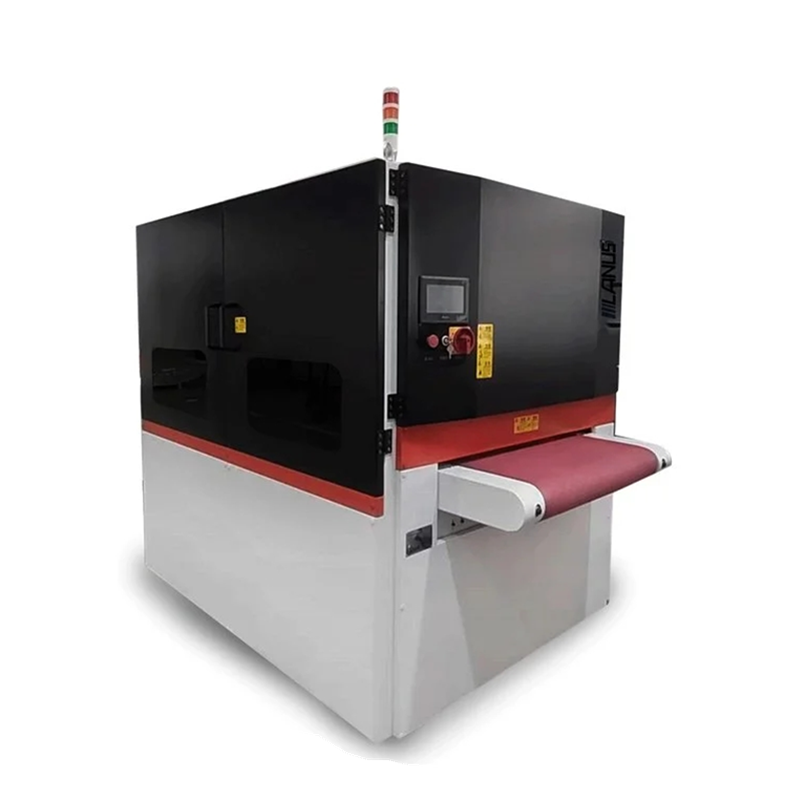

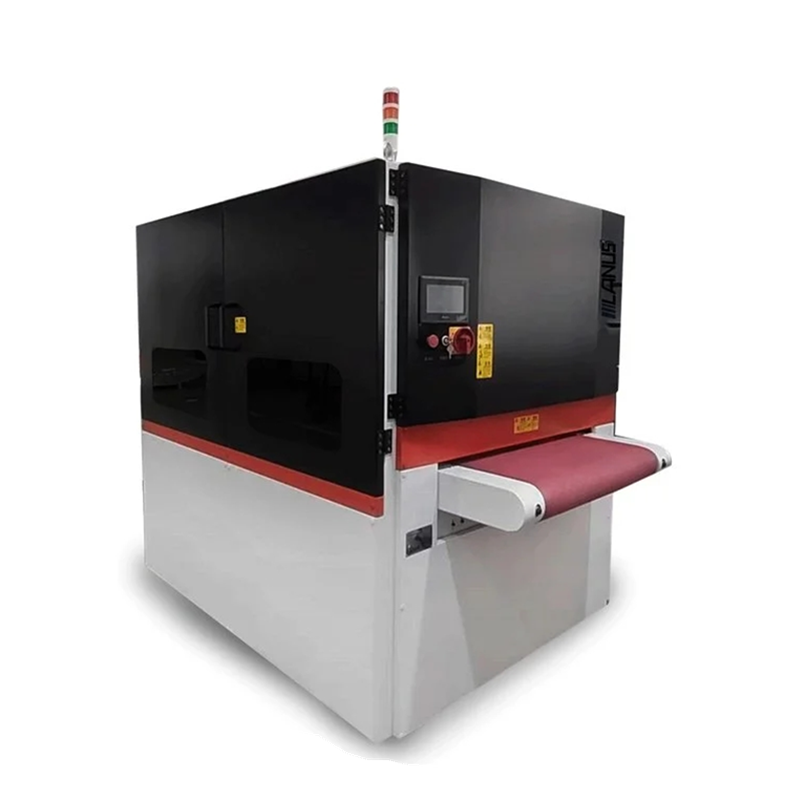

800mm Deburring and Edge Rounding Machine for Removing Burrs from Flame Cutting of Metal Parts

Introduction:The Deburring and Edge Rounding Machine is designed to efficiently remove burrs formed after the flame cutting processes of metal parts, rounding sharp edges to create a smooth surface. This machine is crucial for improving the safety, quality, and appearance of metal parts. By eliminating sharp edges and burrs, it ensures better handling of the parts and improves their suitability for further processing, such as painting or assembly. The machine can process various metals including steel, aluminum, and stainless steel, and is suitable for materials with thicknesses ranging from 0.5mm to 80mm. It is equipped with magnetic holder systems and offers customizable conveyor speeds for optimal processing.

Key Features:

Removes burrs and rounds sharp edges from flame-cut metal parts.

Suitable for processing steel, aluminum, and stainless steel.

Handles material thicknesses from 0.5mm to 80mm.

Maximum material width of 800mm for versatile application.

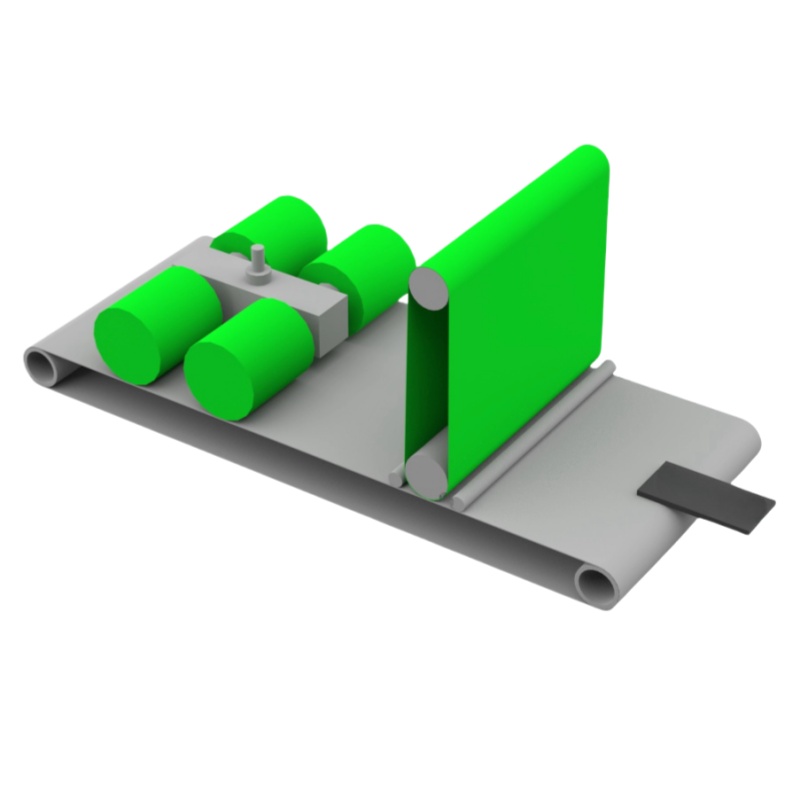

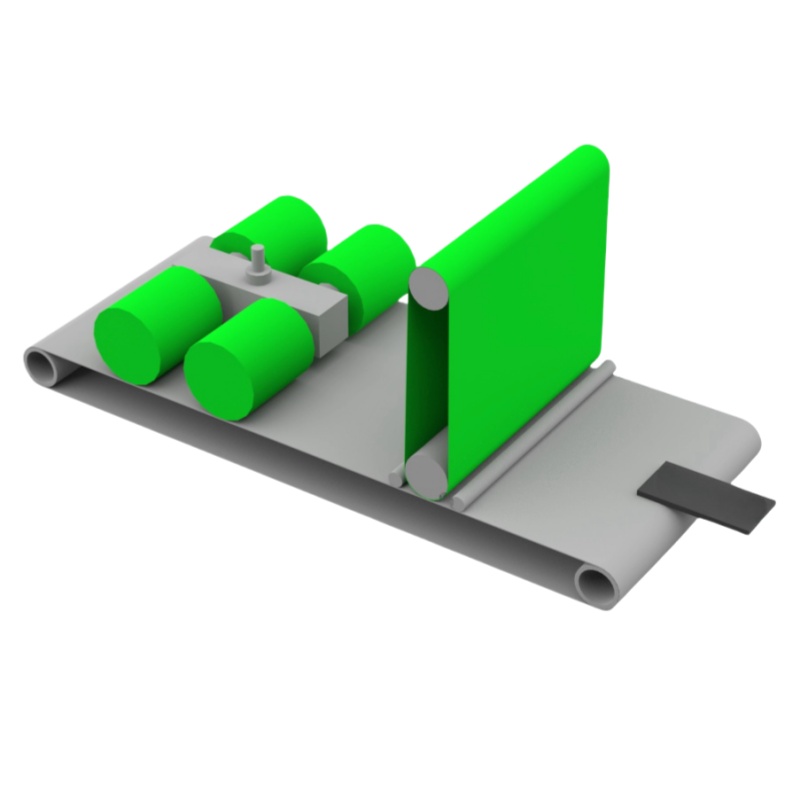

Magnetic holder system, with optional vacuum system for secure material handling.

Adjustable conveyor speed (0.5-6.0 m/min) for varying processing needs.

Efficient dust extraction with a minimum requirement of 3000 m³/h.

Low power consumption for sustainable operation.

Technical Specifications

| Feature | Specification |

| Material | Steel, Aluminum, Stainless |

| Process | Deburring, Edge Rounding |

| Material Thickness (mm) | 0.5 - 80 |

| Max Material Width (mm) | 800 |

| Min Part Dimensions (mm) | 50 x 50 |

| Max Material Weight (kg) | 350 |

| Conveyor Speed (m/min) | 0.5 - 6.0 |

| Min Deduster Need (m³/h) | 3000 |

| Machine Power Consumption (kW) | 33.8 |

| Machine Weight (kg) | 2350 |

| Holder System | Magnetic (Vacuum Optional) |

| Compressed Air Requirement | Minimum 5.0 Bar |

| Flap Wheels Quantity | 4 |

| Flap Wheel Dimensions | Ø300 x 300 mm |

| Conveyor Width | 800 mm |

| Working Height | 80 mm |

| Model | MSP-L800 |

| Processes | Deburring, Edge Rounding |

Flap Wheel Dimensions:

Diameter: Ø300 mm

Length: 300 mm

Available Emery Bands: