktables.

Comparison of Application Scenarios:

Magnetic Table is suitable for:

Ferromagnetic materials, such as steel and stainless steel.

Processing thin sheets and lightweight parts that need stable fixation.

Non-Magnetic Table is suitable for:

Non-ferromagnetic materials, such as aluminum, copper, and brass.

Complex-shaped workpieces or those that cannot be secured by magnetic force.