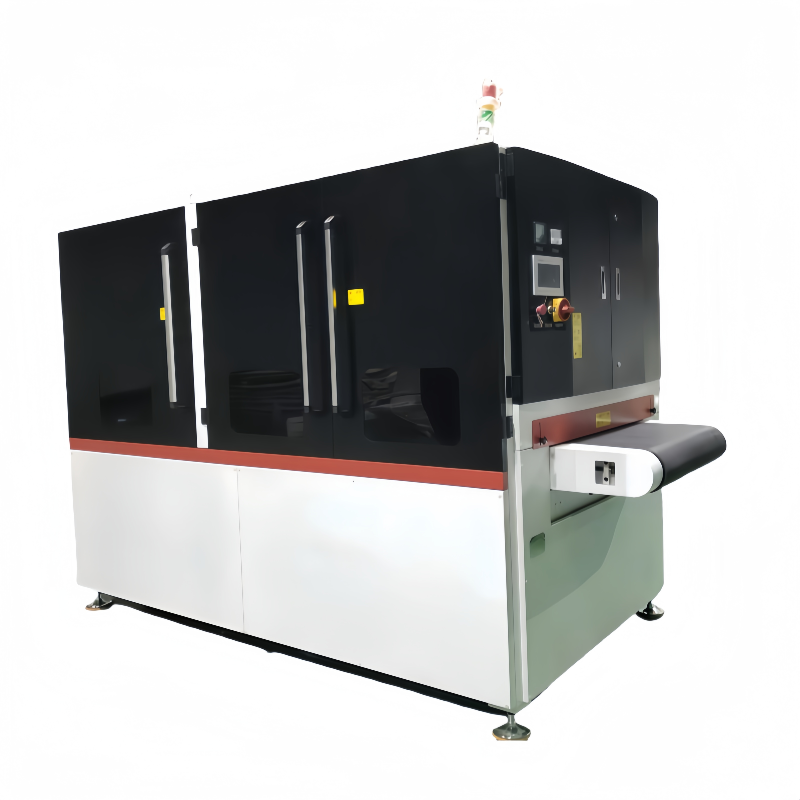

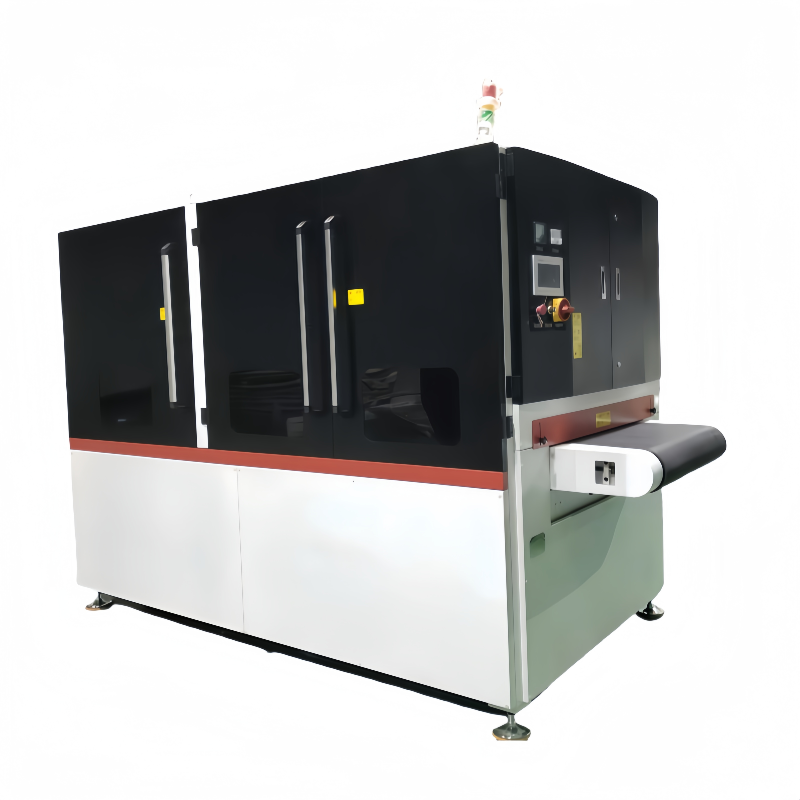

800mm Deburring and Edge Rounding Machine for Heavy Slag Removal

Function & Application

This machine is a dry-type deburring, edge rounding, and heavy slag removal system designed for metal parts processed by flame cutting, plasma cutting, laser cutting, drilling, punching, and shearing. It features a combination of a steel hammer disc brush station, a transverse sanding belt station, and a multi-functional rolling brush unit, ensuring a comprehensive one-pass deburring and finishing.

1. Processing Scope

1.1 Processed Materials:

✔ Carbon Steel Plates

✔ Stainless Steel, Aluminum (Optional)

1.2 Machine Functions:

This dry-type processing machine combines:

Steel Hammer Disc Brush Station

Transverse Sanding Belt Station

Universal Rotary Brush Station

It is designed for deburring, edge rounding, slag removal, polishing, and surface finishing.

✔ Removes burrs and slag from drilling, punching, shearing, laser cutting, plasma cutting, and flame cutting.

✔ Ensures smooth edges and hole contours with a small R arc effect.

✔ Provides safe, reliable processing while maintaining workpiece accuracy.

2. Working Principle

Steel Hammer Disc Brush Station

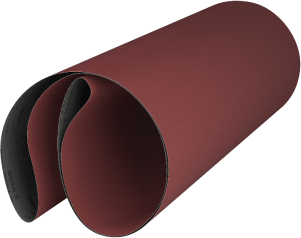

Transverse Sanding Belt Station

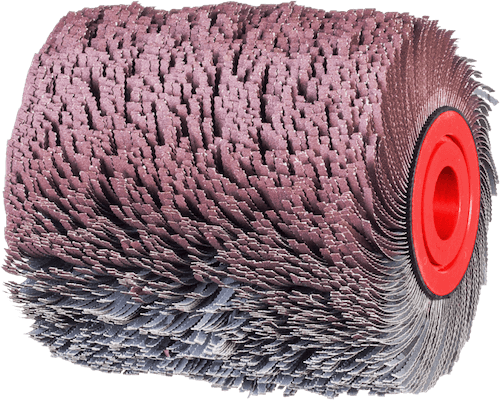

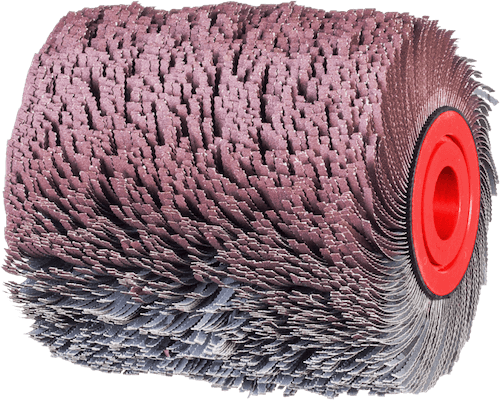

Universal Rotary Brush Station

Equipped with 4 sets of multi-directional abrasive flap brushes.

Adjacent brushes rotate in opposite directions, while the entire brush assembly revolves.

High-speed centrifugal grinding, scraping, shaving, and filing for edge rounding and hole deburring.

Achieves uniform R-chamfering without affecting workpiece accuracy.

Independent Operation Mode:

✔ Steel Hammer Disc Station Alone → Removes slag from workpiece edges.

✔ Sanding Belt Station Alone → Performs surface brushing, polishing, and deburring.

✔ Rotary Brush Station Alone → Achieves 360° burr-free finishing without damaging protective film on sheet metal.

3. Additional Features

✔ Vacuum Worktable:

✔ Variable Frequency Conveyor System:

✔ Wet-Type Dust Collection System:

Integrated high-pressure fan collects metal dust into a wet dust chamber.

Uses water spray filtration to trap metal particles, ensuring clean air discharge.

Provides a safer, cleaner workspace and allows for metal dust recycling.

Key Applications:

✔ Heavy slag removal from flame-cut parts

✔ Deburring and edge rounding for steel, aluminum, and stainless steel

✔ Surface finishing, polishing, and brushing

✔ Oxide removal and uniform edge rounding

✔ Suitable for carbon steel, stainless steel, and aluminum

Technical Specifications

| Feature | Specification |

| Material Compatibility | Steel, Aluminum, Stainless Steel |

| Processes | Heavy Slag Removal, Deburring, Edge Rounding |

| Max. Processing Width | ≤800mm |

| Processing Thickness | 0.5~80mm |

| Min. Processing Size | 50mm × 50mm (Carbon Steel) |

| Total Machine Power | 20.25KW |

| Steel Hammer Disc Brush Size | Φ162mm |

| Abrasive Belt Size | Φ3530mm × 80mm (60# Zirconium Oxide) |

| Roller Brush Size | Φ300mm × 300mm (120# German KSF Brush) |

| Conveyor Speed | 0.5~6 m/min (Adjustable by Frequency) |

| Abrasive Belt Linear Speed | 12 m/s |

| Rolling Brush Rotation Speed | 8~26 m/s (Adjustable by Frequency) |

| Rolling Brush Revolution Speed | 1~15 r/min (Adjustable by Frequency) |

| Planetary Brush Rotation Heads | 4 pcs |

| Planetary Brush Revolution Heads | 1 pc |

| Thickness Servo Adjustment Precision | 0.01mm |

| Brush Compensation Servo Adjustment Precision | 0.01mm |

| Grinding Consumables | Steel Hammer Disc Brush + Abrasive Belt + Rolling Brush |

| Max. Table Load Capacity | ≤400kg |

| Dust Extraction Volume | 5000m³/h |

| Machine Dimensions | 4100mm (L) × 1900mm (W) × 2200mm (H) |

| Machine Weight | ≈3T |

Abrasive Consumables Used

✔ Flap Wheels

✔ Ceramic Emery Band

✔ Zirconium Emery Band

✔ Aluminum Oxide Emery Band

✔ Cubitron Emery Band

✔ Heavy Slag Removal Disc

✔ Scotch Emery Ban