Welds and bonding in powertrain components must meet strict quality standards. To obtain first-class performance, the joint surface must be thoroughly cleaned. The laser is an efficient cleaning tool that can remove all traces of residual grease.

Components may be contaminated by drawing lubricants or cooling lubricants and anti-rust oils used during the manufacturing process. These residues are usually not visible, but they can severely reduce the quality of the subsequent high-energy bonding or bonding process. Especially in the highly automated manufacturing environment of the automotive industry and its suppliers, the standards of component quality and reliability have been improving. Now surface contamination detection has become an indispensable link in the production process.

Traditional cleaning methods are time-consuming, cannot be automated, and often have harmful effects on the environment. At the same time, there is no reliable way to measure the cleaning effect. In accordance with standards such as VDA19 and the corresponding ISO guidelines, a unified inspection procedure for particulate contamination of automotive functional components has been established. Recently, more attention to liquid contamination has made laser cleaning the protagonist. The pulsed laser can quickly evaporate the residual liquid in the target area, the effect is measurable, repeatable, and the process is environmentally friendly and can be automated.

● Cleanliness improves reliability

In the production of large gear components, laser welding has become a popular choice because of its low energy requirements and thus can reduce deformation. A large number of components in the automotive powertrain must meet strict quality standards. They are made of different materials and alloys. It is difficult or impossible to weld using traditional technology.

● Powerful laser, shorter cycle

Automobile manufacturers need a fast, automated way to thoroughly clean up surface residues to obtain strong, void-free and micro-crack welding and bonding. Laser cleaning systems, especially those using pulsed solid-state lasers, can meet all these requirements. The main factors that determine the choice of laser are the required cleanliness and the cycle time for cleaning the components.

● Reach the designated location quickly and efficiently

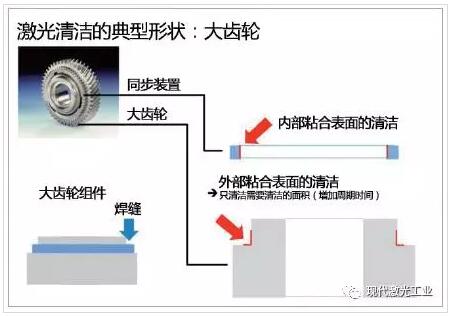

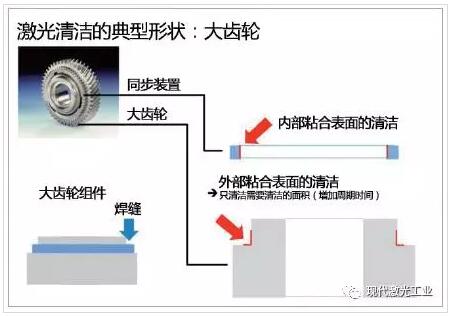

In a highly automated, high-volume production process, time is of the essence. Unlike traditional cleaning methods that require immersing the entire component in a solvent or using abrasives or thermal shock technology, laser cleaning can be performed on specific functional surfaces (such as welds and bonding, which are usually no more than a few square millimeters in size).

The time required for cleaning depends on the time required for laser welding, generally between 4-10 seconds. Another advantage of selective cleaning is that it eliminates the need to transport components from the cleaning station to the production line. The cleaning laser is integrated on the production line, just upstream of the welding or bonding station.

● Clean edges and corners

To clean a specific surface, the scanner optics causes the laser beam to move quickly back and forth on the workpiece. Different scanning patterns and speeds can be used according to the required cleaning effect. Linear scanning motion can be used to clean light pollution; if deeper cleaning is required, overlapping circular scanning motions can be used (similar to the action of an electric toothbrush). In this case, the laser pulse passes through the same point multiple times to enhance the cleaning action.

Typical laser cleaning application: Quickly remove the residue adhering to the surface of the transmission component. (Picture: TRUMPF GmbH + Co. KG)

The laser can also "clean round corners" without repositioning the workpiece. Place a mirror to guide the laser beam to clean the upper and lower surfaces of the tubular or contoured component at the same time.

● Only clean the areas that need to be cleaned

The laser can clean extremely sensitive surfaces, such as aluminum, carbon fiber composites or coated parts, without damaging the underlying materials. Or, by selecting different parameter groups, the same laser can also roughen the surface and improve the strength of the bond. The flexibility of laser tools allows them to be applied to various tasks required. TRUMPF determines the laser power and pulse frequency suitable for various applications based on the principle of "not exceeding the necessary limit, as little as possible". This method can bring benefits to customers because the cost of laser cleaning is about five times lower than that of comparable wet chemical cleaning processes.

● Is it clean enough?

At present, standards and guidelines for inspection procedures for particulate contamination have been established. It can be expected that these standards and guidelines will cover liquid contamination sooner or later. Therefore, it is not only a question of which cleaning method is suitable, but also the effect must be verified and recorded. This is why TRUMPF is cooperating with SITA Messtechnik GmbH.

The use of scanning optics can achieve different cleaning effects by changing the scanning method. If a part of the light beam is reflected by a mirror, the upper and lower surfaces of the component can even be cleaned at the same time without repositioning the workpiece. (Picture: TRUMPF GmbH + Co. KG).

The company is located in Dresden and develops, produces and sells process measurement and control equipment for applications such as component cleanliness monitoring. SITA has developed a fluorescence test equipment that can determine the operating parameters of the laser cleaning system based on the task undertaken. By irradiating ultraviolet rays on the components, the traces of fluorescent organic substances (such as lubricants, oils, coolants or solvents) are displayed. The non-contact sensor measures the degree of residual contamination, or confirms that the cleaned surface is completely free of residuals. Unlike traditional inspection methods that use test inks, SITA equipment can also provide accurate results for very small test surfaces.

● Another cleaning option

"Cleaning" not only means that the effect of laser processing is very clean, but the processing process itself is also a green process. Unlike wet chemical processes, it does not use toxic solvents and avoids the noise generated by the use of abrasive methods. In addition, laser cleaning is very gentle, and the process speed is obviously faster than other methods. These advantages have been recognized by the automotive industry, and other industries are currently following up, because the laser is a multi-purpose cleaning tool.

Pulsed lasers can be used to selectively clean bonding surfaces or small objects (such as ancient coins), while UV lasers are very suitable for cleaning large components. They can be used to remove liquid residues on CFRP components, or by setting other parameters, they can help remove stubborn paint or rust layers. As a high-tech cleaning tool, laser has great potential.