Surface Deburring Machine Technical Specifications

| Feature | Specification |

| Material | Steel, Aluminum, Stainless Steel |

| Process | Deburring |

| Material Thickness (mm) | 0.5 - 80 |

| Max. Material Width (mm) | 800 |

| Min. Part Dimensions (mm) | 50 x 50 |

| Max. Material Weight (kg) | 350 |

| Conveyor Speed (m/min) | 0.5 - 6.0 |

| Min. Deduster Need (m³/h) | 3000 |

| Machine Power Consumption (kW) | 14.5 / 22 |

| Machine Weight (kg) | 2250 |

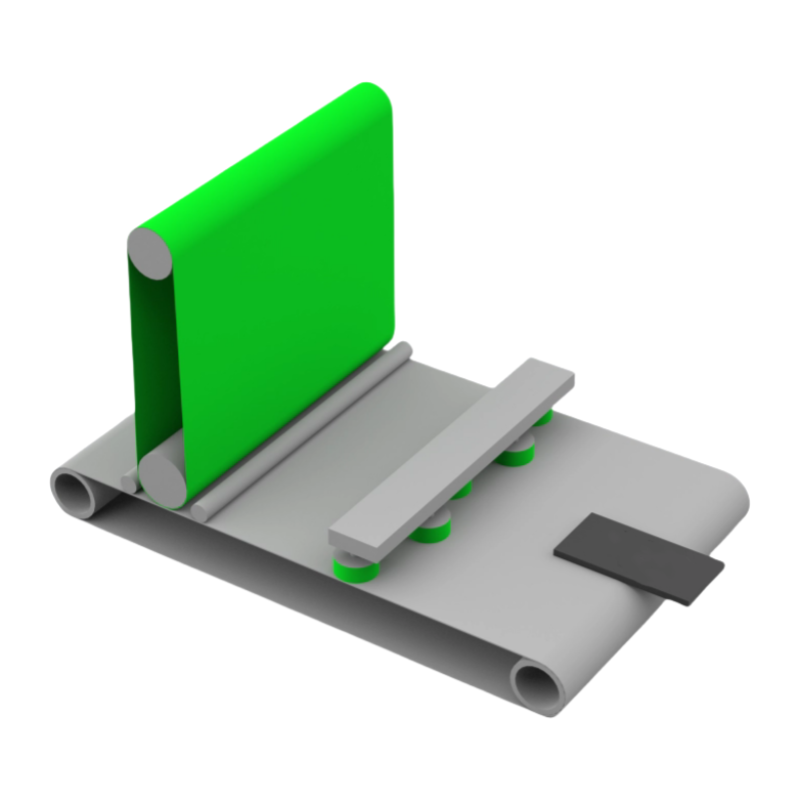

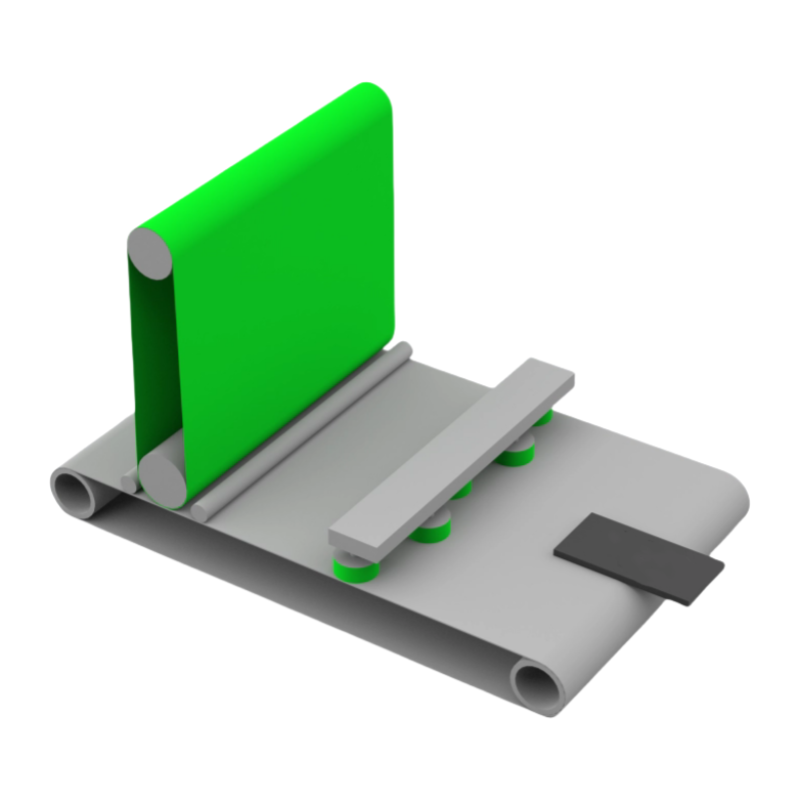

| Holder System | Magnetic (Vacuum Optional) |

| Model | MSP-800 |

| Conveyor Width | 800mm |

| Working Height | 80mm |

| Flap Wheels Quantity | Not Specified |

| Conveyor Speed | 0.5 - 6.0 m/min |

| Power Consumption | 14.5 kW |

| Processes | Deburring |

Machine Features and Applications

This Surface Deburring Machine is designed for cleaning burrs and achieving a smooth surface on metal parts, particularly after flame cutting processes. It can process materials like steel, aluminum, and stainless steel, and is well-suited for deburring and edge treatments on parts ranging from small to medium sizes.

Key Features:

Heavy Slag Removal and Deburring: Equipped with Heavy Slag Removal Disc + Belt workstations, it removes slag, burrs, and provides a chamfering or edge rounding effect on sheet metal.

High Efficiency: The machine operates at a conveyor speed of 0.5 to 6.0 m/min, providing quick and efficient deburring while maintaining consistent results.

Multiple Abrasive Options: Compatible with various abrasive materials including Ceramic Emery Bands, Zirconium Emery Bands, Aluminum Oxide Emery Bands, Cubitron Emery Bands, and Scotch Emery Bands, allowing for a range of surface treatments based on material type and required finish.

Versatile Workholding: The magnetic holder system ensures secure part placement during processing, with the option for a vacuum system for specific parts.

Wide Range of Thickness: Capable of handling material thicknesses from 0.5mm to 80mm, making it suitable for a variety of parts, from small precision components to larger sheets.

Applications:

Deburring: Efficiently removes burrs and slag formed during flame cutting or other processes.

Surface Finishing: Achieves smooth, clean edges, improving both the visual and functional quality of the parts.

Edge Rounding & Chamfering: Provides a controlled radius or chamfer on part edges, which is crucial for certain applications that require smooth and rounded edges for safety or aesthetic purposes.