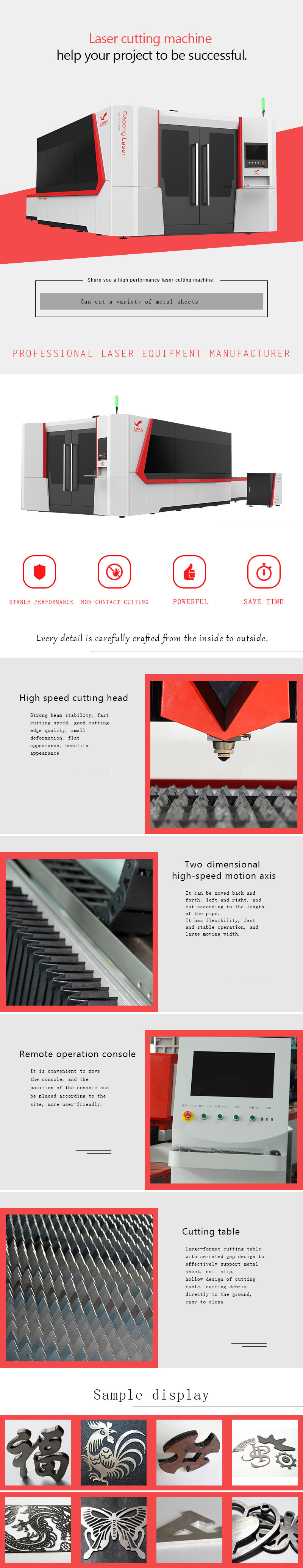

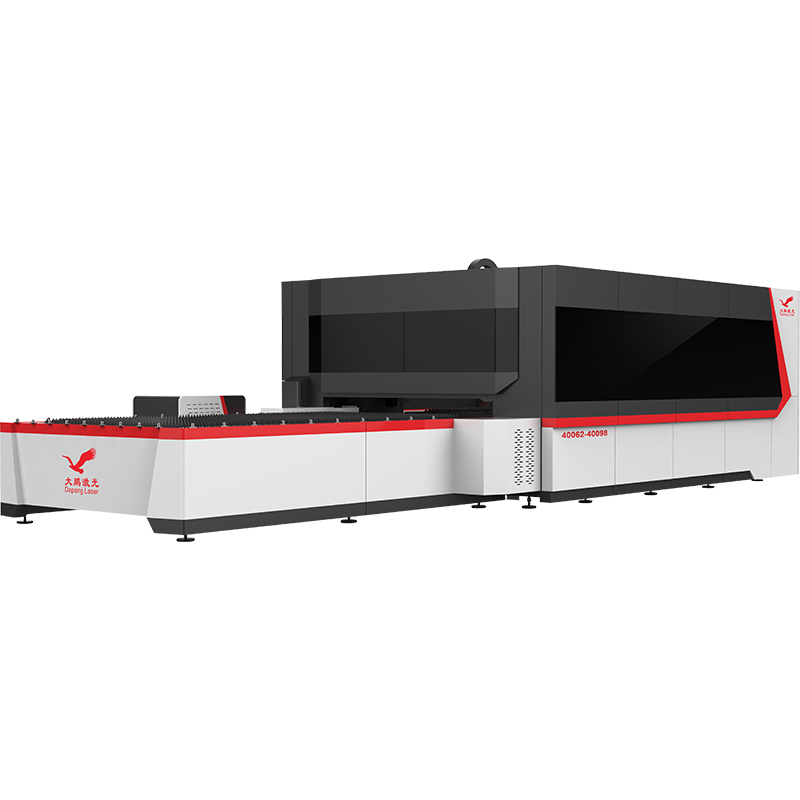

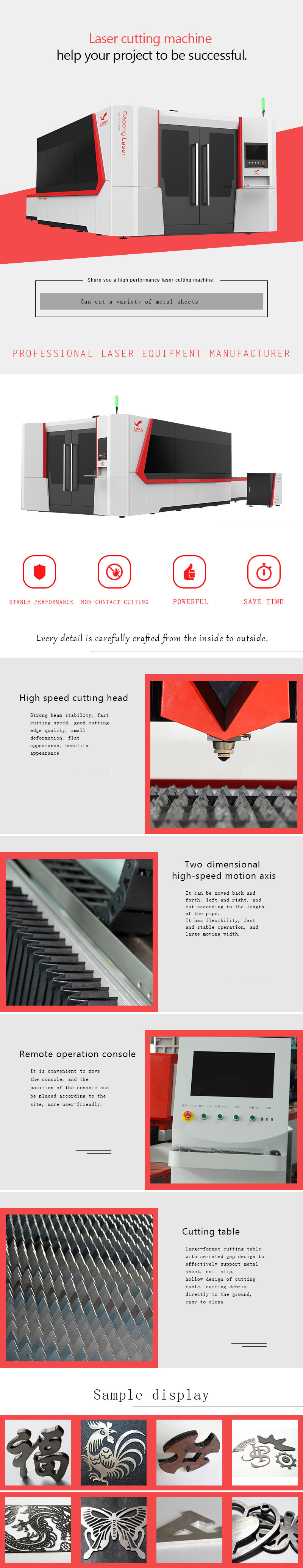

Dapeng Laser High Power 4000W 4020 Large Surrounding Interactive Fiber Laser Cutting Machine Double Platform Large Format High Speed Cutting Large Metal Sheet

Laser source type: Fiber source

Laser Out Power: 1070nm

Laser wavelength: 1000W/2000W/3000W/6000W

Cutting range: 4000×2000mm

Minimum line width: <0.1mm

Transfer method: Precision rack dual drive

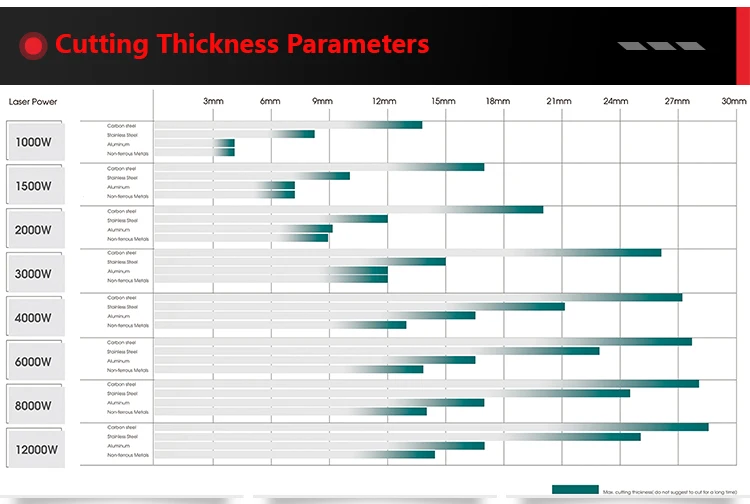

Cutting speed and thickness: Depending on specific material

Repeatability: ±0.02mm

Machine operating temperature: 0~40℃

Electricity demand: 380V/50Hz

Cooling method: Water cooling

Continuous operating time: 24 hours

Maximum operating speed: 120m/min

Maximum acceleration: 0.9G

X/Ypositioning accuracy: 1.2mm

Minimum slit width: 0.15mm

Machine technology:

1. It adopts gantry structure, the whole bed is welded by steel plate box, the whole machine adopts 600 degree high temperature heat treatment, 12 meters gantry milling and finishing, 24 hours cooling with furnace, large gantry milling of guide seat for one processing, good rigidity.

2. The guide rail adopts fully enclosed protection to reduce dust pollution.

3. The double-side rack and pinion drive of the imported servo motor is selected, with high precision, high speed, large torque, large inertia, stable and durable performance, which ensures the high speed and acceleration of the whole machine.

4. The dedicated laser control system has powerful functions, stable operation, man-machine interface, simple operation and easy learning.

5. Germany imported high-precision electronically controlled proportional valve to control the air pressure of the gas used for cutting and paving to achieve better cutting results.

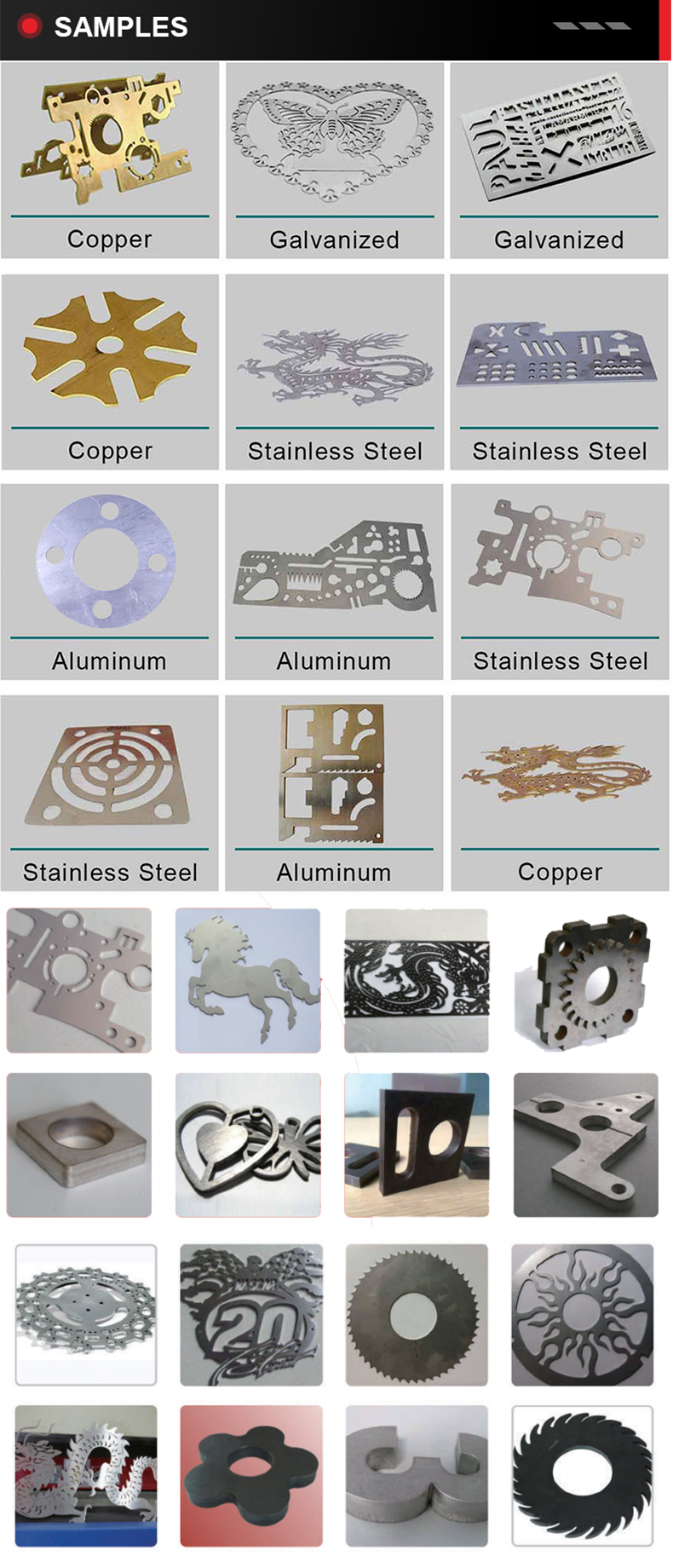

6. Laser processing belongs to non-contact flexible processing, which is not affected by the shape of the workpiece, and can process any graphics.

Machine advantage:

1. One-key exchange of worktables to improve processing efficiency.

2. The cutting work area is surrounded by a large setting to reduce laser radiation.

3. High precision: suitable for cutting precision accessories and fine cutting of various craft words and paintings.

4. Fast speed: 100 times faster than wire cutting.

5. Less thermal influence, not easy to deform. The cutting seam is smooth and beautiful, and no post-processing is required.

6. The price is very high: the price is only 1/3 of the CO2 laser cutting machine of the same performance, and 2/5 of the CNC punching machine of the same power.

7. The use cost is very low: only 1/8-1/10 of the same type of CO2 laser cutting machine, and the hourly cost is only about 18 yuan, while the hourly cost of the CO2 laser cutting machine is about 150-180 yuan.

8. The follow-up maintenance cost is very low: only 1/10-1/15 of the similar CO2 laser cutting machine, and 1/3-1/4 of the same power CNC punching machine.

9. Stable performance to ensure continuous production.

After-sales service:

Dapeng fiber laser cutting machine provides two-year warranty service for the laser, one-year warranty service for the whole machine, and lifetime after-sales service (only the labor fee and the cost of accessories are charged outside the warranty).

Scope of application:

Metal cutting, electrical switch manufacturing, elevator manufacturing, household appliances manufacturing, kitchenware manufacturing, tool processing and other machinery manufacturing and processing industries.

Dapeng Laser's product quality is stable and reliable, and can provide various non-standard automated online laser equipment according to the actual needs of customers. While pursuing product quality, Dapeng Laser also provides customers with efficient, timely and comfortable pre-sale, in-sale and after-sale support and services.