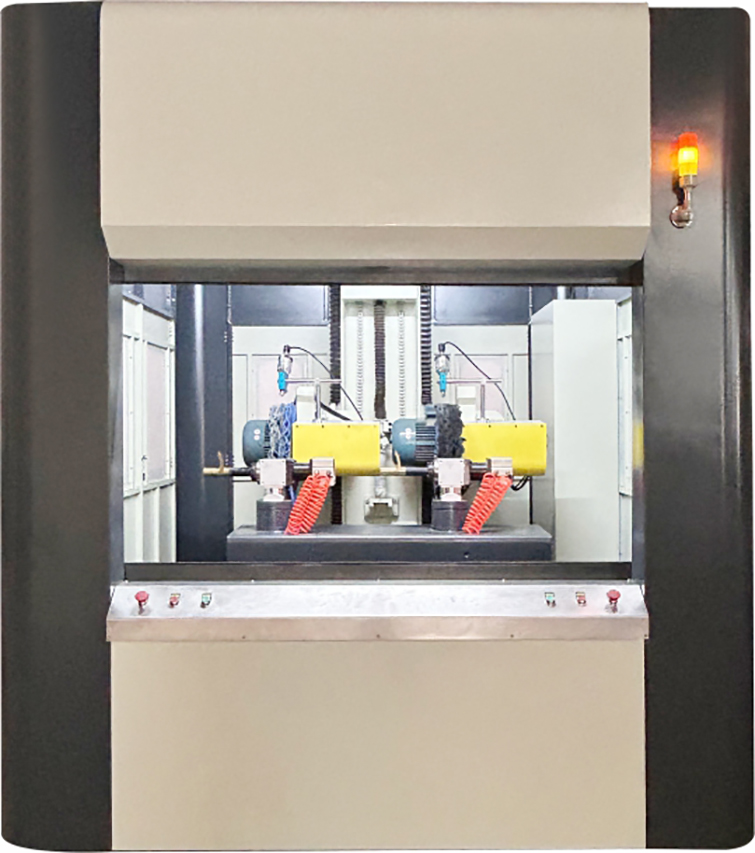

CNC Industrial Buffing Polishing Machine for Sanitary Faucets and Bathroom Accessories: High-Quality Finishing

Overview:

A CNC Industrial Buffing and Polishing Machine is specially designed to deliver high-precision surface finishing for sanitary faucets and bathroom accessories, ensuring exceptional quality and efficiency. These machines utilize advanced CNC control systems for automated processes, providing uniformity and consistent finishing for complex designs and delicate materials.

Key Features:

High Precision Buffing:

Achieves a mirror-like finish on brass, stainless steel, and other materials.

Handles intricate contours and complex shapes, ideal for faucets and bathroom fixtures.

CNC-Controlled Process:

Multi-functional Capabilities:

Supports buffing, polishing, grinding, and deburring in a single machine.

Adaptable to various shapes, such as spouts, levers, escutcheons, and more.

Durability and Efficiency:

Advanced Tooling Options:

Applications:

Sanitary Faucets:

Polishing faucet spouts, levers, and handles.

Ensures smooth edges and flawless surfaces.

Bathroom Accessories:

Buffing and polishing towel racks, soap dispensers, and shower heads.

Perfect for decorative elements requiring uniformity and gloss.

Other Related Products:

Benefits:

Consistent Quality:

Time-Saving:

Cost-Effective:

Environmentally Friendly:

Process Workflow:

Material Loading:

Deburring:

Belt Grinding:

Buffing and Polishing:

Inspection: