FEATURES AT A GLANCE

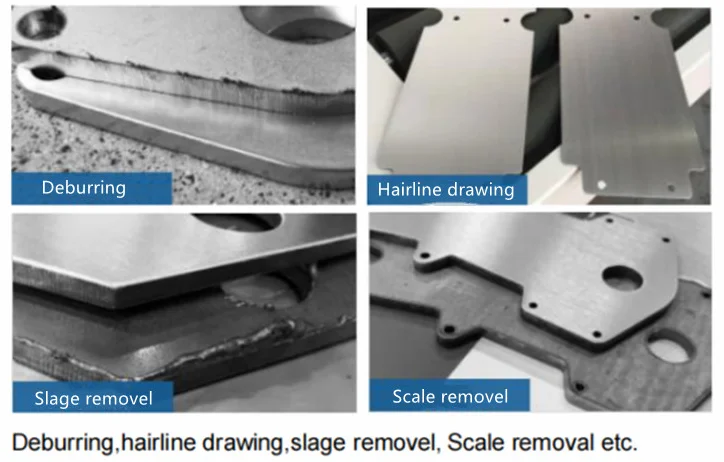

The deburring machine, also known as the metal sanding machine, as the name suggests, is used to treat burrs on rough material surfaces. In the general mechanical industry, deburring machine equipment is mostly used. In the past, some metal materials relied on manual grinding, which had low efficiency and low cleanliness. The Linus deburring machine was developed to solve this pain point. The Linus deburring machine is divided into slag deburring, universal rolling brush deburring, and metal deburring Double sided deburring, etc.

Mainly used for deburring precision grinding of workpieces, removing burrs from small gaps, etc., it is widely used for deburring precision stamping parts, gear parts, automotive parts, powder metallurgy parts, aviation, mechanical processing parts, etc., mainly for deburring hanging slag, chamfering, etc.

So what are the main industries in which it is applied?

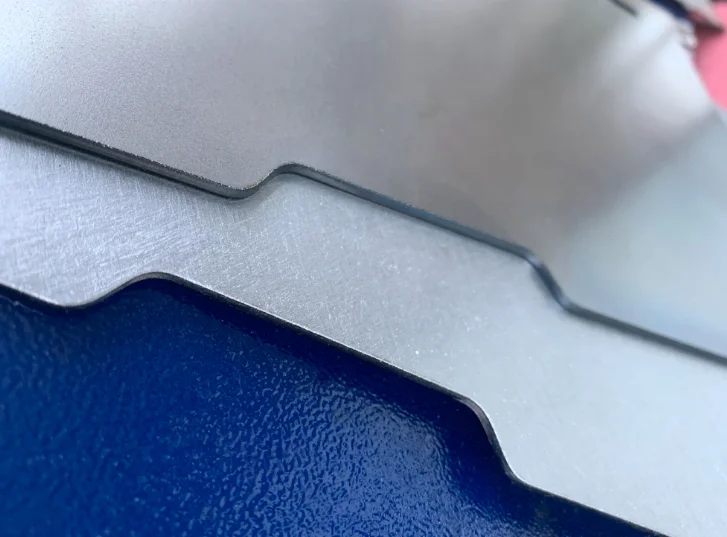

1、 Precision sheet metal manufacturing

Fully automatic deburring machine equipment is often used for the deburring of various precision parts. For consumables after laser cutting, burrs are inevitably generated at the edges. This makes it easy for the deburring machine to remove these burrs and improve efficiency.

2、 Automotive precision components

In the field of automotive parts production, various parts are often produced, such as aluminum wheels, frequency converter shells or bearing covers, cylinder bodies, valve bodies, etc., which also have burrs. Using an automatic deburring machine can easily remove all burrs, ensuring that they are not affected in use.

3、 Processing of special materials such as aerospace and nuclear power

Special materials such as aerospace and nuclear power may have burrs during production and processing, which can cause different hazards. For example, in the aerospace industry, some temperature electromagnetic relay equipment may experience electromagnetic structure jamming due to burrs falling off, resulting in severe consequences. 2. Some shaft workpieces with burrs can cause severe damage to the sealing ring gasket, leading to sealing damage and failure. 3. The mechanical and electrical product accessories did not undergo surface smoothness manufacturing before electroplating, which had a negative impact on the adsorption force of the electroplated coating. Therefore, these burrs must be removed on the issue, and the Hangzhou Xiangsheng fully automatic deburring machine can effectively solve these deburring problems.

4、 Medical equipment

In the production process of medical devices, all semi-finished parts also need to be processed using an automatic deburring machine. Regardless of the burrs in any part, they can be completely removed without leaving any marks under the use of the automatic deburring machine.

5、 Processing of medium and thick plates in engineering and agricultural machinery

After the production of engineering and agricultural machinery parts, there will be long burrs or peaks left. Abnormal sharp manual operations not only have low efficiency but also a high accident rate. Using an automatic deburring machine can solve all problems and quickly remove all burrs, burrs, or peaks, improving product quality and reducing the occurrence of defective products.

| No | Item | RWX600 | RWX800 | RWX1000 |

| 1 | Power | 22.97KW | 22.97 | 29.92 |

| 2 | Working width | 630mm | 800mm | 1000mm |

| 3 | Weight | 1800kg | 2000kg | 2500kg |

| 4 | Feeding speed | Frequency Control | Frequency Control | Frequency Control |

| 5 | System | PLC | PLC | PLC |

RD

Abrasive belt and rotary disk,do surface polishing and deburring.burring in hole and edge.

RP

One or multi abrasive belt and polishing spindle, do NO.4 finish and surface buffing,Scotch-Brushed finishing.

WX\RB

Abrasive belt and universal brush,do surface descaling and edge rounding,hole deburring.