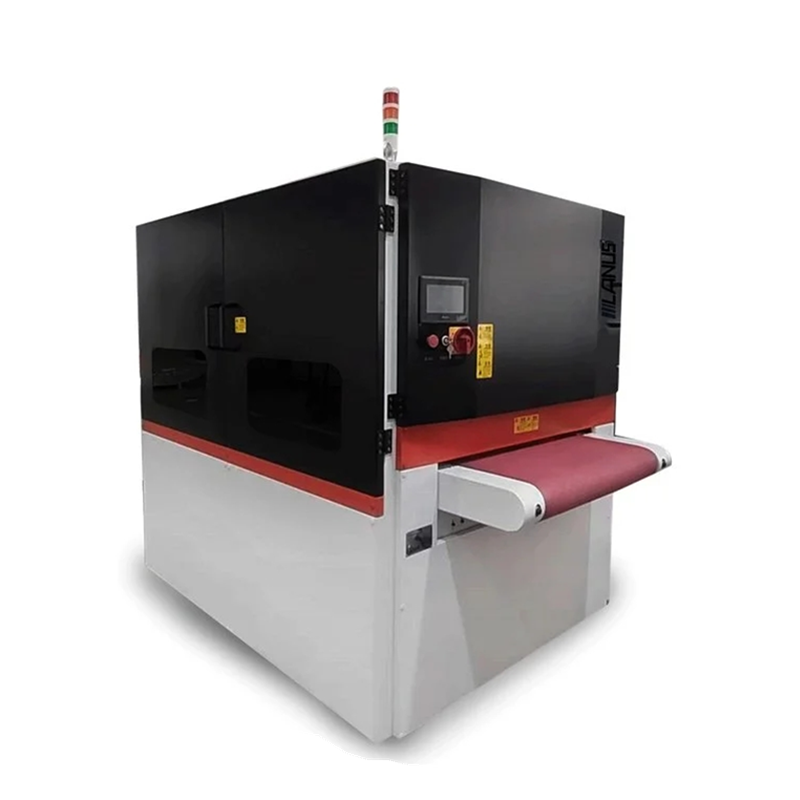

450mm Metal Deburring Machine

Precision Deburring, Edge Rounding & Surface Finishing for Sheet Metal Parts

The 450mm metal deburring machine is engineered for high-efficiency surface finishing of small to mid-sized metal parts. With a working width of 450mm, this compact machine is perfect for processing laser-cut, punched, or sheared sheet metal, removing burrs, smoothing sharp edges, and achieving a consistent surface finish.

It’s suitable for a wide range of materials, including carbon steel, stainless steel, aluminum, copper, and non-ferrous metals.

⚙️ Key Features

Working Width: 450mm

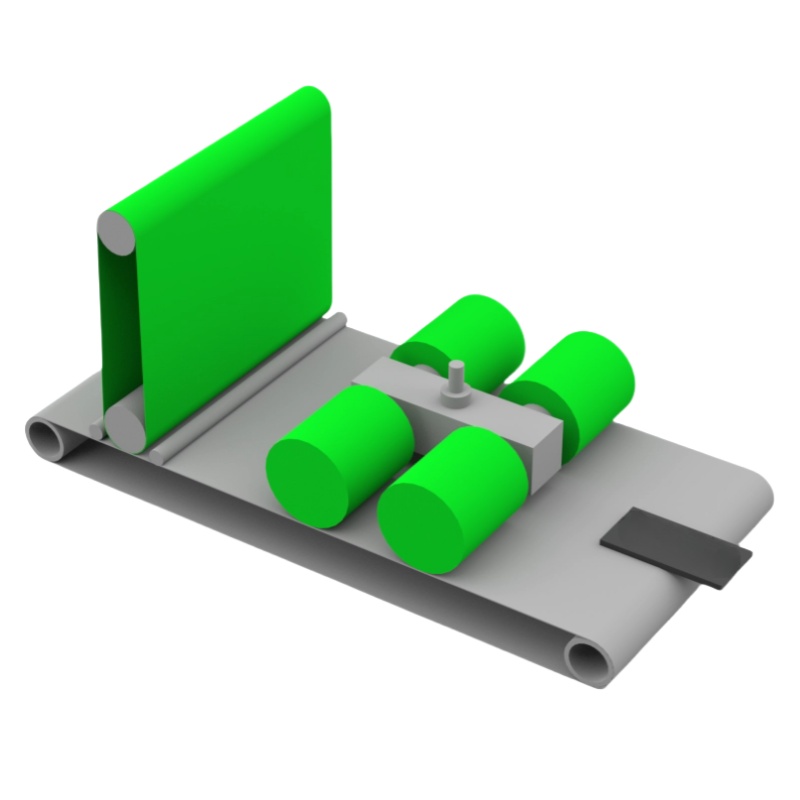

Deburring & Edge Rounding

Efficiently removes sharp edges, burrs, and slag

Creates smooth, uniform rounded edges for safety and quality

Optional Finishing Brushes

⚙️ Material Versatility

Suitable for:

Carbon steel

Stainless steel

Aluminum

Brass/copper

Non-ferrous alloys

⚡ Consistent Results

Uniform deburring and finishing across the full surface

Adjustable pressure, speed, and working parameters

Dust Collection Interface

Typical Specifications

(Customizable based on your model—please confirm specs if needed)

| Parameter | Value |

| Working Width | 450mm |

| Workpiece Thickness | 0.5 – 80mm |

| Minimum Part Size | ~50 × 50mm |

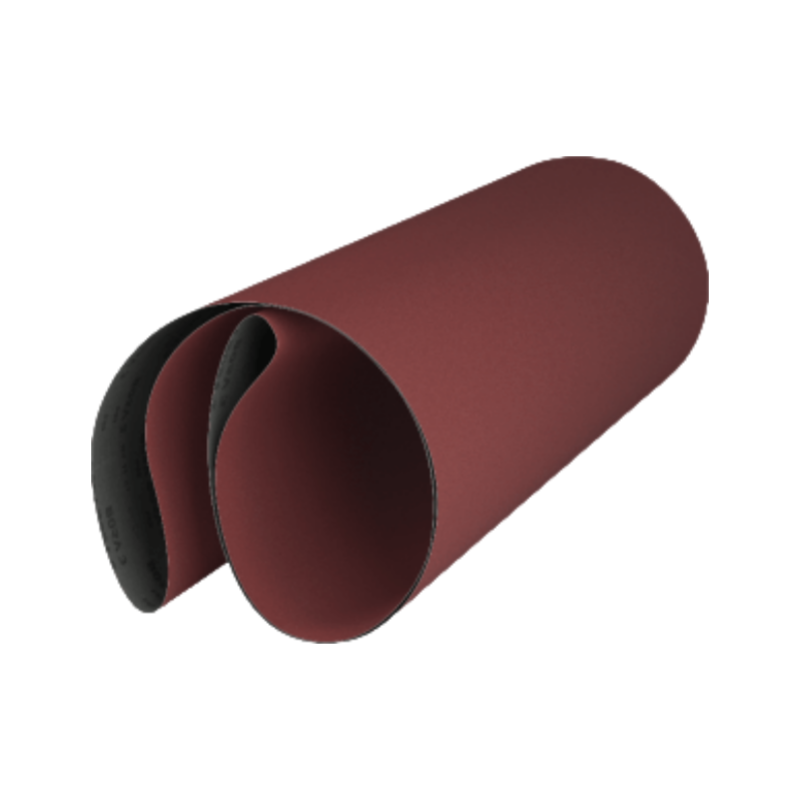

| Abrasive Belt Size | e.g., 1910 × 450mm |

| Brush Diameter | ~300mm |

| Feeding Speed | Adjustable (0.5 – 6 m/min) |

| Main Power | ~18–36.5 kW (depending on configuration) |

| Dust Air Volume | 4000–5000 m³/h |

Applications

Laser cutting, punching, shearing, or plasma-cut parts

Sheet metal deburring and oxide layer removal

Edge rounding up to 2mm radius

Uniform surface brushing or finishing

Pre-treatment before powder coating, welding, or assembly