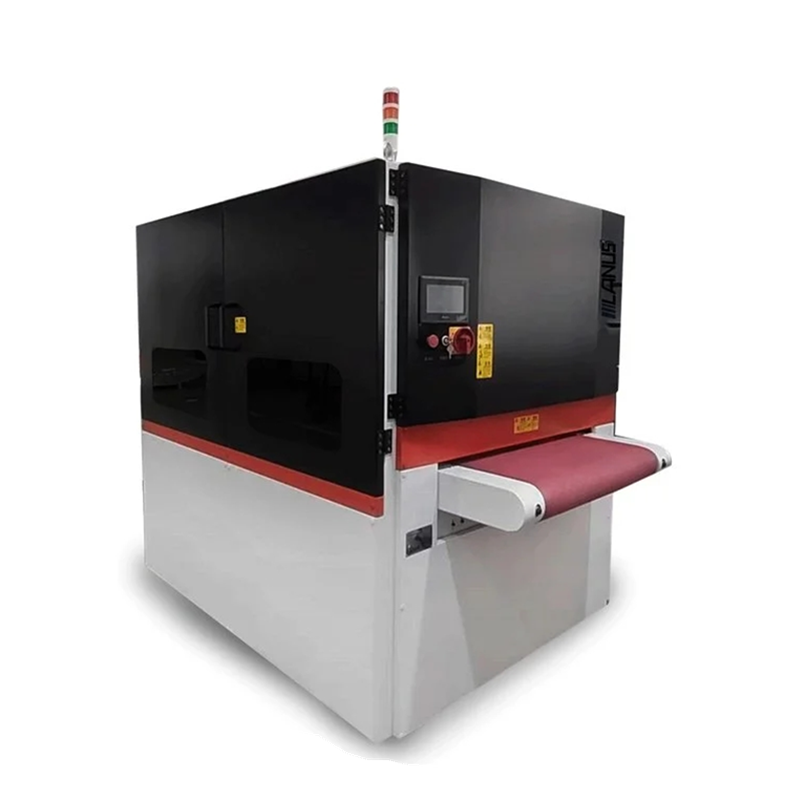

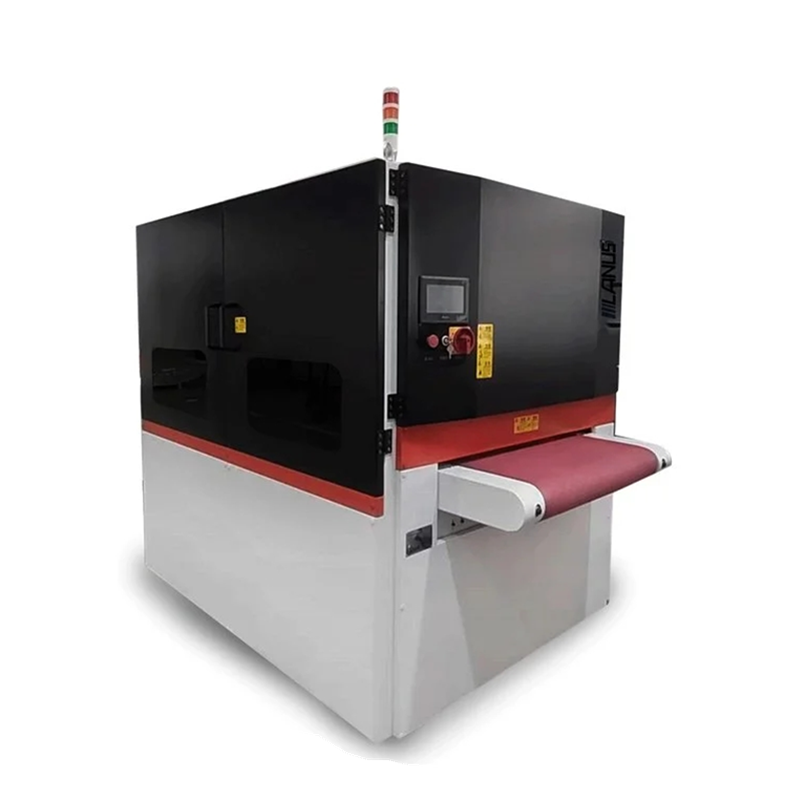

800mm Deburring and Finishing Machine:

The 800mm Deburring and Finishing Machine with 4PCS Flap Wheel + Belt is designed to provide efficient and high-quality deburring, edge rounding, and surface finishing for various materials like steel, aluminum, and stainless steel. Below are its functions and applications:

Functions:

Deburring:

Removes burrs generated from manufacturing processes such as stamping, laser cutting, plasma cutting, and flame cutting.

Provides clean edges by eliminating sharp, uneven surfaces.

Edge Rounding:

Smoothens and rounds the edges of metal parts, providing a consistent and uniform radius, which is crucial for safety, aesthetics, and functionality.

Can achieve radii up to 2mm, depending on the material and process settings.

Surface Finishing:

Improves the surface finish of metal parts by smoothing out rough areas.

Provides a high-quality finish with consistent surface roughness, ensuring the components are ready for further processing or final use.

Multiple Abrasive Options:

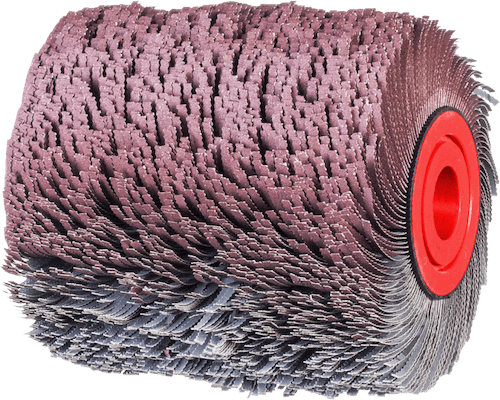

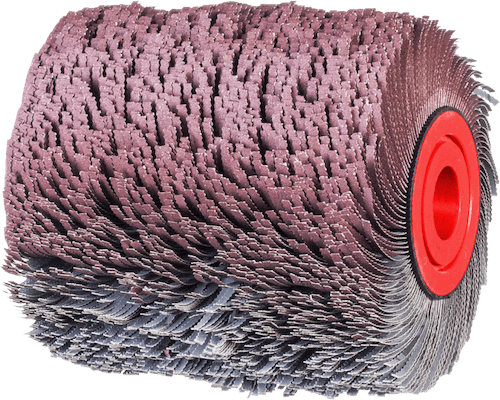

The machine is equipped with 4PCS flap wheels, which are designed to provide superior deburring and finishing performance.

Abrasive options such as ceramic emery, zirconium emery, aluminum oxide emery, and scotch emery bands can be used, allowing for flexibility depending on the material and desired finish.

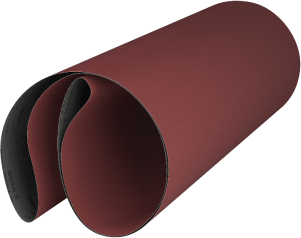

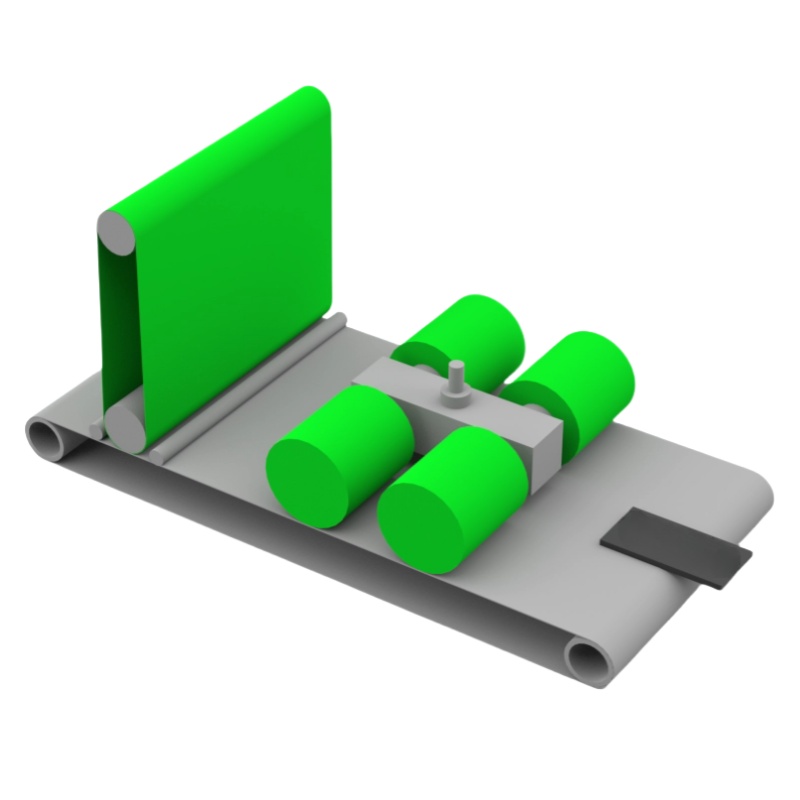

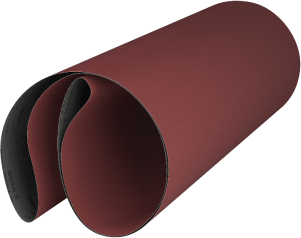

Belt Abrasive Technology:

The combination of flap wheels and sanding belts enables both aggressive deburring and smooth, fine finishing in a single pass.

The belt configuration allows for continuous and even material removal over larger surfaces.

Adjustable Conveyor Speed:

The machine offers adjustable conveyor speeds (0.5 to 6.0 m/min), providing flexibility in controlling the intensity and time for deburring and finishing, suitable for different material types and thicknesses.

Applications:

Metalworking Industry:

Ideal for deburring and edge rounding metal parts used in automotive, aerospace, and machinery manufacturing.

Useful for finishing metal plates, sheets, and parts with complex geometries and edges.

Sheet Metal Processing:

Used in applications such as laser-cut, plasma-cut, or shearing processes, where burrs and sharp edges need to be removed.

Provides a smooth finish for materials of varying thickness (0.5 to 80mm), making it versatile for different types of sheet metal.

Automotive and Aerospace:

Commonly used for finishing parts like body panels, frames, and brackets, ensuring that edges are smooth and free from sharp burrs for safety and aesthetic purposes.

Ensures high-precision edge radii for parts in critical applications.

Construction and Structural Applications:

Suitable for deburring metal parts used in the construction of buildings, bridges, and other structures, ensuring all edges are free from burrs and are properly rounded.

Improves part quality and reduces the risk of injuries during handling and installation.

Precision Parts and Components:

General Manufacturing:

For general-purpose metal processing where deburring and edge rounding are needed, such as parts used in machinery, equipment, and consumer goods.

| Feature | Specification |

| Material | Steel, Aluminum, Stainless Steel |

| Process | Deburring, Edge Rounding |

| Material Thickness (mm) | 0.5 - 80 mm |

| Max. Material Width (mm) | 780 mm |

| Min. Part Dimensions (mm) | 50 x 50 mm |

| Max. Material Weight (kg) | 350 kg |

| Conveyor Speed (m/min) | 0.5 - 6.0 m/min |

| Min. Deduster Need (m³/h) | 3000 m³/h |

| Machine Power (kW) | 20.8 kW |

| Machine Weight (kg) | 2350 kg |

| Holder System | Magnetic (Vacuum Optional) |

| Compressed Air Requirement | Minimum 5.0 Bar |

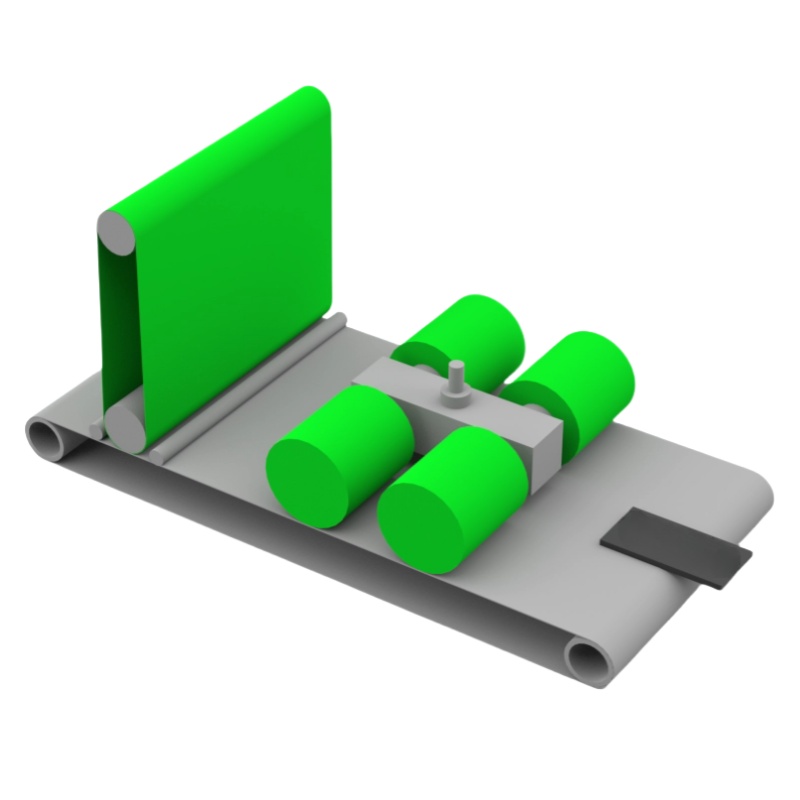

Model-Specific Details (MSP-L800S)

| Specification | Value |

| Flap Wheels Quantity | 4 |

| Flap Wheels Dimensions | Ø300 x 300 mm |

| Conveyor Width | 780 mm |

| Working Height | 80 mm |

| Conveyor Speed | 0.5 - 6.0 m/min |

| Power Consumption | 20.8 kW |

| Processes | Deburring, Edge Rounding |

Flap Wheel

| Material Type | Usage |

| Ceramic Emery Band | High-performance deburring and finishing |

| Zirconium Emery Band | Heavy-duty deburring for tough materials |

| Aluminum Oxide Emery Band | General-purpose deburring |

| Cubitron Emery Band | Fast material removal, long-lasting |

| Scotch Emery Band | Polishing and finishing |