Deburring and Edge Rounding Machine Technical Specifications

| Feature | Specification |

| Material | Steel, Aluminum, Stainless Steel |

| Process | Edge Rounding |

| Material Thickness (mm) | 0.5 - 80 |

| Max. Material Width (mm) | 800 |

| Min. Part Dimensions (mm) | 50 x 50 |

| Max. Material Weight (kg) | 350 |

| Conveyor Speed (m/min) | 0.5 - 6.0 |

| Min. Deduster Need (m³/h) | 3000 |

| Machine Power Consumption (kW) | 22 / 22.8 |

| Machine Weight (kg) | 2100 |

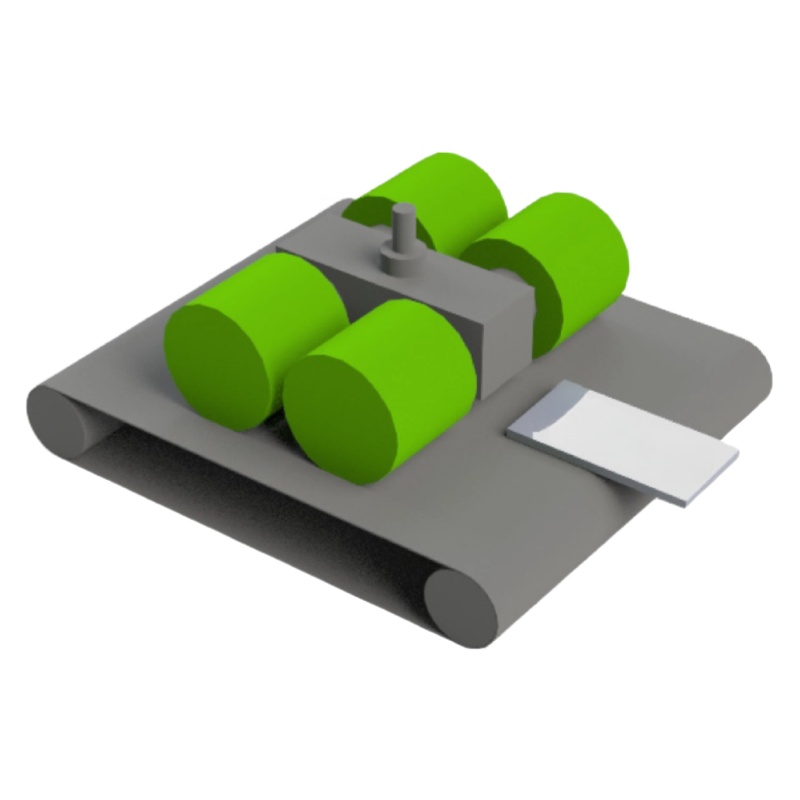

| Holder System | Magnetic (Vacuum Optional) |

| Model | MSP-M800 |

| Conveyor Width | 800mm |

| Working Height | 80mm |

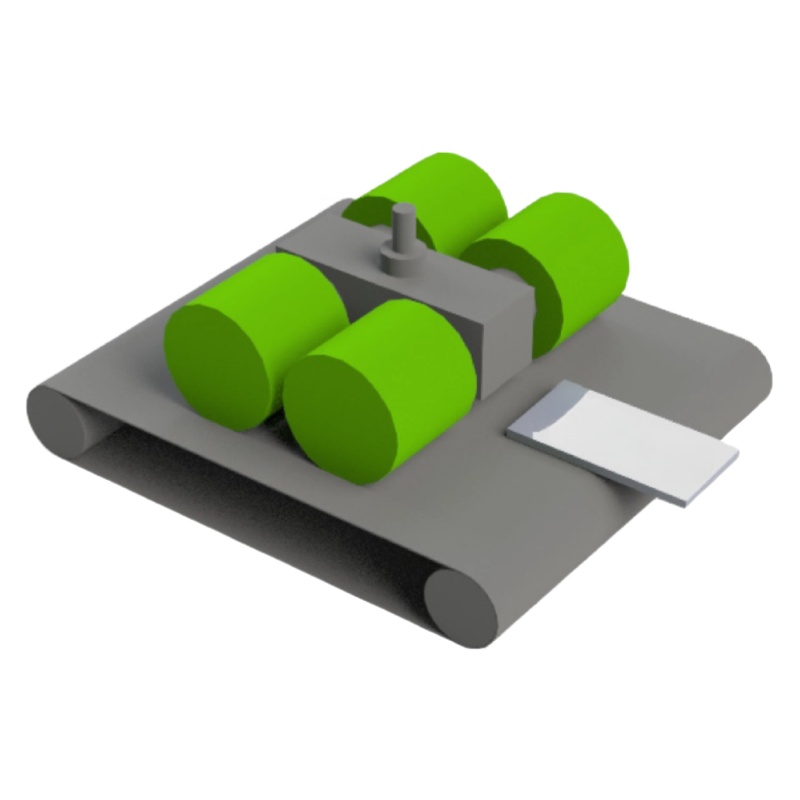

| Flap Wheels Quantity | 4 |

| Flap Wheel Dimensions | Ø300 x 300mm |

| Conveyor Speed | 0.5 - 6.0 m/min |

| Processes | Edge Rounding |

Flap Wheel Specifications

| Flap Wheel Dimension (Diameter) | Flap Wheel Dimension (Length) |

| Ø300mm | 300mm |

Machine Features and Applications

The Deburring and Edge Rounding Machine is designed to effectively clean the burrs formed on metal parts, particularly after flame cutting processes, while rounding off sharp edges and providing a smooth finish. This machine is ideal for treating sheet metal parts, particularly when clean edges and smooth surfaces are required for further processing or for aesthetic purposes.

Key Features:

Edge Rounding: The machine is equipped with a Flap Wheel (Ø300mm) that ensures precise edge rounding, making sharp metal edges smoother and safer for handling.

High Precision: Capable of processing material thicknesses between 0.5mm and 80mm, making it suitable for a wide range of sheet metal parts.

Magnetic Holder System: This system secures the metal parts during the process, providing stability, with the option to use a vacuum system for specific requirements.

Efficient Operation: The machine operates at a variable conveyor speed between 0.5 and 6.0 m/min, allowing for versatile processing depending on part size and complexity.

Durability and Power: With a power consumption of 22 / 22.8 kW, the machine is both powerful and efficient, delivering consistent performance during operation.

Applications:

Deburring: The machine removes burrs formed during cutting processes such as flame cutting, laser cutting, and punching, ensuring clean edges.

Edge Rounding: Provides controlled rounding of sharp edges, making the parts safer for handling and improving their appearance.

Surface Finishing: Achieves a smooth, uniform surface finish on the treated metal parts, which can be critical for both functional and aesthetic purposes.