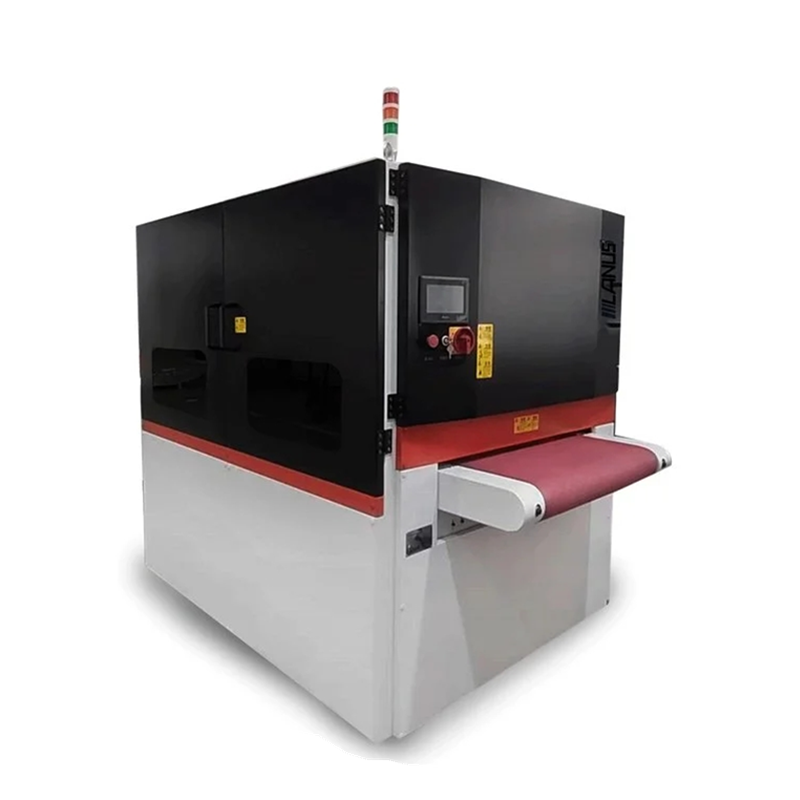

800mm Sheet Metal Deburring Machine – 3 Working Stations

Configuration: Abrasive Belt + Flap Wheel + Abrasive Belt

For Precision Deburring, Edge Rounding & Surface Finishing

Product Overview

This 800mm deburring machine is designed with a powerful three-station configuration:

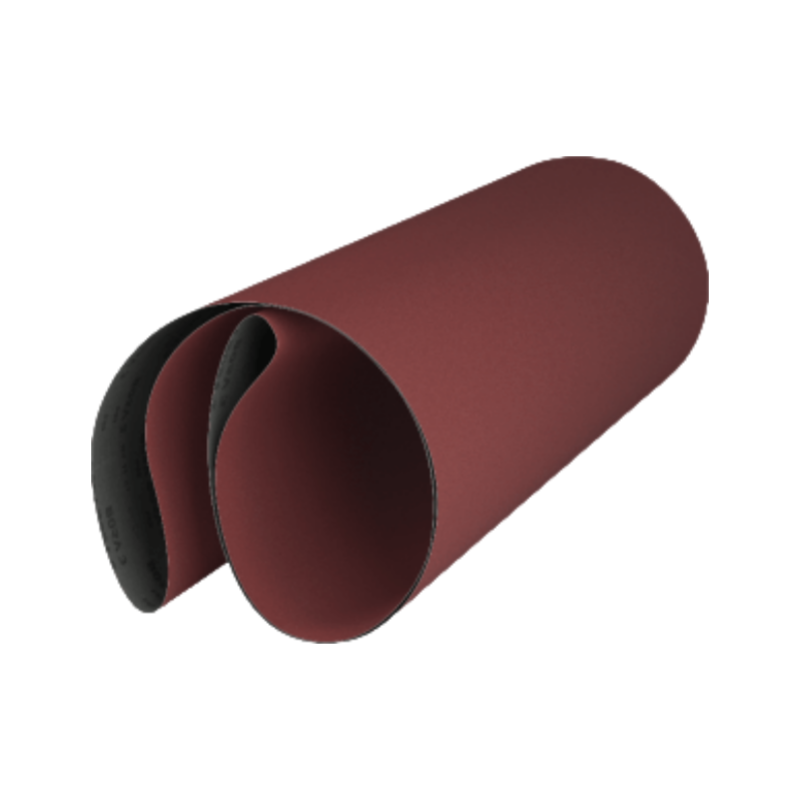

First Abrasive Belt – Heavy burr and slag removal

Flap Wheel (Rotary Brush) – Edge rounding and surface smoothing

Second Abrasive Belt – Final finishing or brushing

It is ideal for sheet metal parts made from carbon steel, stainless steel, aluminum, copper, etc., particularly those processed by laser cutting, plasma cutting, punching, or shearing.

⚙️ Key Features

Working Width: Up to 800mm

Working Thickness: 0.5–80mm adjustable

Three-Stage Process: Burr removal → Edge rounding → Finishing

Flap Wheel Station: Creates consistent R rounding and improves surface for painting/coating

Dust Extraction Ports: Ready for external collector

HMI Touchscreen (Optional): For recipe saving and auto-adjustments

⚙️ Frequency-Controlled Motors: Adjustable brush and belt speeds

Safety Interlocks and emergency stop system

Technical Specifications

| Item | Spec |

| Max Working Width | 800mm |

| Min Part Size | 50mm x 50mm |

| Processing Thickness | 0.5 – 80mm |

| First Belt Size | Ø1910mm × 800mm |

| Flap Wheel Size | Ø300mm × 300mm |

| Second Belt Size | Ø1910mm × 800mm |

| Feed Speed | 0.5 – 6 m/min (adjustable) |

| Brush Speed | 500 – 1400 rpm (frequency controlled) |

| Dust Extraction Volume | ≥ 5000 m³/h |

| Power Supply | ~36.5 kW total (depending on options) |

| Machine Dimensions | Approx. 3050 × 2150 × 2150 mm |

| Weight | ~3000 kg |

✅ Applications

Laser/Plasma-Cut Part Deburring

Precision Edge Rounding Before Coating

Slag Removal & Surface Finishing

Hole Edge Smoothing and Inner Edge Cleanup

Uniform R-Radius Edge Creation for Safety & Coating