1. Main Processing Scope of the Equipment

Processed Products: Stainless steel, carbon steel, aluminum plates, copper plates, and various non-ferrous metals.

Equipment Functions:

This equipment is a combination model featuring a dry sanding belt workstation and four sets of universal sanding disc roller brush workstations. It is mainly used for processing the edges and holes of workpieces to remove burrs, as well as for achieving surface brushing, oxide skin removal, and polishing on metal sheets. It effectively removes burrs generated during processes such as stamping, shearing, laser cutting, plasma cutting, and flame cutting in a single pass, ensuring that all edges and holes of the workpieces achieve a small R-radius effect. The processing is safe and reliable, resulting in perfect quality for the workpieces.

2. Working Principle of the Equipment

The equipment first uses a sanding belt workstation to remove larger burrs, such as slag particles, from the surface of the workpiece. It then employs four sets of universal sanding disc roller brushes, where two adjacent sanding disc brushes rotate in opposite directions, while the brush combination orbits, applying high-speed centrifugal polishing, scraping, cutting, and filing forces to the edges and inner holes of the workpiece. This process removes burrs without leaving dead corners, producing edges and inner holes with a radius of about 0.2-0.5mm (the size of the R-radius can be adjusted by selecting different processes and abrasives). This ensures high processing efficiency.

Additionally, the sanding belt workstation and sanding disc roller brush workstation can operate independently. The sanding belt can independently perform surface brushing, polishing, oxide skin removal, and slag removal on metal sheets. The sanding disc roller brush can operate independently for 360-degree burr removal, especially for laser-cut and CNC-punched metal parts with film coverings. It not only thoroughly removes burrs without damaging the film but also avoids scratching the metal parts. The equipment uses special soft abrasive fibers specifically designed for burr removal, ensuring a burr-free finish on the surface of metal parts, even for irregularly shaped workpieces.

The conveyor system is equipped with strong vacuum suction to securely hold the workpieces. For workpieces larger than 50mm × 50mm (without holes), processing can be done without fixtures, while special workpieces can use supporting fixtures for secure processing. The conveyor system features variable frequency speed adjustment.

The equipment is also equipped with a wet dust collector to reduce safety hazards and effectively handle grinding dust. A top high-pressure, high-flow fan draws the grinding dust into the dust chamber, where it settles in water due to spraying, allowing for environmentally friendly filtration and absorption of the dust, with clean air discharged into the atmosphere. This provides operators with a better working environment and recycles metal powder, promoting environmentally friendly production.

Advantages of Using the Equipment

Improved Production Efficiency: Continuous feeding through-pass processing meets order processing volume demands.

Enhanced Product Quality: High consistency in processed workpieces; surface treatment effects far exceed manual processing results.

Cost Savings: The processing cost per unit area of workpieces is significantly lower than manual processing.

Safety and Environmental Protection: Dust absorption enhances worker safety and improves the working environment.

3. Equipment Structure Diagram and Comparison of Burr Removal Before and After Processing

4. Main Technical Parameters of the Equipment

| Main Technical Parameters of the Equipment | Specifications |

| Processing Width | ≤800mm |

| Processing Thickness | 0.5~80mm |

| Minimum Processing Size | 50mm × 50mm (without holes) |

| Total Power | 30.25KW (excluding dust collection) |

| Sanding Belt Size | Φ1910mm × 800mm |

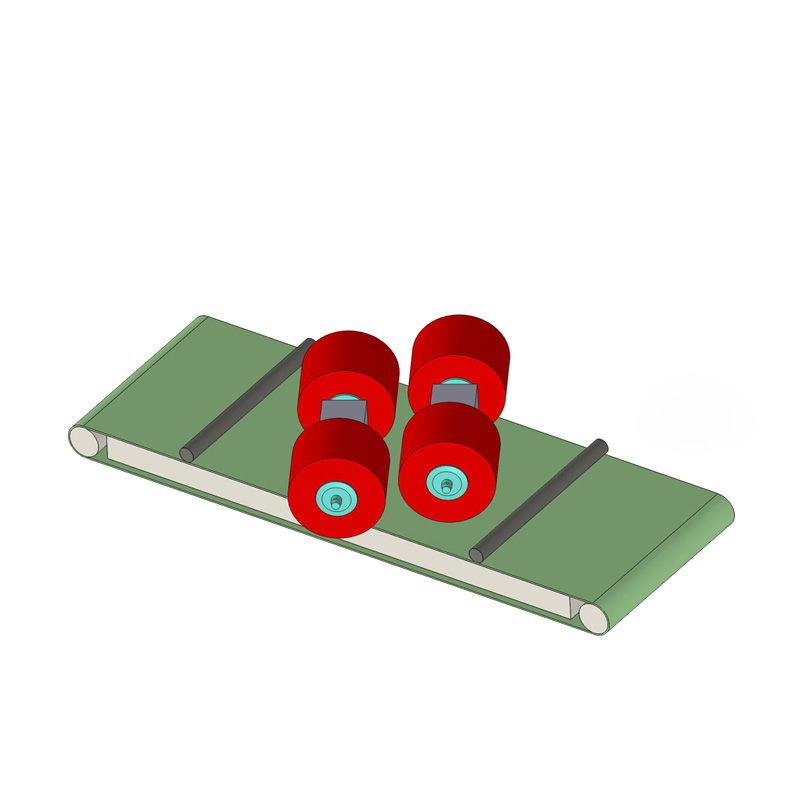

| Sanding Disc Roller Brush Size | Φ300mm × 300mm |

| Conveyor Speed | 0.5~6m/min (variable frequency adjustable) |

| Sanding Belt Linear Speed | Approximately 18m/s |

| Roll Brush Self-Rotation Speed | 8~26m/s (variable frequency adjustable) |

| Roll Brush Orbit Speed | 1~15r/min (variable frequency adjustable) |

| Number of Roll Brush Planetary Rotation Axes | 1 |

| Number of Roll Brush Planetary Self-Rotation Axes | 4 |

| Processing Thickness Servo Adjustment Precision | 0.01mm |

| Roll Brush Compensation Servo Adjustment Precision | 0.01mm |

| Grinding Consumables | Roller brush |

| Dust Collection Air Volume | 4000m³/h |

| Equipment Dimensions | Length 2650mm × Width 1650mm × Height 2150mm |

| Total Weight | Approximately 2.2T |

Benefits

Enhanced Surface Quality: Produces high-quality finishes by removing burrs and achieving smooth edges.

Increased Efficiency: Capable of continuous operation, suitable for high-volume production environments.

Cost Savings: Reduces labor costs associated with manual deburring processes.

Safety Features: Equipped with dust collection systems to maintain a clean and safe working environment.

Applications

Metal Fabrication: Ideal for use in industries such as automotive, aerospace, electronics, and construction.

Sheet Metal Processing: Effective for deburring laser-cut, punched, and sheared metal sheets.

General Manufacturing: Suitable for any application requiring edge finishing and burr removal on metal parts.

Example Models

Compact Roller Brush Deburring Machine: Designed for smaller workshops, offering essential deburring features.

High-Throughput Roller Brush Machine: Suitable for large-scale manufacturing, with multiple brush heads for increased efficiency.