1. Main Processing Range of the Equipment

Processed Products: Carbon steel, stainless steel, aluminum sheets, copper plates, and various non-ferrous metals, etc.

Equipment Function: This equipment is a combination machine featuring a dry steel hammer disc brush station, a sanding belt station, and eight sets of universal sanding disc roller brush stations. It is primarily used for processing workpiece edges, hole burr removal, and achieving surface treatments such as slag removal, deburring, and polishing of metal plates. It effectively removes burrs generated during processes like stamping, shearing, laser cutting, plasma cutting, and flame cutting. The equipment removes burrs from all edges and holes in one pass, ensuring that the edges and holes of the workpiece achieve a small R radius. The processing is safe, reliable, and ensures the workpiece attains perfect quality.

2. Working Principle of the Equipment

The equipment first uses a set of horizontally swinging steel hammer brush discs to strike and remove slag particles and burrs from the workpiece surface. Then, a sanding belt station removes residual burrs by sanding the surface. Finally, eight sets of universal sanding disc roller brushes rotate in reverse directions, with the disc brushes orbiting around, performing high-speed centrifugal polishing, scraping, shaving, and filing on the workpiece's edges and inner holes. This multi-action ensures burrs are removed from all angles, resulting in uniform R corners (the size of which can be adjusted by selecting different processing methods and abrasives). The equipment achieves high processing efficiency.

At the same time, the steel hammer station, sanding belt station, and sanding disc roller brush stations can also operate independently:

The steel hammer station can independently remove slag from the edges of the workpiece.

The sanding belt station can independently perform surface brushing, polishing, oxide skin removal, and slag removal.

The sanding disc roller brush station can independently perform 360-degree burr removal, especially for workpieces with protective films after laser cutting or CNC punching, ensuring that burrs are removed cleanly without damaging the film or scratching the sheet metal. This equipment uses special soft abrasive filaments designed specifically to address the characteristics of burrs, making it a burr-removal device that does not damage the surface of sheet metal, even when the film is applied, and also has superior processing efficiency for irregular workpieces.

The conveyor system uses powerful permanent magnetic adsorption to securely hold the workpiece in place, enabling through-feed processing for workpieces larger than 50mm x 50mm (non-holed workpieces) without the need for fixtures. Special workpieces can be processed with custom fixtures. The conveyor system features variable frequency and stepless speed adjustment.

The equipment is also equipped with a wet-type dust collector to reduce safety hazards. It efficiently handles grinding dust by using a high-pressure, high-flow fan at the top to draw the dust into the dust collection chamber. Through water spraying, the dust settles in the water and is filtered for environmental absorption, with clean air being released into the atmosphere. This provides workers with a better working environment and recycles grinding metal powder, achieving an environmentally friendly production process.

3. Advantages of Using the Equipment

Increased Production Efficiency: Continuous feeding through-feed processing meets the demands of order volume.

Improved Product Quality: The processed workpieces exhibit consistent quality, and the surface treatment effect far exceeds manual processing.

Cost Savings: The cost per unit area of the workpiece is much lower than manual processing.

Safety and Environmental Protection: Dust absorption ensures worker safety and improves the working environment.

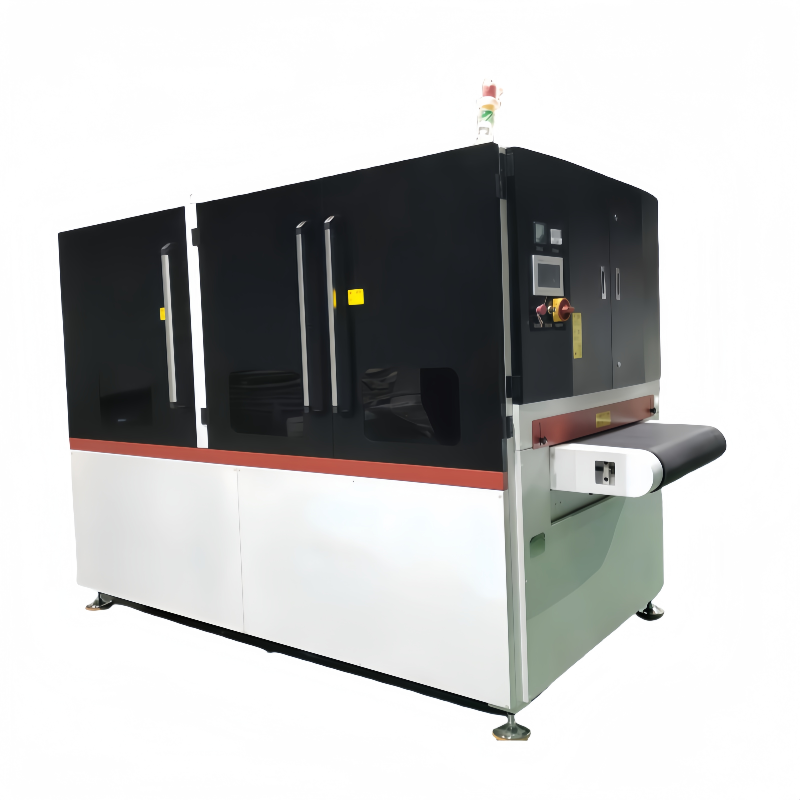

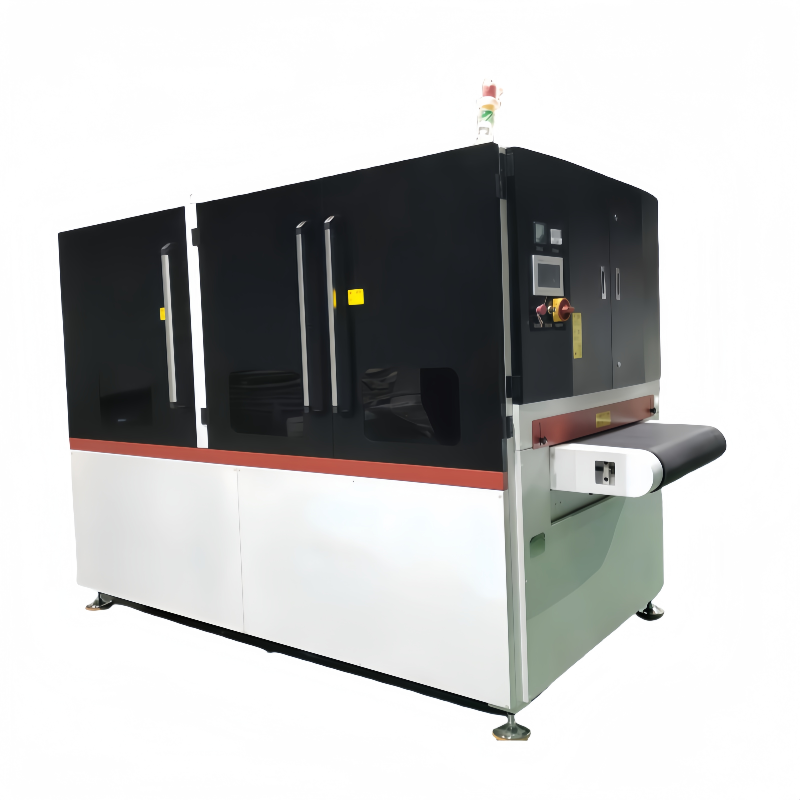

4. Equipment Structure Diagram

5. Main Technical Parameters of the Equipment

| Processing Width | ≤800mm |

| Processing Thickness | 0.5~80mm |

| Minimum Processing Size | 50mm × 50mm (for solid workpieces) |

| Total Machine Power | 30.25KW |

| Hammerhead Disc | Φ162mm |

| Sand Belt Size | Φ1910mm × 800mm |

| Disc Brush Size | Φ300mm × 300mm |

| Conveyor Speed | 0.5~6 m/min, adjustable by frequency (Suggest 0.8-1m/min) |

| Sand Belt Linear Speed | 18 m/s |

| Disc Brush Rotation Speed | 8~26 m/s, adjustable by frequency |

| Disc Brush Revolution Speed | 1~15 r/min, adjustable by frequency |

| Number of Planetary Revolution Brush Heads | 1 pcs |

| Number of Planetary Rotation Brush Heads | 4 pcs |

| Processing Thickness Servo Adjustment Precision | 0.01mm |

| Brush Compensation Servo Adjustment Precision | 0.01mm |

| Grinding Consumables | Hammerhead Disc Unit + Abrasive Belt Unit + Rotary Brush Head |

| Dust Extraction Volume | 4 (units) |

| Approximate Equipment Dimensions | Length 4100mm × Width 1900mm × Height 2200mm |

| Approximate Machine Weight | 3.5T |

6. Main Equipment Configuration List

| Item Name | Specification/Model | Quantity | Function | Brand |

| Hammerhead Disc | Φ162mm | 6 pcs | For slag | / |

| Hammerhead Main Motor | 5.5KW | 1 pcs | For Hammerhead disc rotation | SHIYANG |

| Hammerhead Oscillation Motor | 750W | 1 pcs | For Hammerhead disc oscillation | SHENGBANG |

| Sand Belt Main Grinding Wheel | Φ280mm × 80mm | 1 pcs | For sand belt grinding | / |

| Sand Belt Main Motor | 5.5KW | 1 pcs | For sand belt power | SHIYANG |

| Brush Rotation Motor | 4KW | 4 pcs | For brush spindle rotation power | SHIYANG |

| Brush Revolution Reduction Motor | 750KW | 1 pcs | For brush revolution power | SHENGBANG |

| Brush Lifting Servo Motor | 750W | 1 pcs | For brush wear compensation | VEICHI |

| Rubber Conveyor Belt | Width 800mm | 1 pcs | For feeding and conveying | / |

| Conveyor Drive Motor | 3KW | 1 pcs | For conveyor power | RAPOO |

| Conveyor Reducer | BKA87 | 1 pcs | For conveyor transmission | RAPOO |

| Workbench Lifting Servo Motor | 750W | 1 pcs | For processing thickness adjustment | VEICHI |

| Sand Belt Tracking Sensor | / | 1 pcs | For sand belt tracking signal | SHANGHAI HUGONG |

| Tension Cylinder | ACQ80×30 | 1 pcs | For sand belt tensioning | AIRTAC |

| Tracking Cylinder | SDA63×5 | 1 pcs | For sand belt tracking | AIRTAC |

| Hammerhead Rotation Inverter | 5.5KW | 1 pcs | For adjusting speed of four Hammerhead | VEICHI |

| Brush Rotation Inverter | 5.5KW | 1 pcs | For adjusting speed of four brush sets | VEICHI |

| Brush Revolution Inverter | 750W | 1 pcs | For brush revolution speed control | VEICHI |

| Conveyor Motor Inverter | 3KW | 1 pcs | For conveyor speed control | VEICHI |

| High-Speed Bearings | / | 1 set |

| NSK |

| Low Voltage Electrical Components | / | 1 set | For electrical control | CHNT |

| Control System | PLC | 1 set | For overall machine control | VEICHI |

| Touch Screen | 7-inch | 1 set | For overall machine control | VEICHI |

7. Installation Requirements:

7.1 Sufficient level installation space (4m × 5m).

7.2 380V, 50HZ power supply (±10%).

7.3 Clean compressed air source.

8. Accompanying Documentation:

(Two copies of the user manual, including the following content, and a set of random tools) 8.1 Mechanical schematic diagram

8.2 Electrical schematic diagram

8.3 Specifications and models of consumable parts

8.4 Product certificate of conformity

8.5 One detailed instruction manual