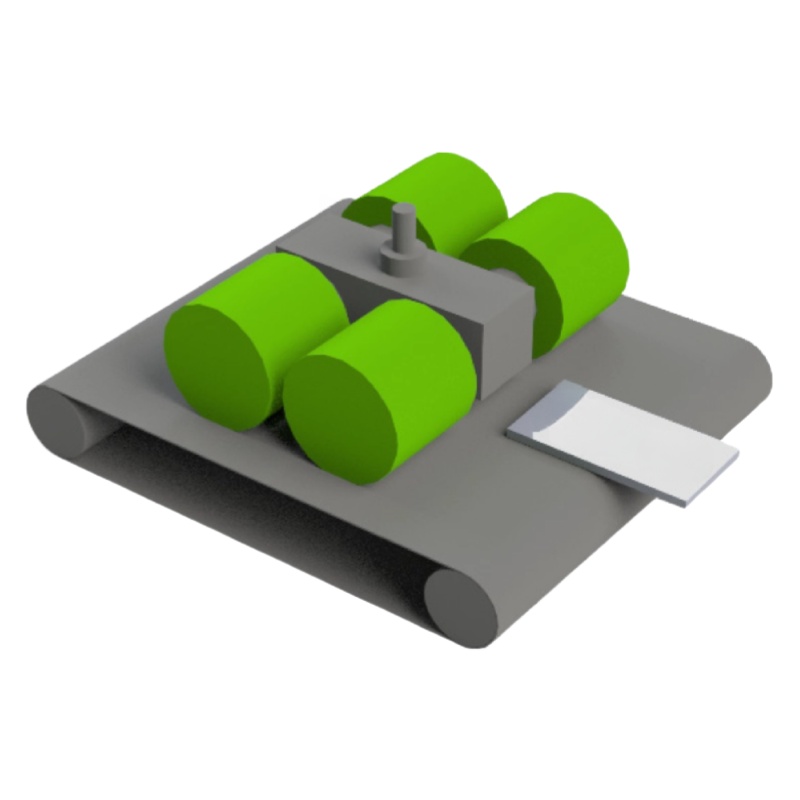

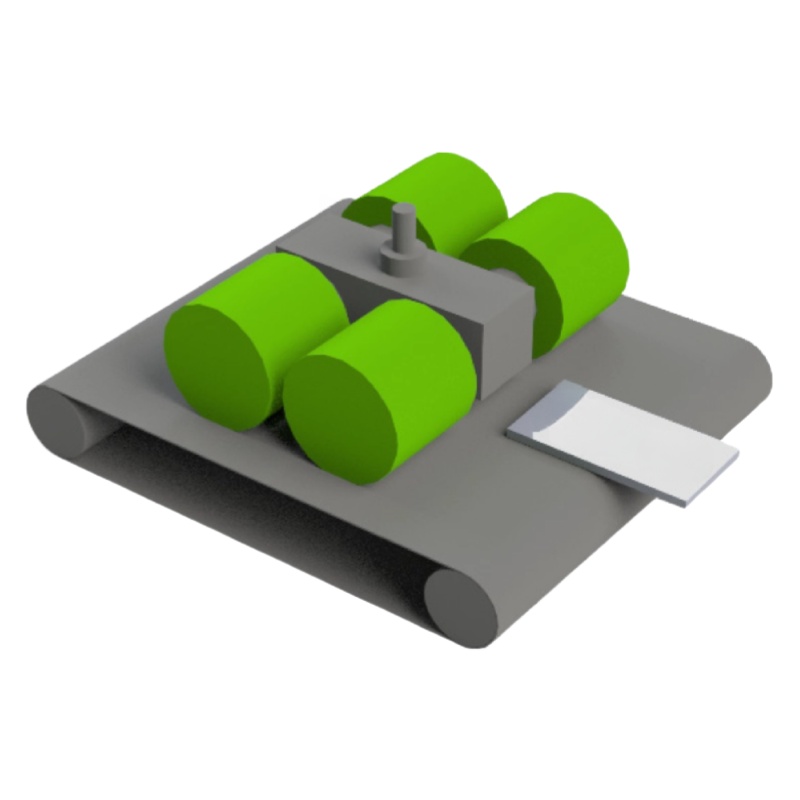

800mm Metal Deburring and Edge Rounding Machine with 4pcs Flap Wheels

The 800mm Metal Deburring and Edge Rounding Machine equipped with 4pcs flap wheels is a versatile and efficient solution for deburring, edge rounding, and surface finishing of metal parts. It is specifically designed to improve the quality of laser-cut, punched, or sheared metal parts by providing smooth, polished edges and surfaces.

Key Features and Benefits

Efficient Deburring: The machine is designed to remove burrs from metal edges, which are common after cutting processes such as laser cutting, plasma cutting, or shearing. This ensures smoother, safer edges for further processing or assembly.

Edge Rounding: It can round sharp edges, providing a more professional and safer finish. This feature is particularly important for parts that will be handled frequently or require smooth edges to meet industry standards.

4 Flap Wheels: The machine is equipped with 4 flap wheels that offer high efficiency and flexibility in deburring and edge rounding operations. These wheels deliver consistent abrasive action, ensuring an even finish across all edges of the parts.

Wide Working Capacity: With a working width of 800mm, the machine can accommodate a wide range of metal parts, including small to medium-sized sheets or components, enhancing its versatility.

Improved Productivity: The design and operation of the machine significantly reduce the time and manual effort required to deburr and round edges, increasing overall productivity in industrial applications.

High-Quality Finish: The machine provides a uniform finish with minimal variation, ensuring consistency in part quality. The flap wheels effectively remove imperfections while leaving a smooth surface.

Applications: This machine is ideal for deburring and edge rounding of parts in industries such as automotive, aerospace, metal fabrication, and electronics. It is particularly suited for laser-cut, punched, or sheared metal sheets and components.

Applications

Laser-Cut Parts: Deburring and rounding the edges of metal parts cut with lasers, ensuring a cleaner and safer finish.

Punched and Sheared Parts: Removing burrs from edges created during punching or shearing operations, improving the quality and safety of the final product.

General Metal Fabrication: Ideal for a variety of metal types, including carbon steel, stainless steel, aluminum, and more.

Technical Specifications

| Feature | Specification |

| Working Width | 800mm |

| Number of Flap Wheels | 4 pcs |

| Flap Wheel Size | 300mm (diameter) x 300mm (thickness) |

| Machine Dimensions | 2500mm (L) x 1500mm (W) x 1800mm (H) |

| Weight | 2200 kg |

| Voltage | 380V / 50Hz |

| Noise Level | ≤ 75 dB |

| Working Efficiency | High, continuous operation |

| Application | Laser-cut, punched, and sheared metal parts |

How It Works

The 800mm Metal Deburring and Edge Rounding Machine is designed to handle a variety of metal types, including steel, aluminum, stainless steel, and copper. The machine features 4 flap wheels, which are designed to offer smooth and effective abrasiveness for deburring and edge rounding. The abrasive belt efficiently removes burrs, while the flap wheels are able to round edges with precision.

The machine uses a belt and flap wheel system to ensure both deburring and rounding in one operation. The flap wheels are mounted in a configuration that allows for optimal flexibility and can be adjusted to work on different thicknesses of metal parts, from thin sheets to thicker components. The feed speed is adjustable, allowing users to control the processing speed based on the material and required finish.

The dust extraction port ensures that the environment remains clean during operation by collecting the debris produced during the deburring and edge rounding processes.