Introduction to 600KG Metal Sheet Vacuum Lifters

In the industrial sector, handling large and heavy materials like metal sheets and plates requires highly specialized equipment that ensures safety, efficiency, and productivity. Metal sheets, often weighing several hundred kilograms, can be difficult and unsafe to move manually or with basic lifting equipment. To solve this problem, the 600KG Metal Sheet Vacuum Lifters provide an innovative, safe, and highly effective solution for lifting and transporting heavy metal plates with ease.

Our DC12V Metal Plate Vacuum Lifters are designed to handle metal sheets of various sizes, including standard dimensions of 3000*1500 mm and 4000*2000 mm, with a lifting capacity of up to 600 kilograms. These vacuum lifters are perfect for industries where metal sheets are regularly handled, such as construction, manufacturing, steel fabrication, and automotive production.

Key Features and Benefits:

High Lifting Capacity (600KG): Our vacuum lifters are capable of lifting and handling metal sheets weighing up to 600KG, making them suitable for a wide range of industrial applications. Whether you are handling steel, aluminum, or other metal plates, these lifters provide the necessary strength to transport heavy materials without compromising safety.

DC12V Power Supply: The lifters are powered by a DC12V system, making them energy-efficient and easy to operate. The 12V power system ensures smooth, reliable operation without the need for large, complex power sources. This makes the equipment suitable for various environments, including warehouses, factories, and construction sites.

Versatile Lifting Sizes (30001500mm, 40002000mm): These vacuum lifters are designed to accommodate various metal sheet sizes. With standard lifting areas of 3000*1500 mm and 4000*2000 mm, they can handle both small and large sheets, providing flexibility in operations. The adaptable design ensures that the vacuum lifters can be used for different applications, depending on the project requirements.

User-Friendly Operation: The 600KG Metal Sheet Vacuum Lifters feature an easy-to-use interface, ensuring that operators can efficiently control the lifting process. The intuitive design allows for quick adjustments, reducing training time and enhancing workplace productivity. The lifter’s robust yet simple controls ensure that users can focus on their tasks while minimizing downtime.

Safe and Secure Handling: Safety is a priority when handling heavy metal sheets. Our vacuum lifters utilize advanced vacuum suction technology, which ensures a firm grip on the metal plates during lifting and movement. The lifters come with multiple safety features, including automatic suction pressure regulation, vacuum leak detection, and overload protection, ensuring that the lifting process is always secure and risk-free.

Enhanced Productivity: The ability to quickly and safely lift heavy metal sheets reduces manual labor and speeds up the handling process. With faster lifting times and fewer manual interventions, businesses can improve productivity and reduce operational costs. These vacuum lifters are ideal for high-output environments where time is a critical factor.

Durability and Longevity: Built to withstand the harsh conditions of industrial environments, our vacuum lifters are made from high-quality materials, ensuring durability and longevity. The components are designed to resist wear and tear, and the system is built for continuous operation in demanding conditions. Whether in a factory or on a construction site, these lifters offer a reliable solution for years to come.

Applications Across Industries: The 600KG Metal Sheet Vacuum Lifters are highly versatile and can be used across a range of industries. They are particularly useful in:

Metal Fabrication: Moving large sheets of steel, aluminum, or other metals during manufacturing processes.

Automotive Industry: Handling metal components and large panels for vehicle assembly lines.

Construction: Lifting metal sheets and plates for structural work, cladding, and roofing.

Steel Industry: Moving and handling heavy steel plates in steel mills and distribution centers.

Warehouse and Distribution: Efficiently moving metal sheets in storage facilities and warehouses.

Environmentally Friendly Design: In today’s industrial world, energy efficiency and sustainability are important considerations. The DC12V power system is designed to be energy-efficient, reducing overall energy consumption and lowering the environmental footprint of operations. Additionally, the use of durable materials in construction ensures that the vacuum lifters have a long operational life, minimizing waste and the need for frequent replacements.

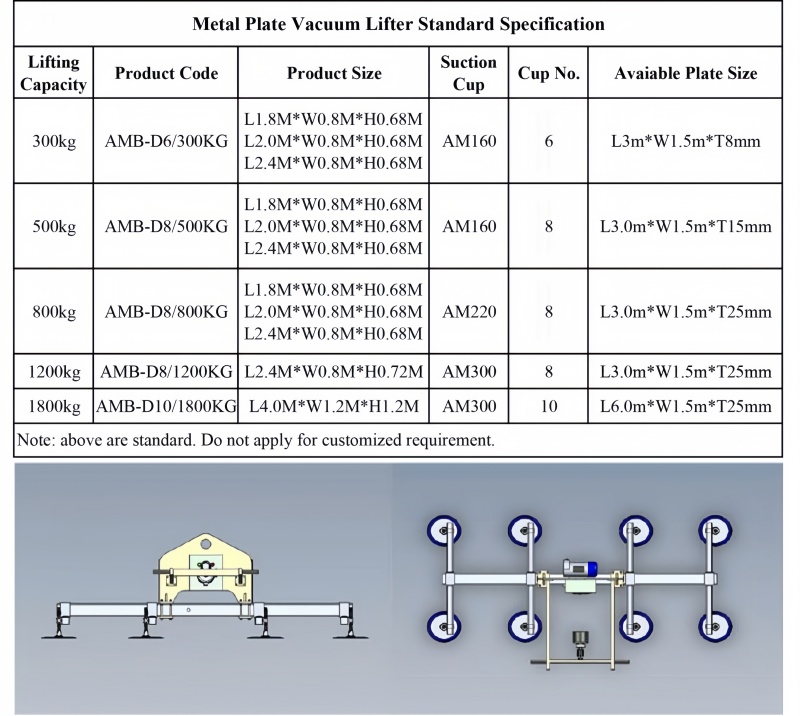

| Product Type | Pneumatic Lifter | Rechargeable Lifter | Plug-in Lifter |

| Model | JS-300-2M/3M | JS-JG300-2M/3M | JS-JG600-2M/3M | JS-JG800-2M/3M | JS-CG300-2M/3M | JS-CG600-2M/3M | JS-CG800-2M/3M |

| Rated Load (kg) | 300 | 300 | 600 | 800 | 300 | 600 | 800 |

| Suction Cup Diameter (mm) | 150 | 150 | 200 | 200 | 150 | 200 | 200 |

| Number of Suction Cups | 8 | 8 | 6 | 8 | 8 | 6 | 8 |

| Dimensions (mm) | 2000*1000 3000*1000 | 2000*1000 3000*1000 | 2000*1000 3000*1000 | 2000*1000 3000*1000 | 2000*1000 3000*1000 | 2000*1000 3000*1000 | 2000*1000 3000*1000 |

| Plate Size (mm) | 3000*1500 4000*2000 | 3000*1500 4000*2000 | 3000*1500 4000*2000 | 3000*1500 4000*2000 | 3000*1500 4000*2000 | 3000*1500 4000*2000 | 3000*1500 4000*2000 |

| Operating Power (V) | 0.8MPa Air Source | DC12V | DC12V | DC12V | AC220V/380V | AC220V/380V | AC220V/380V |

How the 600KG Metal Sheet Vacuum Lifter Works:

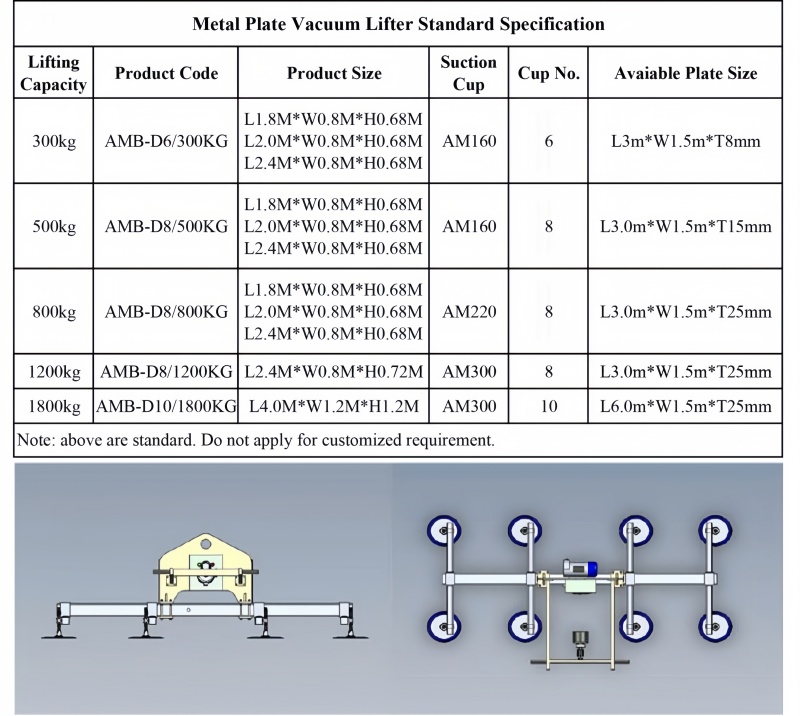

The operation of the DC12V Metal Plate Vacuum Lifter is straightforward yet highly effective. The system uses vacuum suction to create a strong hold on metal plates or sheets. A vacuum pump generates suction power that grips the metal surface firmly, lifting the sheet vertically with ease. The suction strength is adjustable, depending on the size and weight of the plate being handled.

The vacuum lifter comes with rubber pads or suction cups that are designed to protect the surface of the metal sheet while providing a secure grip. The system automatically adjusts the suction power to maintain a stable hold, even as the metal sheet is moved.

Once the sheet is lifted, the operator can move it to the desired location using the lifter’s articulating arm or manipulation system, which can rotate, tilt, or slide the sheet into position. This maneuverability is essential for precise placement of the metal sheets, reducing the need for additional equipment like cranes or hoists.

Maintenance and Support:

Maintaining the 600KG Metal Sheet Vacuum Lifters is simple. Routine inspections and cleaning are recommended to ensure that the vacuum system continues to operate at peak performance. The vacuum pads should be checked for wear, and the suction system should be cleaned regularly to avoid blockages and maintain efficiency.

Our company offers after-sales support and maintenance services to ensure that your vacuum lifter continues to perform optimally throughout its lifespan. Whether you need replacement parts, technical support, or guidance on best practices, we are here to assist you.

Conclusion:

The 600KG Metal Sheet Vacuum Lifters are a highly effective, safe, and efficient solution for lifting heavy metal plates and sheets in a variety of industrial applications. With a lifting capacity of 600KG, versatile lifting sizes, a user-friendly interface, and an energy-efficient DC12V power system, these vacuum lifters offer unparalleled performance. Whether you're in the metal fabrication, automotive, construction, or steel industry, these vacuum lifters will help improve your operational efficiency, reduce manual labor, and ensure safe and precise handling of heavy materials. Choose our 600KG Metal Plate Vacuum Lifters for your business and experience the difference in safety, productivity, and reliability.