Analysis of technology terms for hand-held fiber laser welding machine

Laser welding is an efficient and precise welding method that uses a high-energy-density laser beam as a heat source. Laser welding is one of the important aspects of the application of laser material processing technology. Laser welding can be realized by continuous or pulsed laser beam. The principle of laser welding can be divided into heat conduction welding and laser deep penetration welding.

Laser welding is non-contact welding. No pressure is required during the operation, but inert gas is required to prevent oxidation of the molten pool. Filler metal is occasionally used. Laser welding can be combined with MIG welding to form laser MIG hybrid welding to achieve large penetration welding, and at the same time, the heat input is greatly reduced compared with MIG welding.

So, what are the process parameters of the handheld fiber laser welding machine in actual use? Today, the editor of Lixing Laser will tell you some common process parameters involved in laser welding machines.

Process term analysis of hand-held fiber laser welding machine:

The first laser beam in the world was produced by using a flash bulb to excite ruby crystal grains in 1960. Due to the limitation of the heat capacity of the crystal, it can only produce a very short pulse beam and the frequency is very low. Although the instantaneous pulse peak energy can be as high as 10^6 watts, it is still a low energy output.

The laser beam of the laser welding machine is easy to focus, align and be guided by optical instruments. It can be placed at an appropriate distance from the workpiece and can be re-guided between the tools or obstacles around the workpiece. Other welding rules are subject to the above-mentioned space Limited and unable to play; the laser beam can be focused on a small area, and small and closely spaced parts can be welded.

The laser welding machine can reduce the heat input to the minimum required amount in actual use, the metallographic change range of the heat-affected zone is small, and the deformation caused by heat conduction is also the lowest; no electrode is required, and there is no concern about electrode contamination or damage . And because it is not a contact welding process, the wear and deformation of the equipment can be minimized; it is easy to automate high-speed welding, and it can also be controlled by digital or computer; it is not affected by magnetic fields (arc welding and electron beam welding are easy), It can accurately align the weldment; no vacuum or X-ray protection is required; if the through-hole welding is used, the depth-to-width ratio of the weld bead can reach 10:1.

In actual use of the laser welding machine, the workpiece can be placed in a closed space (vacuumed or the internal gas environment is under control); a wide range of weldable materials can also be joined to each other with various heterogeneous materials; thin materials or thin diameters can be welded When using wire, it will not be as easy to be troublesome as arc welding; it can weld two kinds of metals with different physical properties (such as different resistances); it can switch the device to transmit the laser beam to multiple workstations.

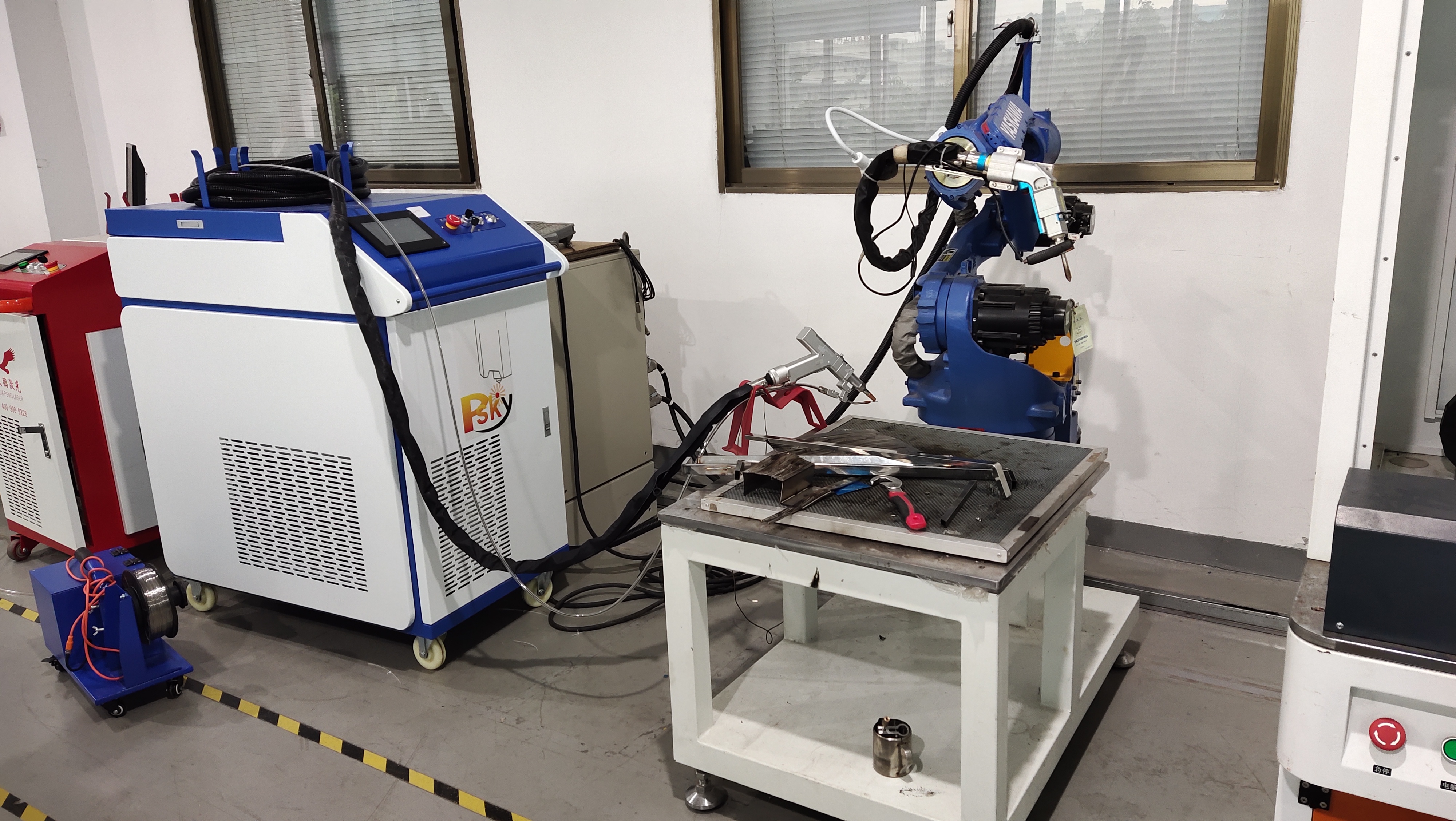

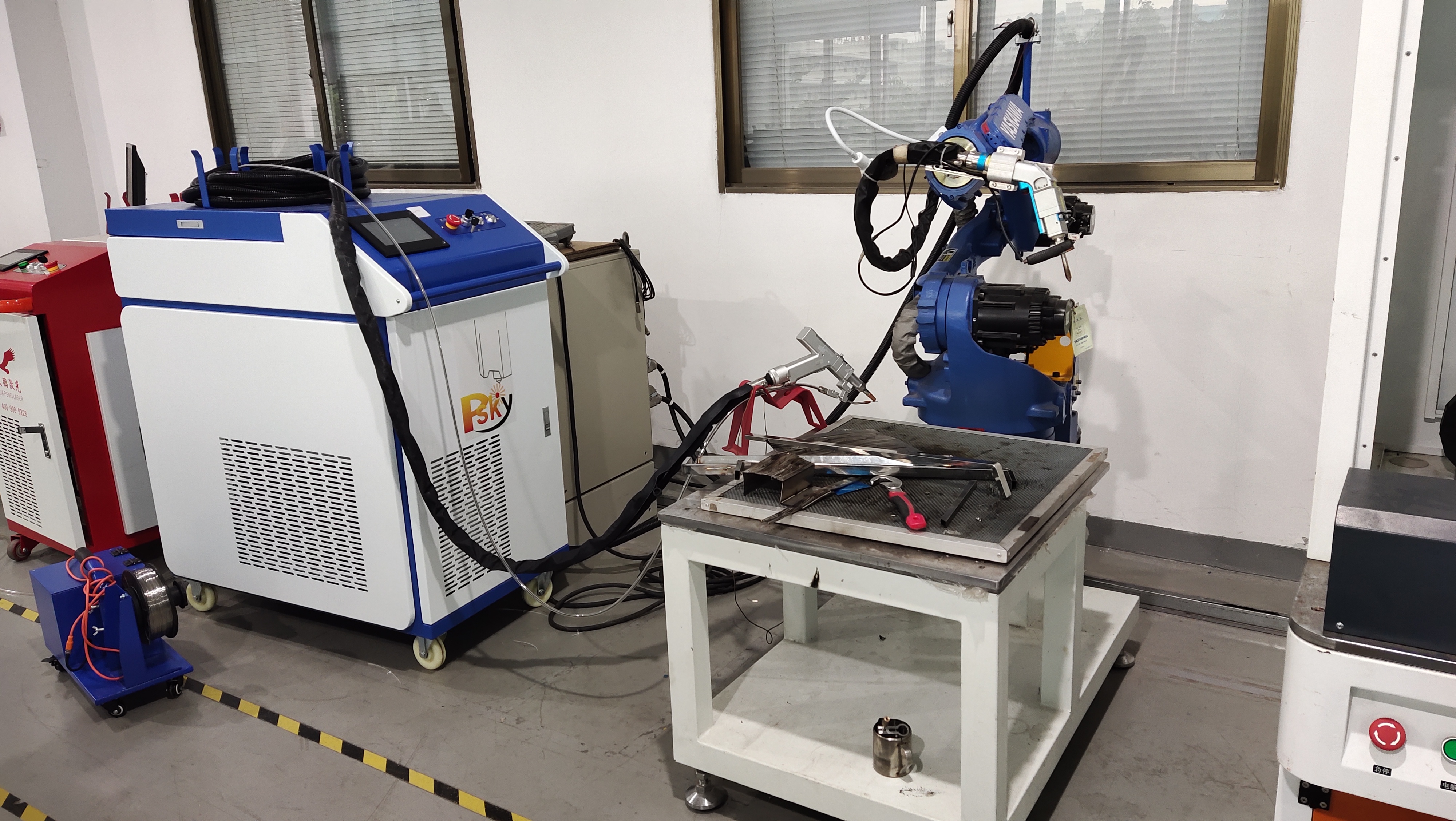

Advantages of Lixing Laser Welding Machine: 2~10 times the speed, easy to operate, good welding effect, flexible and convenient, fast welding speed, 2-10 times faster than traditional welding operations, a machine can save 2 welding when young. The operation is simple, you can start after simple training, you need a job certificate, and you can weld beautiful products without a master; the basic requirements of the operator are low, the recruitment is easy, and the cost of the staff is low.

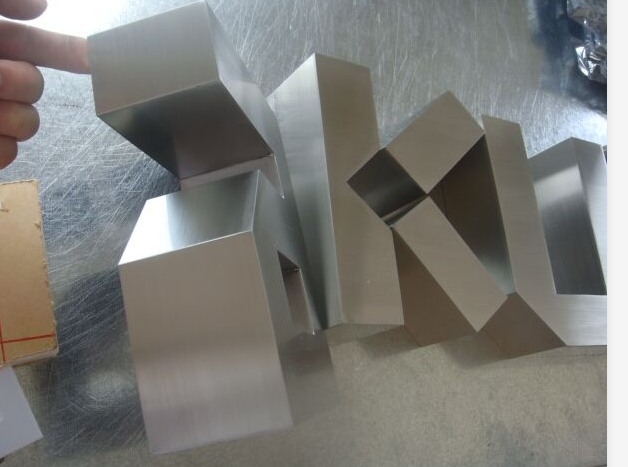

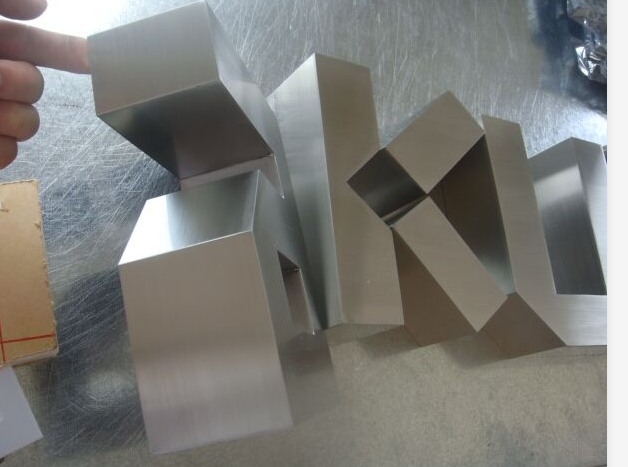

Optional swing welding head, welding compound degree, can weld wider welding seam, outer and tailor welding effect is good, welding seam is smooth and beautiful, reducing subsequent polishing sequence, saving time and cost; welding parts are deformed, welding scars, and welding is firm. Body design (laser, cooling machine, welding system integrated in the body), integration, the system is more stable; the volume of the whole machine, with casters, foot cups, can move easily, adapt to various working occasions, can adjust the position of the machine at any time and then set up the working environment Into the welding operation.

Analysis of technical terms of laser welding machine:

1. Laser pulse waveform and width

The laser pulse waveform is an important issue in laser welding, especially for sheet welding. When a high-intensity laser beam hits the surface of the material, 60~98% of the laser energy will be reflected and lost on the metal surface, and the reflectivity changes with the surface temperature. During a laser pulse, the reflectivity of the metal changes greatly. Pulse width is one of the important parameters of pulsed laser welding. It is not only an important parameter different from material removal and material melting, but also a key parameter that determines the cost and volume of processing equipment.

2. Laser power density, welding speed

Power density is one of the most critical parameters in laser processing. With a higher power density, the surface layer can be heated to the boiling point within a microsecond time range, resulting in a large amount of vaporization. Therefore, high power density is beneficial for material removal processing, such as punching, cutting, and engraving. For lower power densities, it takes several milliseconds for the surface temperature to reach the boiling point. Before the surface layer vaporizes, the bottom layer reaches the melting point, which makes it easy to form a good fusion weld. Therefore, in conductive laser welding, the power density is in the range of 10^4~10^6W/CM^2.

The speed of the welding speed will affect the heat input per unit time. If the welding speed is too slow, the heat input will be too large, causing the workpiece to burn through. If the welding speed is too fast, the heat input will be too small and the workpiece will not be welded through.

3. The influence of defocusing amount on welding quality

Laser welding usually requires a certain amount of defocus, because the power density in the center of the spot at the laser focal point is too high and it is easy to evaporate into a hole. On each plane away from the laser focus, the power density distribution is relatively uniform. There are two defocusing methods: positive defocus and negative defocus. If the focal plane is above the workpiece, it is a positive defocus, otherwise it is a negative defocus. When the defocus is negative, a greater penetration depth can be obtained, which is related to the formation process of the molten pool. At the same time, the high concentration of vapor causes the liquid metal to move to the edge of the molten pool, forming a depression in the center of the molten pool. When the defocus is negative, the internal power density of the material is higher than that of the surface, and it is easy to form stronger melting and vaporization, so that the light energy can be transmitted to the deeper part of the material. Therefore, in practical applications, when the penetration depth is required to be large, negative defocus is used; when welding thin materials, positive defocus should be used.