Basic parameters of magnetic metal sanding machine equipment:

1. Scope of equipment application: Suitable for flat plate parts, carbon steel plates, stainless steel plates, aluminum plates, copper plates, titanium alloys, various non-ferrous metals, rubber and plastic materials, marble, etc.

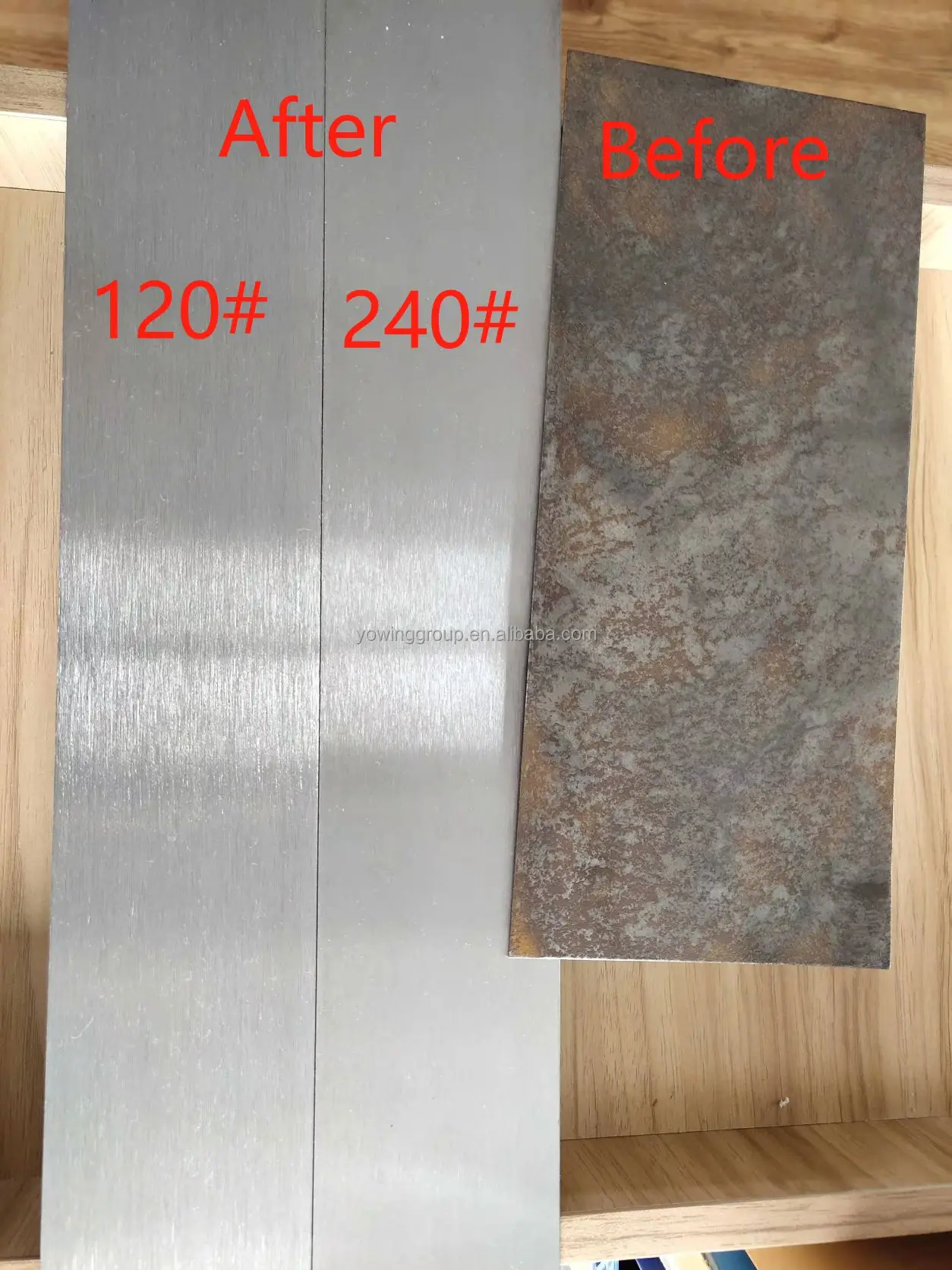

2. Equipment function: Suitable for surface drawing, polishing, scratch removal, longitudinal burr removal, oxide skin removal, roughening, thickness setting and other processing of various flat board parts.

3. Equipment combination: Sandbelt+polishing wheel single or multiple combination structures

4. Equipment processing width: 350mm, 650mm, 800mm, 1050mm, 1350mm, 1600mm, 2000mm, 2200mm

5. Equipment processing thickness: 1-80mm

6. Linear speed of sand belt: 18m/s (optional variable frequency speed regulation)

7. Polishing wheel linear speed: 20m/s (optional variable frequency speed regulation)

8. Conveying and feeding speed: 2-11m/min (variable frequency adjustable)

9. Optional feeding method:

(1) Conveyor belt+rubber pressure roller for clamping and feeding (suitable for ordinary workpieces. Workpiece length ≥ 280mm)

(2) Strong permanent magnet adsorption conveying and feeding (suitable for carbon steel workpieces. Workpiece size ≥ 10mm × 10mm)

(3) Vacuum negative pressure adsorption conveying and feeding (suitable for stainless steel plates, copper plates, aluminum plates, etc. that are not magnetically adsorbed. Workpiece size ≥ 50mm × 50mm)

(4) Rubber roller+rubber roller clamp feeding (suitable for large and heavy workpieces. Workpiece length: ≥ 280mm)

10. Four column synchronous lifting, digital setting and reading of lifting height, unit: mm

11. Each workstation of the equipment is equipped with spray water pipes at the front and back to provide grinding fluid. Water blocking rollers are installed at the inlet and outlet to prevent splashing of the grinding fluid. Upper and lower air knives are installed at the outlet to cut and dry the water, and three sets of water squeezing rollers are equipped to squeeze the water.

12. Equipped with an automatic paper belt filter to filter grinding dust and provide grinding circulating grinding fluid, achieving environmentally friendly production.

13. Advantages of wet processing:

(1) Wet machining workpieces are less prone to thermal deformation during cold machining;

(2) The surface roughness of wet processed workpieces is better;

(3) Wet machining absorbs all grinding dust, resulting in a better working environment;

(4) Wet processing consumables have a longer service life.