800mm Rotary Brush Deburring Machine for Deburring, Edge Rounding, Oxide Removal & Surface Finishing

✅ Product Overview:

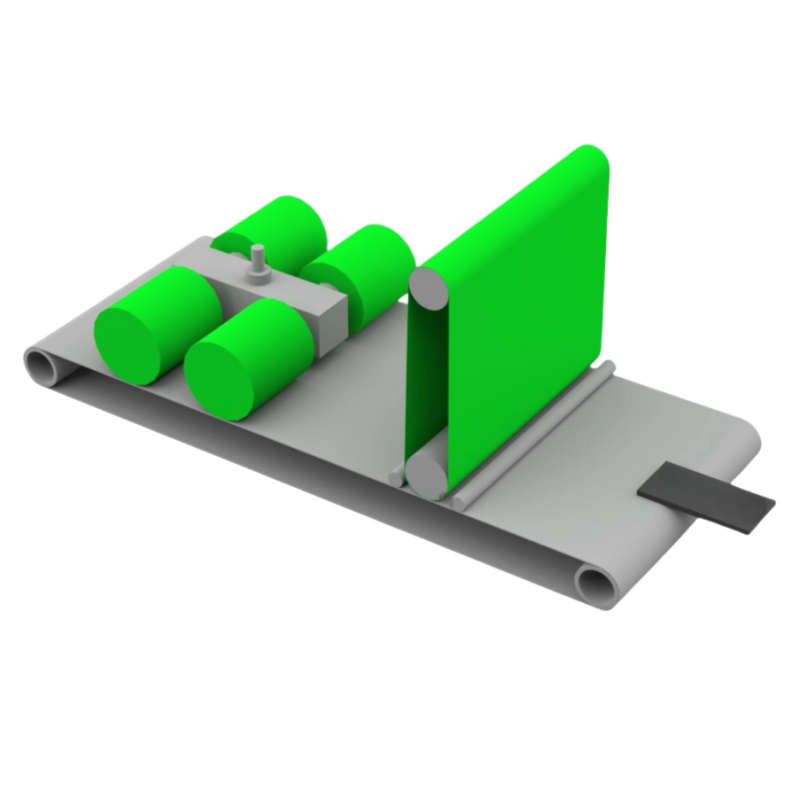

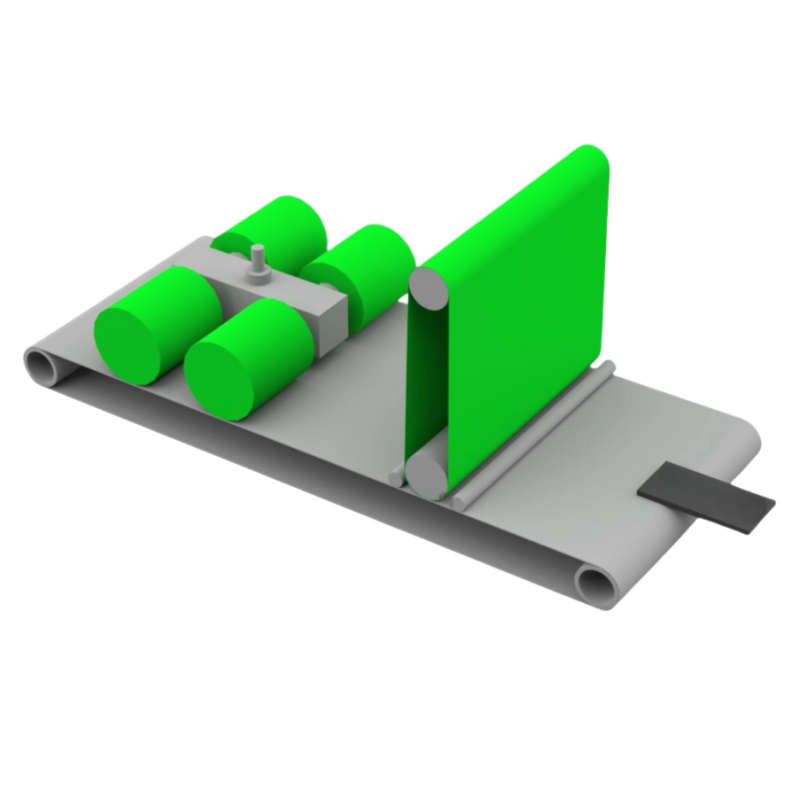

The 800mm Rotary Brush Deburring Machine is a powerful, multi-functional finishing system designed for deburring, edge rounding, oxide removal, and surface finishing of sheet metal parts.

Equipped with both an abrasive belt unit and an advanced rotary brush head, it provides all-in-one post-processing for laser-cut, plasma-cut, waterjet-cut, and punched parts.

Its combination of rotary brush technology and abrasive belt with contact drum ensures outstanding results, whether you're deburring, achieving decorative surface finishes, or preparing parts for welding, coating, or painting.

Key Features & Functionalities:

Rotary Brush Head (Advanced Version):

Equipped with 4 counter-rotating brushes oscillating around a vertical axis for 360° edge processing

Achieves uniform edge rounding up to R0.5 mm

Allows simultaneous use of two brush types (e.g., lamella + wire)

Individually adjustable outer and inner brush RPM and height

Multi-Mode Processing:

Abrasive Belt Unit with Contact Drum:

⚙️ Quick-Change System:

Permanent Magnetic Track:

Rotating Conveyor Cleaning Brush:

️ Dust Extraction Compatibility:

Technical Specifications:

| Parameter | Value |

| Working Width | 800 mm |

| Workpiece Thickness | 0.8 – 80 mm |

| Minimum Part Size | 50 × 50 mm |

| Edge Rounding Radius | Up to 0.5 mm |

| Brush Quantity | 4 counter-rotating rotary brushes |

| Supported Materials | Stainless steel, mild steel, aluminum, copper, etc. |

| Dust Extraction | Dry options (Loewer-compatible) |

✅ Applications:

Laser cut parts post-processing

Plasma-cut / oxyfuel-cut deslagging

Edge rounding for paint/powder coating prep

Oxide film removal (stainless/mild steel)

Graining decorative surfaces

Punched and waterjet-cut part smoothing

1. Processing Scope

Applicable Materials: Stainless steel, carbon steel, aluminum plates, copper plates, and various non-ferrous metals.

Functions:

The MSP-L800 is a dry-type machine that combines one sanding belt station and four sets of planetary universal abrasive flap brush stations. It is designed for:

Deburring edges and holes

Achieving surface finishing: brushing, oxide scale removal, polishing

It removes burrs produced by stamping, shearing, laser cutting, plasma cutting, and flame cutting in a single pass. All edges and holes are evenly rounded (small R angle), ensuring safe, high-quality parts.

2. Working Principle

A sanding belt station removes heavy slag and large burrs from the surface.

Followed by 4 flap brush heads, each pair rotating in opposite directions while revolving as a group. These create high-speed centrifugal forces for grinding, scraping, trimming, and polishing edges and holes.

Results in 0.2–0.5 mm R-radius edges, without affecting part dimensions.

Each station can work independently:

Sanding belt only: Brushed surface finishing, oxide removal, and deslagging.

Brushes only: 360° deburring, ideal for laser-cut or CNC-punched film-covered sheet metal—burrs removed without damaging the protective film or surface.

3. Advantages

High productivity: Continuous feed system supports high-volume orders.

Superior consistency: Automated surface treatment greatly outperforms manual deburring.

Lower cost: Much lower cost per unit area than manual processing.

Safe & eco-friendly: Equipped with wet-type dust collector, reduces fire risk, filters metal powder, and provides a clean work environment.

4. Technical Specifications

| Parameter | Value |

| Max. working width | ≤800 mm |

| Thickness range | 0.5 – 80 mm |

| Minimum part size | 50 mm × 50 mm (for solid/non-perforated parts) |

| Total machine power | 30.25 kW (excluding dust collector) |

| Sanding belt size | Φ1910 mm × 800 mm |

| Brush size | Φ300 mm × 300 mm |

| Feed speed | 0.5 – 6 m/min (VFD adjustable) |

| Sanding belt line speed | ~18 m/s |

| Brush self-rotation speed | 8 – 26 m/s (VFD adjustable) |

| Brush planetary speed | 1 – 15 rpm (VFD adjustable) |

| Planetary axis heads | 1 planetary, 4 self-rotating |

| Servo thickness control | 0.01 mm precision |

| Brush compensation accuracy | 0.01 mm servo-adjusted |

| Abrasive media | Sanding belt + flap brush |

| Dust extraction capacity | 4000 m³/h |

| Machine size (L×W×H) | 2650 mm × 1650 mm × 2150 mm |

| Machine weight | Approx. 2.2 tons |

5. Component & Brand List

| Component | Specification / Model |

| Sanding contact drum | Φ150 mm × 800 mm |

| Sanding belt motor | 7.5 kW |

| Brush rotation motor | 4 kW |

| Brush planetary reducer motor | 750 W |

| Brush lift servo motor | 750 W |

| Conveyor belt | Φ5380 mm × 800 mm |

| Conveyor drive motor | 1.5 kW |

| Conveyor reducer | Hypoid RV75 |

| Worktable lift servo motor | 750 W |

| Belt tracking sensor | — |

| Belt tensioning cylinder | ACQ80×30 |

| Belt correction cylinder | SDA63×5 |

| Brush rotation inverter | 4 kW |

| Brush planetary inverter | 0.75 kW |

| Conveyor inverter | 1.5 kW |

| Vacuum fan inverter | 15 kW |

| Vacuum suction fan | 15 kW |

| Bearings | High-speed |

| Low-voltage electricals | — |

| PLC control system | — |

| Touchscreen display | 7-inch |

6. Installation Requirements

Installation space: At least 4 m × 3.5 m

Power supply: 380V, 50Hz ±10%

Compressed air: Clean and stable compressed air source