| Model | MSP-L800 | Example model |

| Primary Process | Deburring, Edge Rounding, Oxide Removal |

|

| Compatible Materials | Mild Steel, Stainless Steel, Aluminum |

|

| Max. Material Thickness | 0 - 80 mm | Capacity for thin sheet to thick plate. |

| Max. Material Width | 800 mm | Standard processing width. |

| Min. Part Dimensions | 50 x 50 mm | Minimum processable part size. |

| Max. Material Weight | 350 kg | Maximum weight capacity per part. |

| Conveyor Speed | 0.6 - 4.0 m/min | Infinitely variable for process adjustment. |

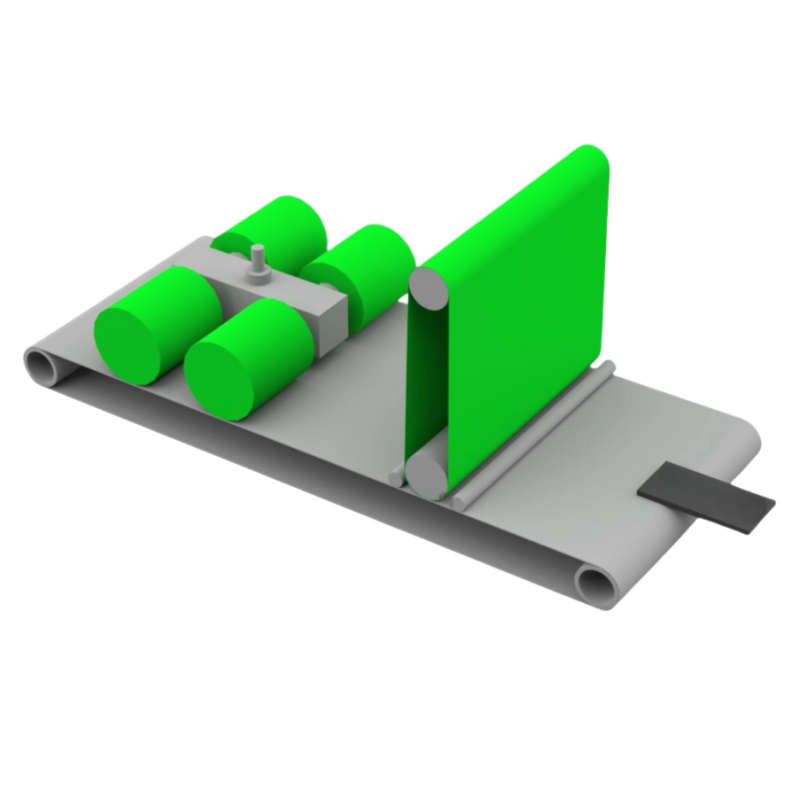

| Abrasive System | Combination: Abrasive Belt + Flap Wheels | Belt for heavy burr removal, flaps for fine rounding. |

| Flap Wheels | 4 x Ø300 x 300 mm | Quantity, Diameter, and Length. |

| Tool Working Height | 120 mm |

|

| Power Consumption | 16.8 kW / 22.8 kW | Typical operating power / Peak power. |

| Holder/Conveyor System | Magnetic (Vacuum Optional) | Standard magnetic for ferrous metals; vacuum for alloys. |

| Min. Deduster Requirement | 3000 m³/h | Minimum air volume for effective dust extraction. |

| Compressed Air Requirement | 5.0 Bar (Min) | Required pressure for pneumatic systems and optional vacuum. |

| Machine Weight | ~2500 kg | Approximate net weight of the machine. |

| Control System | PLC (Programmable Logic Controller) | For automated, user-friendly operation and parameter storage. |

| Warranty | 1-2 Years | Varies by manufacturer. 16 |