Dapeng 200w 400w Dual Pulse YAG Automatic Stainless Steel Gold Laser Spot Welding Machine

| Model | DPH-200DH-YAG-W | DPH-400DH-YAG-W |

| Laser source type | Fiber source | Fiber source |

| Laser Out Power | 200W | 400W |

| Laser wavelength | 1064nm

| 1064nm |

| Laser Source

| YAG

| YAG |

| Focal spot diameter

| 0.2mm

| 0.2mm |

| Monitoring system(CCD) | 20 times HD surveillance | 20 times HD surveillance |

| Laser frequency

| 1-50Hz

| 1-50Hz |

| Repeatability | ±0.01mm | ±0.01mm

|

| Machine operating temperature | 0~40℃ | 0~40℃ |

| Electricity demand | 220V/380V

| 220V/380V

|

| Cooling method | Water Chiller Hanli

| Water Chiller Hanli

|

| Continuous operating time | 24 hours | 24 hours |

| Weight | 200kg | 200kg

|

| Dimensions | 520*1180*1180mm

| 520*1180*1180mm

|

Features:

1. The penetration ratio is large, the deformation is small, the solder joints are non-polluting, the welding is non-porous, the appearance is flat and beautiful, and there is no need or simple post-processing;

2. The output power of the laser is stable, the operation process of the equipment is stable and reliable, and the processing consistency is high;

3. Corrosion resistance, high temperature resistance, high photoelectric conversion efficiency;

4. Laser energy, pulse width and frequency are adjustable, suitable for welding various metals;

5. Fast speed, high efficiency, large depth, small heat affected area, high welding quality, no contamination of welding points,high efficiency and environmental protection.

Specification:

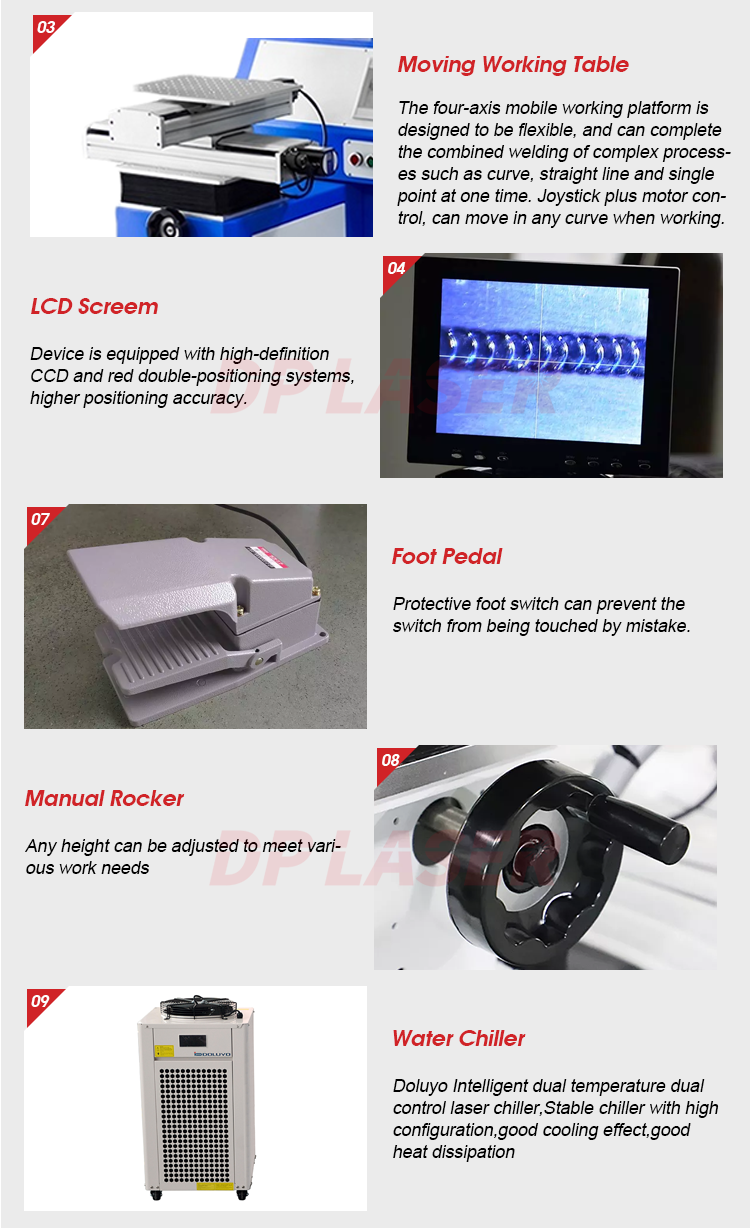

1. Mainly composed of laser, power supply and control, cooling machine, light guiding and focusing, and binocular reflection microscopic observation, compact structure and small volume.

2. The micro-coordinate indication coaxial with the laser beam makes the workpiece positioning easy and does not require special fixtures.

3. Laser power, pulse frequency, and pulse width can be preset and changed through the control panel.

4. The power supply adopts the drawer structure and is easy to remove. Therefore, the equipment is easy to operate and maintain,does not need to be filled with solder, has high welding speed, reliable joints, small deformation of the workpiece and beautiful appearance.

5. The key components such as ceramic laser cavity adopt the products of internationally renowned manufacturers to ensure the high reliability and high performance of the equipment.

5. The unique YAG crystal cooling method improves the beam quality and the life of the xenon lamp, reducing the cost of use.

Application:

The equipment can weld gold, silver, platinum, titanium and its alloys, electric nickel belt and other materials.

It can be used for precision welding of jewelry, watch hairspring, integrated circuit leads, various tiny heat sensitive parts,

suitable for optoelectronic devices, electronics, communication. , machinery, automotive, military, gold jewelry and other

industries. Machine features:

* Non-contact operation methods can meet the requirements of clean and environmental protection;

* Machining workpieces with laser welding machine can improve work efficiency, the finished workpiece has beautiful appearance, small weld seam, large welding depth and high welding quality;

* Real-time energy negative feedback ensures that the laser output energy is stable, and the output energy can be arbitrarily set according to the welding material and shape.

Application range:

It is suitable for a wide range of applications in aviation, aerospace, automotive, power battery, machinery manufacturing, shipbuilding, chemical industry and daily necessities.

Product advantages:

• The penetration ratio is large, the deformation is small, the solder joints are non-polluting, the welding is non-porous, the appearance is flat and beautiful, and it is not necessary or simple to process.

• The output power of the laser is stable, the equipment operation process is stable and reliable, and the processing consistency is high;

• With the flange forming equipment, the whole coil steel plate can be automatically welded into a steel pipe on a high-speed production line;

• The quality of the welding can be detected online, and the welding defects that may occur during the welding process are issued in time for re-welding in time to avoid the occurrence of the broken belt.