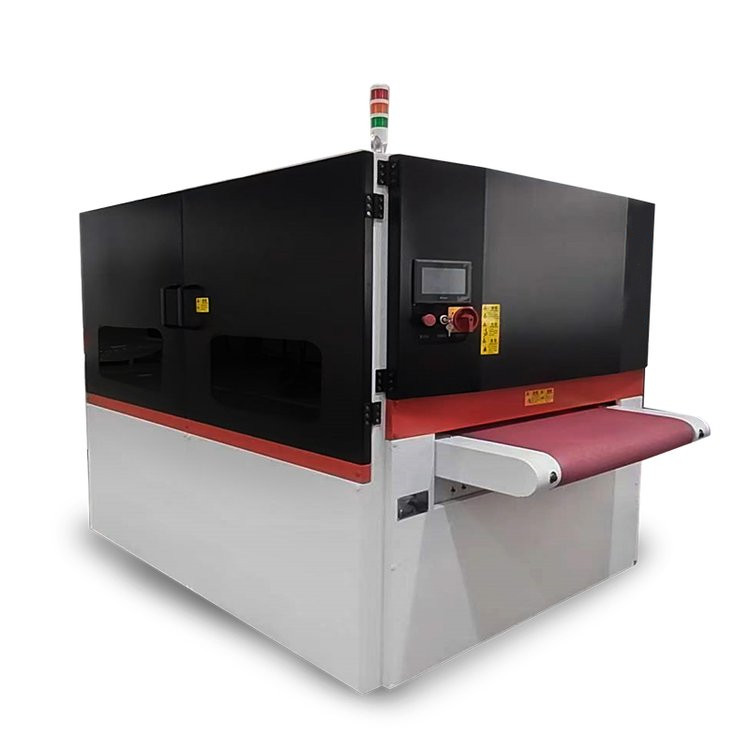

800mm Deburring and Edge Rounding Machine (Three-Station: Sanding Belt + Flap Wheel + Sanding Disc Brush)

The 800mm Deburring and Edge Rounding Machine is a high-performance industrial machine designed for deburring, edge rounding, and finishing metal parts, specifically after processes like flame cutting, plasma cutting, and laser cutting. The machine effectively removes burrs, sharp edges, and oxides, resulting in smooth, rounded edges with a professional finish.

This machine utilizes a combination of sanding belts, flap wheels, and sanding disc brushes to process metal parts with precision. It ensures high efficiency, safety, and consistency in large-scale production environments. The machine is equipped with an advanced servo-driven system for precise thickness adjustments and brush compensation, achieving fine-tuned results for various material types, including steel, aluminum, and stainless steel.

Features and Applications

Material Types: Steel, Aluminum, Stainless Steel

Primary Processes:

Deburring

Edge Rounding

Finishing

Ideal for: Flame cutting, plasma cutting, laser cutting, and shearing applications.

Applications: Suitable for industries such as automotive, aerospace, metal fabrication, and more.

Technical Specifications

| Specification | Details |

| Material | Steel, Aluminum, Stainless Steel |

| Process | Deburring, Edge Rounding, Finishing |

| Processing Width | ≤ 800mm |

| Processing Thickness | 0.5~80mm |

| Minimum Part Size | 50mm x 50mm (for carbon steel) |

| Total Power | 32.25KW |

| Hammer Disc Size | Φ162mm |

| Sanding Belt Size | Φ3530mm × 80mm (60# Zirconia Alumina) |

| Sanding Disc Brush Size | Φ300mm × 300mm (120# Klingspor brand) |

| Conveyor Feed Speed | 0.5~6m/min (adjustable by frequency converter) |

| Sanding Belt Speed | 12m/s |

| Brush Self-Rotation Speed | 8~26m/s (adjustable by frequency converter) |

| Brush Planetary Rotation Speed | 1~15r/min (adjustable by frequency converter) |

| Number of Brush Planetary Rotation Axes | 1 |

| Number of Brush Planetary Self-Rotation Axes | 4 |

| Processing Thickness Servo Adjustment Accuracy | 0.01mm |

| Brush Compensation Servo Adjustment Accuracy | 0.01mm |

| Grinding Consumables | Hammer Disc + Sanding Belt + Sanding Brush |

| Conveyor Table Load Capacity | ≤ 400kg |

| Dust Extraction Airflow | 5000m³/h |

| Machine Dimensions (L x W x H) | 4100mm × 1900mm × 2200mm |

| Total Weight | Approx. 3T |

Machine Benefits:

Versatility: Handles a wide range of materials and thicknesses (from 0.5mm to 80mm).

Precision: Servo-driven systems for high-accuracy thickness adjustments and brush compensation.

Efficiency: Capable of processing parts quickly with adjustable feed speeds, ensuring high throughput.

Dust Control: High-efficiency dust extraction system for a cleaner working environment.

Applications:

Heavy Slag Removal: Ideal for removing slag from plasma and flame cutting.

Deburring: Effectively removes burrs from edges and holes to enhance part quality.

Edge Rounding: Smoothens sharp edges for safety and aesthetic purposes.

Finishing: Provides satin finishing for a clean, polished surface.