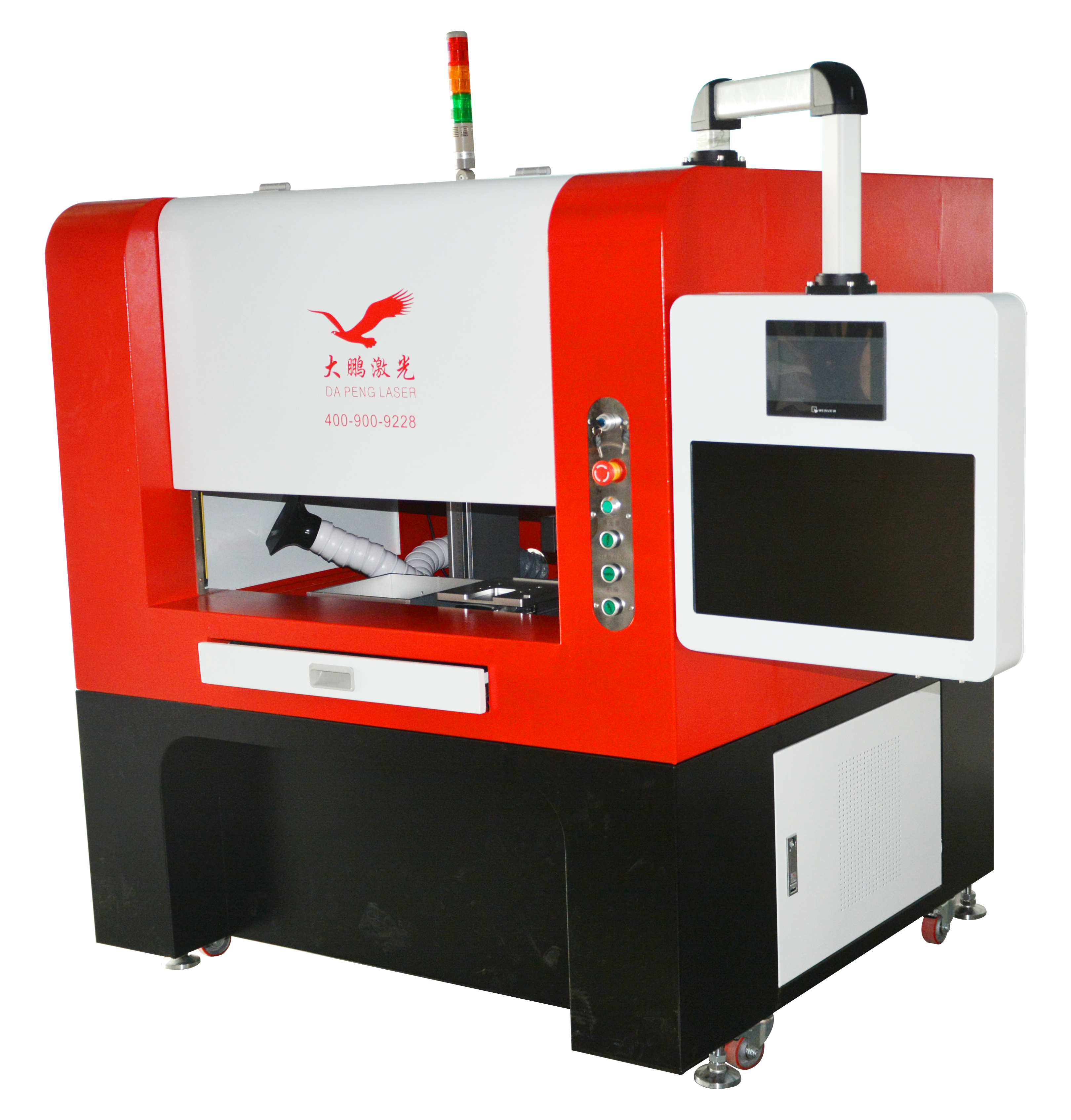

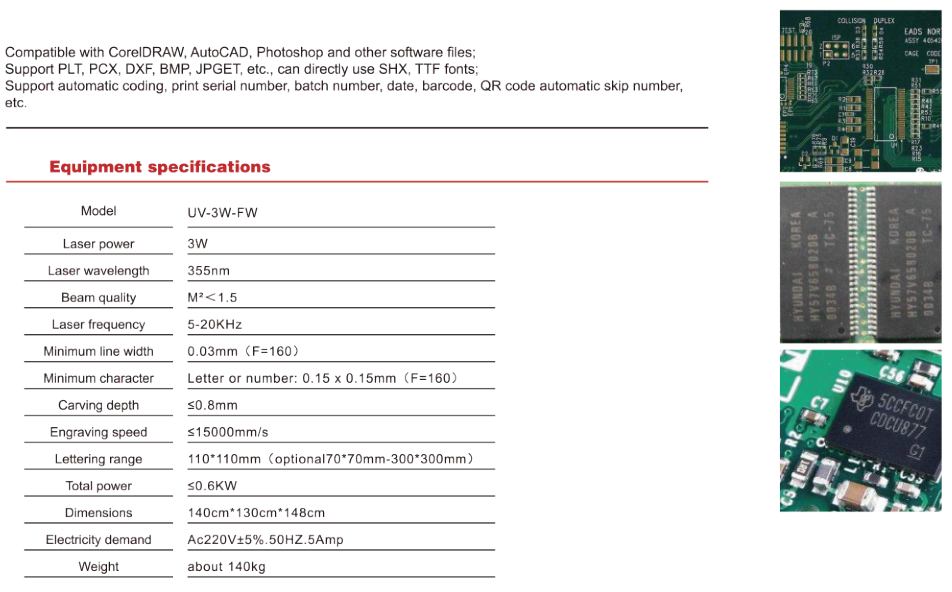

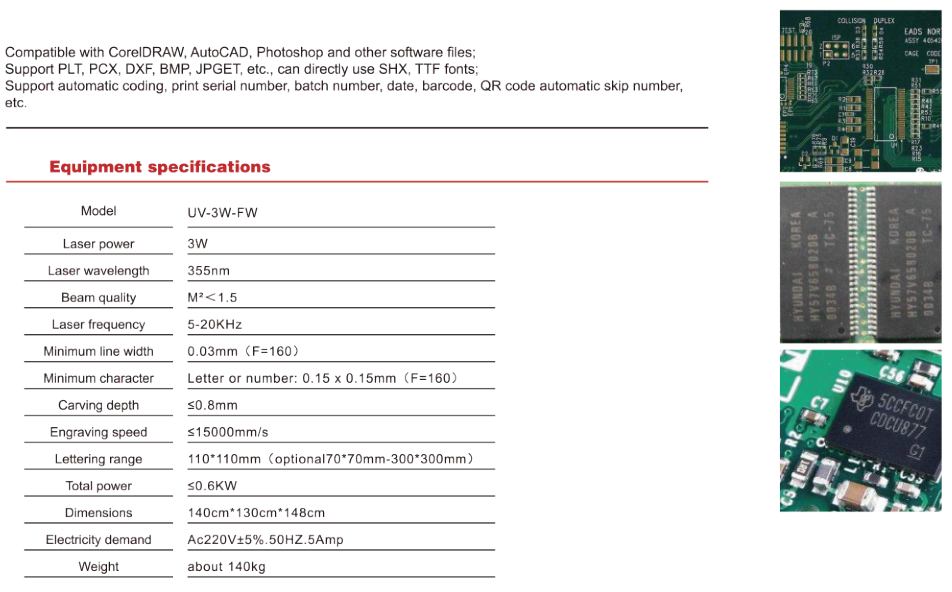

Circuit board (ultraviolet) laser engraving machine

Compatible with CorelDRAW, AutoCAD, Photoshop and other software files;

Support PLT, PCX, DXF, BMP, JPGET, etc., can directly use SHX, TTF fonts;

Support automatic coding, print serial number, batch number, date, barcode, QR code automatic skip number, etc.

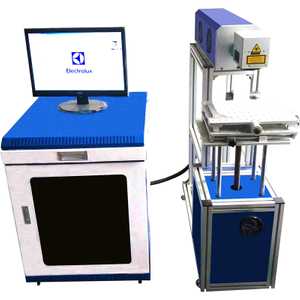

Nameplate automatic laser marking machine

Nameplate automatic loading and unloading marking machine, using Mitsubishi PLC and laser marking card as the motion control part, using Weilun touch screen as the man-machine interface, servo motor wire rod guide rail and cylinder as the actuator; equipment can do intermittent loading , can save labor very much, a working time of about 20-40 minutes (estimated time);

The main workflow is as follows:

Turn the machine back to zero → set the corresponding motion parameters → start the device → wait for the feeding mechanism to feed → the product is in place → the robot arm grabs → the marking station secondary positioning → start marking → marking completion → the robot arm reclaiming Material → repeat the above actions → complete a chat → reset each station → alarm → wait for loading