Preface

Compared with traditional welding, laser welding has the advantages of small heat input and thermal influence, large aspect ratio, and automatic welding process. Aluminum alloy has light weight, good toughness, high yield ratio and easy processing and forming. It is widely used in welding structure products such as containers, machinery, electric power, chemical industry, aviation, aerospace, etc. The use of aluminum alloy instead of steel plate welding can greatly reduce Structural quality. Aluminum is a more active metal with low ionization energy and high thermal conductivity. It is easy to form a refractory Al2O3 film on the surface. It is easy to form defects such as unfusion, pores, inclusions, and thermal cracks in the weld, which reduces the mechanical properties of the welded joint. . Compared with argon tungsten arc welding or melting argon arc welding, laser welding has narrow weld seams, small heat-affected zones, reduced overlap joints, precise controllable welding process, and automation. At present, laser welding is mainly used for thin-walled electronic components, structural parts, aerospace parts, etc. The research on 10,000-watt fiber lasers for deep penetration welding of large and thick plates is the future development trend.

1 Aluminum alloy classification and weldability

Aluminum and aluminum alloys can be divided into 1000 series (industrial pure aluminum), 2000 series (Al-Cu series), 3000 series (Al-Mn series), 4000 series (Al-Si), 5000 series (Al-Mg), 6000 series Series (Al-Mg-Si) and 7000 series (Al-Zn-Mg-Cu). According to the characteristics of the process, aluminum alloys can be divided into deformed aluminum alloys and cast aluminum alloys. Among them, deformed aluminum alloys are divided into two categories: non-heat-treated strengthened aluminum alloys and heat-treated strengthened aluminum alloys.

Different aluminum alloys have different welding properties. For example, non-heat-treated aluminum and aluminum alloys 1000 series, 3000 series and 5000 series have good weldability. 4000 series alloys have very low crack sensitivity. For 5000 series alloys, when ω (Mg) =2%, the alloy cracks, as the magnesium content increases, the welding performance is improved, but the ductility and corrosion resistance become worse. The 2000 series, 6000 series and 7000 series alloys have a higher tendency of hot cracking, poor welding seam formation, and significantly reduced aging hardness after welding.

To sum up, for aluminum alloy welding, appropriate process measures must be adopted, and the welding method and filler material must be correctly selected to obtain a good welded joint. Surface treatment of the material before welding, use organic solvents to remove oily dirt, and then immerse in NaOH solution, rinse the surface with running water, and then perform photochemical treatment. The processed weldment is within 24 hours Conduct welding process experiments.

2 Main problems existing in laser welding of aluminum alloy

Laser welding uses laser as a high-energy-density light source. It has the characteristics of fast heating and instantaneous solidification. The aspect ratio is as high as 12:1. However, due to the high reflectivity and good thermal conductivity of aluminum alloy, as well as the shielding effect of plasma, when welding Some defects will inevitably appear, among which the two most important defects are pores and thermal cracks. Due to the strong reflection of aluminum alloy to laser, the first problem encountered in aluminum alloy laser welding is how to effectively improve the material's absorption of laser light. Based on some characteristics of aluminum alloy itself, the laser welding process is more complicated, and it is urgent to improve and perfect.

2.1 Laser absorption rate

The higher the absorption rate of the material to the laser, or the smaller the heat transfer coefficient or temperature conductivity, the easier the laser energy is absorbed by the surface of the material, the surface temperature rises rapidly, and the material melts or evaporates.

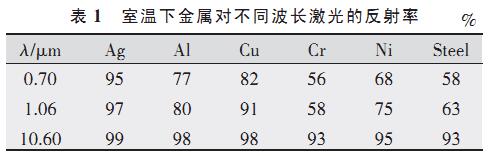

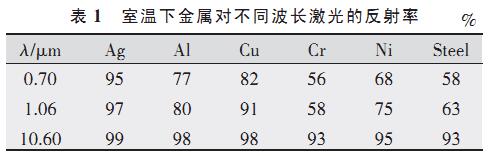

The reflectivity of various metals to lasers with different wavelengths is shown in Table 1. The reflectivity of various metals decreases as the wavelength becomes shorter, and the reflectivity of Ag, Al, and Cu to lasers is as high as 90%, which undoubtedly increases the laser Difficulties in processing At room temperature, the absorption rate of CO2 laser by aluminum alloy is extremely low, 98% of the laser energy will be reflected by the aluminum alloy surface, and the reflectivity of Nd:YAG laser is also 80%. It can be seen that aluminum alloy has the characteristics of high reflectivity to laser light and low absorptivity. This is because the density of free electrons in aluminum alloy is very large. Under the strong vibration of light wave electromagnetic wave, strong reflected wave and weak transmission wave are generated. The reflected wave is not easily absorbed by the surface of aluminum alloy. High reflectivity.

2.2 Induction and stabilization of "small holes"

In the laser welding process, when the laser energy density is greater than 3.5*10^6W/cm2, ions will be generated. The welding method is carried out by deep penetration welding. The principle is mainly the "small hole" effect. The appearance of the "small hole" can be greatly improved. Improve the absorption rate of the material to the laser, and the weldment is fused at high energy density to obtain a good welding effect. The primary problem in the laser welding of aluminum alloy is the difficulty of inducing and maintaining the stability of the pinhole, which is due to the aluminum alloy itself. Characteristics and optical characteristics of the laser beam. As mentioned earlier, Al at room temperature can reflect 80% of the energy. Coupled with its good thermal conductivity, a large laser energy density threshold is required to produce "small holes". There is such a threshold in laser welding of different aluminum alloys. Once the input power is greater than this value, the transfer of laser energy into the material is no longer restricted by heat conduction. The welding is carried out by deep penetration welding, and the laser radiation will cause the base metal to be strong. Evaporate and form an evaporation groove. The laser beam penetrates into the material through the evaporation groove, and the weld depth and welding efficiency also increase sharply. For highly reflective materials, such as aluminum alloys and copper alloys, a very large power density is required during welding. This requires certain welding models and the selection of collimating focusing mirrors.

2.3 Mechanical properties of weld

Refinement strengthening, solid solution strengthening, and aging precipitation strengthening are several strengthening mechanisms of aluminum alloys. Even with these strengthening mechanisms, the large amount of evaporation of low melting point alloy elements such as Mg and Zn during the laser welding process will also cause the weld to sink. The hardness and strength decrease. During the instantaneous solidification process, after the fine-grained strengthened structure is transformed into the as-cast structure, its hardness and strength will decrease. In addition, the presence of cracks and pores in the weld leads to a decrease in tensile strength. In short, the problem of joint softening is another problem in laser welding of aluminum alloys.

2.4 Stoma

Aluminum alloys are prone to pores in the laser welding process. There are two main types: hydrogen pores and pores caused by keyhole bursting.

(1) Hydrogen hole. Aluminum alloy is very easy to form oxide film on the surface at high temperature, and the oxide film is easy to absorb moisture in the environment. When heated by a laser, water is decomposed to produce hydrogen, and the solubility of hydrogen in liquid aluminum is about 20 times that of solid aluminum. During the instantaneous solidification of the alloy, the solubility of hydrogen decreases sharply when it changes from liquid aluminum to a solid state. If the excess hydrogen in the liquid aluminum cannot smoothly rise and overflow, it will form hydrogen pores. Such pores are generally regular in shape, larger in size than dendrites, and dendritic crystal solidification patterns can be seen on the inner surface.

(2) The keyhole collapsed. The internal gravity and atmospheric pressure of the welding hole are in equilibrium. Once the balance is broken, the liquid metal in the molten pool cannot flow over and fill in time and form irregular holes. Studies have found that the magnesium content of the inner wall of the hole is about 4% of that near the weld. Times.

Because the cooling rate of laser welding is too fast, the hydrogen gas hole problem is more serious, and there are more holes caused by the collapse of small holes in laser welding.

2.5 Thermal cracking

Aluminum alloy is a typical eutectic alloy, and it is prone to hot cracks during welding, including weld crystallization cracks and HAZ liquefaction cracks. Usually crystalline cracks appear in the weld zone, and liquefaction cracks appear in the near-joint zone. Among aluminum alloys, the 6000 series Al-Mg-Si alloys are especially sensitive to cracks. The base metal has undergone rapid heating and cooling. During the instantaneous solidification and crystallization process, due to the large degree of undercooling, the crystal grains are along the center of the vertical weld. Directional growth, forming Al-Si or Mg-Si, Al-Mg2Si and other low-melting eutectic compounds at the columnar crystal boundary, weakening the bonding force of the crystal planes, and easy to produce crystal cracks under the action of thermal stress. In the aluminum alloy welding process, such as some low-boiling elements (Mg, Zn, Mn, Si, etc.) are easy to evaporate and burn. The slower the welding speed, the more serious the burn, which changes the chemical composition of the weld metal. Due to the segregation of components in the weld zone, eutectic segregation will occur and grain boundary melting will occur, and liquefaction cracks will be formed at the grain boundary under stress, which will reduce the performance of the welded joint.

3 Aluminum alloy laser welding process

In order to realize the laser welding of aluminum alloy and solve the above-mentioned problems, it is mainly solved from the following aspects at present.

3.1 Gas protection device

The factor that has the greatest influence on the loss of low melting point elements in aluminum alloy is the pressure when the gas is sprayed from the nozzle. By reducing the nozzle diameter, increasing the gas pressure and flow rate can reduce the burning loss of Mg, Zn, etc. during the welding process, and it can also Increase penetration. There are two blowing methods, direct blowing and side blowing. You can also blow up and down the weldment at the same time. The blowing method can be selected according to the actual situation during welding.

3.2 Surface treatment

Aluminum alloy has a high reaction to laser. Appropriate surface pretreatment of aluminum alloy, such as anodic oxidation, electrolytic polishing, sandblasting, sandblasting, etc., can significantly increase the absorption of beam energy on the surface. Studies have shown that the tendency of aluminum alloys to crystallize cracks after the oxide film is removed is greater than that of the original aluminum alloys. In order not to damage the surface state of the aluminum alloy, but also to simplify the laser welding engineering process, the pre-welding method can be used to increase the surface temperature of the workpiece to increase the material's absorption rate of the laser.

3.3 Laser parameters

Welding lasers are divided into pulsed lasers and continuous lasers. When the wavelength of pulsed lasers is 1064nm, the beam is particularly concentrated, and the pulse single point energy is larger than that of continuous lasers. However, the energy of pulsed lasers generally does not exceed, so thin-wall weldments are generally suitable.

3.3.1 Pulse mode welding

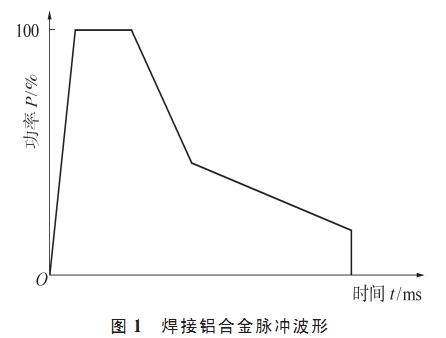

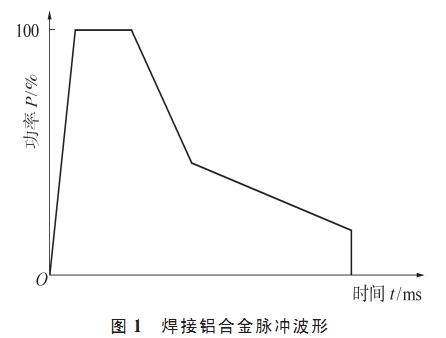

The appropriate welding waveform should be selected during laser welding. Commonly used pulse waveforms include square wave, spike wave, double peak wave, etc. Usually, the time of a pulse wave is in milliseconds. During a laser pulse, the reflectivity of the metal changes greatly. . The reflectivity of the aluminum alloy surface to light is too high. When a high-intensity laser beam hits the surface of the material, 60%-98% of the laser energy on the metal surface will be lost due to reflection, and the reflectivity changes with the surface temperature. Therefore, the best choice for welding aluminum alloy is sharp wave (see Figure 1) and double peak wave. The rising stage of the waveform is to provide greater energy to melt the aluminum alloy. Once the "small hole" in the workpiece is formed, deep penetration begins. During welding, the absorption rate of the liquid metal to the laser increases rapidly after the metal is melted. At this time, the laser energy should be quickly reduced, and the welding should be performed with a low power to avoid splashing. The slow-down part of the welding waveform has a longer pulse width, which can effectively reduce the occurrence of pores and cracks. Using this waveform, the welding seam is melted and solidified repeatedly to reduce the solidification rate of the molten pool. This waveform can be adjusted appropriately when welding samples of different types.

Choosing a proper defocus amount can also reduce the generation of pores. The change of the defocus amount has a great impact on the surface formation and penetration of the weld. The use of negative defocus can increase the penetration, while in pulse welding, the positive defocus Scorching will make the weld surface smoother and more beautiful.

Due to the high reflectivity of the aluminum alloy to the laser, in order to prevent the vertical reflection of the laser beam from the vertical incidence and damage the laser focusing lens, the welding head is usually deflected to a certain angle during the welding process. The diameter of the solder joint and the effective joint surface increase with the increase of the laser tilt angle. When the laser tilt angle is 40°, the largest solder joint and effective joint surface are obtained. The weld penetration depth and effective penetration depth decrease with the laser tilt angle. When it is greater than 60°, the effective weld penetration depth drops to zero. Therefore, tilting the welding head to a certain angle can appropriately increase the weld penetration depth and penetration width.

In addition, when aluminum alloy laser welding, the faster the welding speed, the more likely it is to crack. Because the welding speed is too fast and the degree of undercooling is large, the grains in the weld zone are refined, and a large number of "beam crystals" growing in the same direction are formed, which is conducive to the generation of cracks on the crystal plane between the beam crystals. If the welding speed is too fast, the penetration depth of the weldment becomes relatively small.

3.3.2 Continuous mode welding

Embrittlement or even cracks may occur when using traditional laser welding. Because the heating process of continuous laser welding is not like a pulse machine, the crack tendency is not obvious during welding. Most aluminum alloys welded by fiber lasers will not be brittle. There is a certain degree of toughness after welding, and the advantages are obvious.

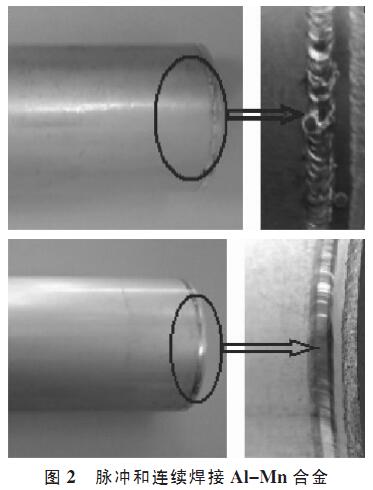

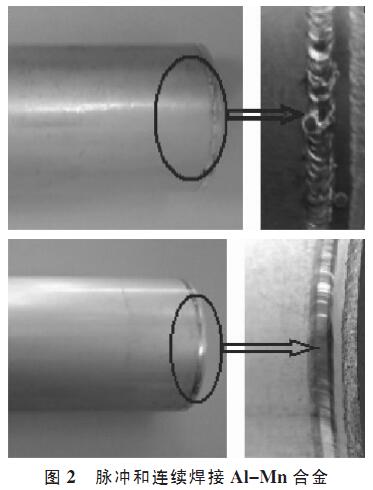

Industrial pure aluminum can be welded well with pulse laser welding, and there will be no cracks after welding. However, in some industries, the surface after welding needs to be polished, and there will be dents after laser pulse welding, and the amount of polishing will increase, which increases the processing Cycle and production costs, and continuous lasers can solve these problems. Figure 2 shows the comparison of the welding seam of the battery shell after pulse laser welding and continuous laser welding. It can be seen from Figure 2 that the impulse solder joints are uneven, undercut, and the surface is dented, spattered, and the strength after welding is not high. In order to improve the quality of the weld seam, continuous laser welding is used. The weld seam surface is smooth and uniform, free of spatter and defect, and no cracks are found in the weld seam.

Arc craters are prone to appear during argon arc welding, and laser welding is the same. Small craters are prone to appear at the end. This can be improved by gradual and gradual exit during welding, that is, a slow rise and slow fall stage is set in the waveform; in addition, it can be used for welding. Properly increase the welding rate to avoid small pits.

In the welding of aluminum alloys, the advantages of continuous lasers are obvious. Compared with traditional welding methods, the production efficiency is high and there is no need to fill wires. Compared with pulsed laser welding, it can solve the defects generated after welding, such as cracks, pores, and splashes. Etc., to ensure that the aluminum alloy has good mechanical properties after welding; there will be no dents after welding, and the amount of polishing and grinding after welding is reduced, saving production costs. However, because the continuous laser spot is relatively small, the assembly accuracy of the workpiece is higher.

3.5 Introduction of alloying elements

Preventing the occurrence of hot cracks is one of the key technologies for laser welding of aluminum alloys. 6000 series alloys are very sensitive to cracks. When ω(Mg2Si) =1%, hot cracks will appear. It can be improved by adding suitable alloying elements to adjust the chemical composition of the molten pool, such as adding Al-Si or Al-Mg -Si powder has certain advantages in reducing cracks. In addition, wire feeding can be used to improve the welding effect and obtain a uniform weld. The hardness of the weld is also increased. The content of Mg and Si in the dendrite in the fusion zone increases due to the increase in the concentration of the filler material. Increase the strength of the joint. Usually 6063 and 6082 aluminum alloys are filled with Al-5Si and Al-7Si welding wires, 6013 and 6056 plates are welded with CO2 and Nd: YAG lasers, respectively, and Al-12Si welding wires are filled.

3.6 Other process methods

In view of the stability of the aluminum alloy laser welding process and the quality of the weld, the current research hotspot of aluminum alloy laser welding is the use of composite technology, that is, the high energy density of the laser and the larger heating range of the arc are coupled to give full play to the two heat sources. Its own advantages, combined with high energy density beam quality and stable arc characteristics, complement each other. For high-reflective materials such as aluminum alloy, laser hybrid welding can preheat or melt the surface of the material by arc energy, which greatly improves the absorption of laser energy by aluminum alloy. T. Shida et al. used a 10 kW CO2 laser combined with TIG and MIG arcs to weld aluminum alloys. The introduction of arcs greatly improved the utilization of laser energy.

rate, the weld penetration ratio is also increased by 5%-20%, and the weld surface is smooth and well formed. Laser hybrid welding increases the geometric size of the molten pool through the coupling of the laser beam and the arc, and changes the flow conditions of the material in the molten state, which is beneficial to the elimination of pores.

Dual-beam welding of aluminum alloy is also a way to eliminate air holes. A 6 kW continuous fiber laser was used to perform dual-beam butt welding of 5052 aluminum alloy. The two-beam parallel and serial welding modes and welding at different welding speeds were studied. The study of seam morphology and structure found that there are large holes in the welds welded in parallel with dual beams, and welding aluminum alloys in series can obtain good weld formation without porosity.