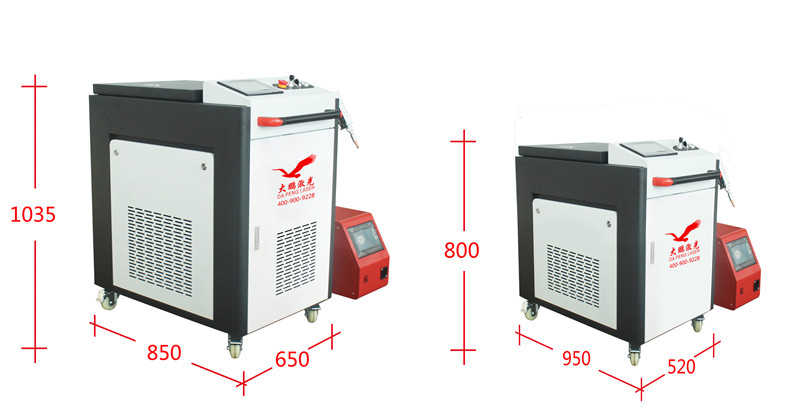

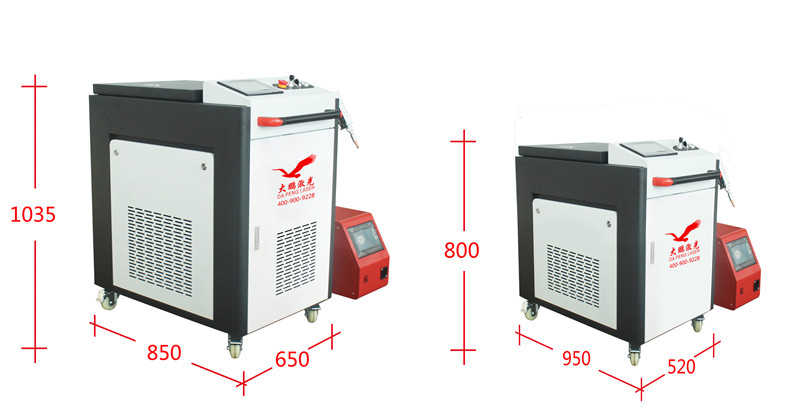

1000W 1500W 2000W Handheld Metal Laser Welders Portable Fiber Laser Weld Welding machine

Handheld laser welding machine is mainly composed of cabinet, robot, control system, water chiller, laser source, welding head and other parts. Through the system control the welding machine to achieve stable, reliable, fast reciprocating movement. The laser welding machine uses continuous fiber laser or continuous fiber laser to accurately control the laser pulse width through digital, energy, repetition frequency and other parameters, so that the workpiece to melt. The formation of a specific pool, enabling the work piece to be laser welding, complete the traditional precision welding process can not be achieved.

1: Simple and easy to earn and handle.

2: The Laser welding does not need mask, only need to wear laser protective glasses;

3: Thewelding seam is smooth and beautiful, needn't do grinding.

4: By controlling the laser energy, the welding part is not deform, or the deformation is very small;

5: Low usage cost, such as power consumption, gas consumption and lens consumption;

6: Opticalfiber up to 10 meters, can be long distance, large workpiece welding;

7: A variety of welding processes, can be spot welding, seam welding, overlap welding;

Features:

1.The energy density is high, the heat input is low, the amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

2.High cooling rate, which can weld fine weld structure and good joint performance.

3.Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly increasing work efficiency.

4.The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

5.No consumables, small size, flexible processing, low operating and maintenance costs.

6.The laser is transmitted through fiber optics and can be used in conjunction with a pipeline or robot.

Application:

This machine is suitable for welding of gold, silver, titanium, nickel, tin, copper, aluminum and other metal and its alloy material, can achieve the same precision welding between metal and dissimilar metals, has been widely used in aerospace equipment, shipbuilding, instrumentation, mechanical and electrical products, automotive and other industries.