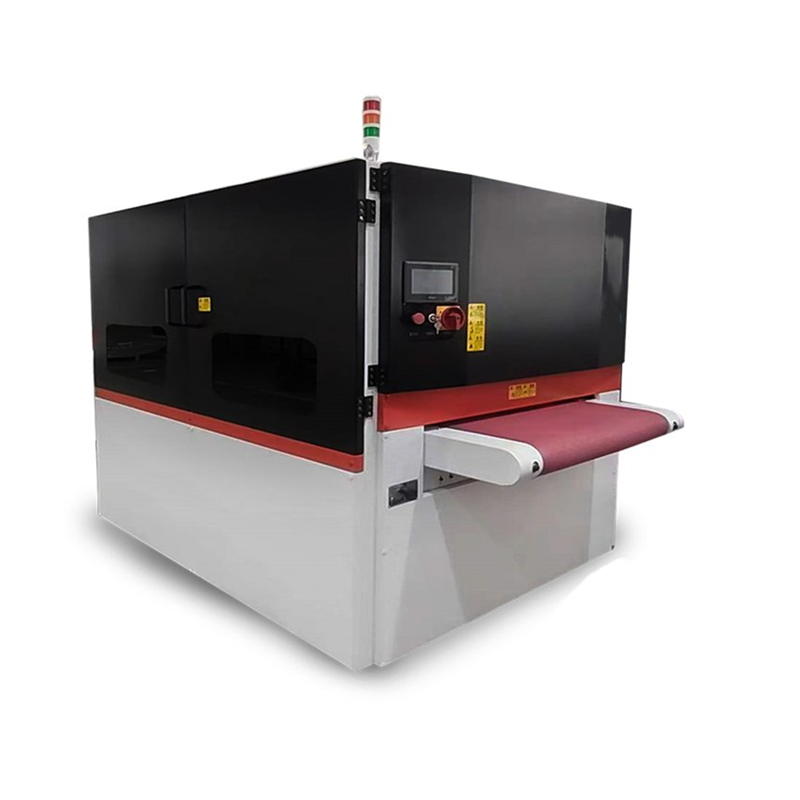

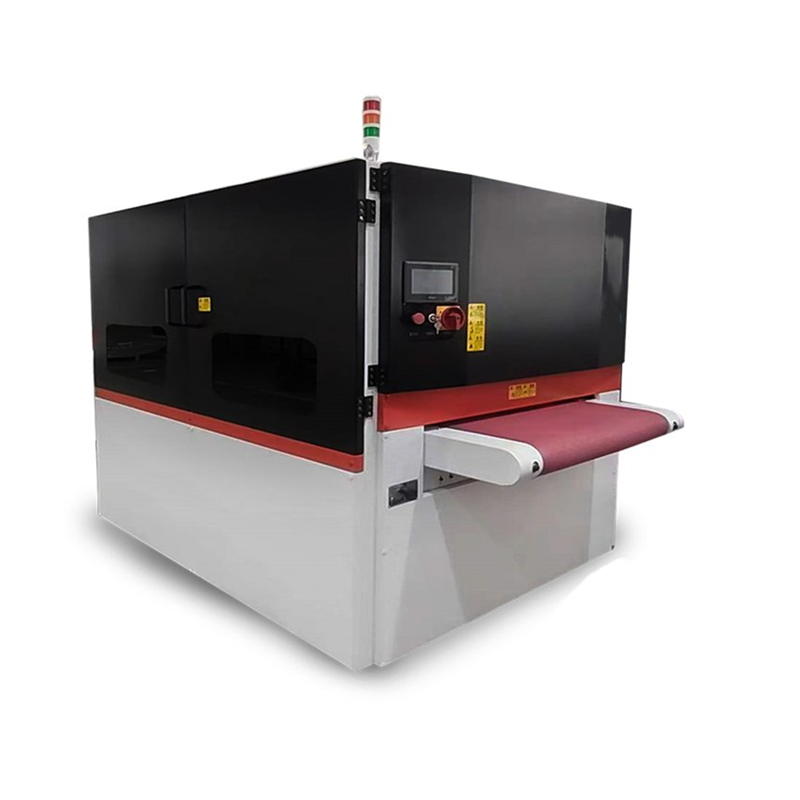

Deburring and Edge Rounding Machine for Metal Parts Processed by Laser Cutting, Punching, and Waterjet Cutting

Detailed Description:

This machine is designed to effectively remove burrs and round the edges of metal parts that have been processed through various cutting methods such as laser cutting, punching, and waterjet cutting. It enhances the quality of the finished products, making them safer, smoother, and ready for further processing. The machine is suitable for a wide range of materials, including steel, aluminum, and stainless steel. Its versatility makes it ideal for industries requiring high-quality surface finishing, such as automotive, aerospace, and manufacturing sectors.

Technical Specifications Table:

| Parameter | Specification |

| Material | Steel, Aluminum, Stainless Steel |

| Process | Deburring, Edge Rounding |

| Material Thickness (mm) | 0 - 80 mm |

| Max. Material Width (mm) | 1000 mm |

| Min. Part Dimensions (mm) | 50 x 50 mm |

| Holder System | Magnetic (Vacuum Optional) |

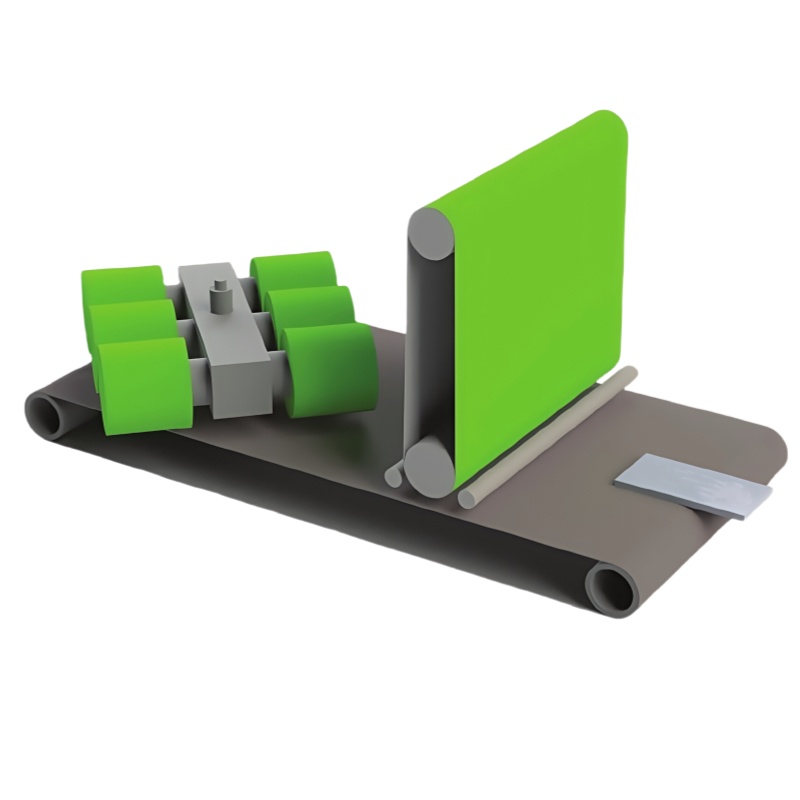

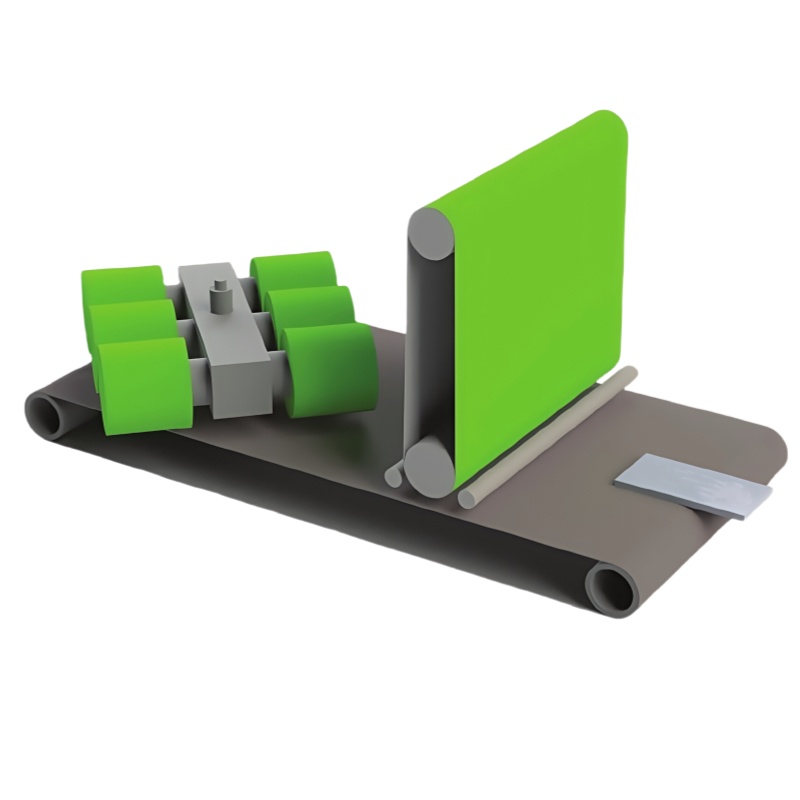

| Flap Wheel Dimensions | 6 pcs, Ø300 x 600 mm |

| Flap Wheel Quantity | 6 |

| Speed | Adjustable |

| Dust Extraction | Yes (Optional) |

| Power | 15-25 kW (depending on model) |

| Feeding Speed | Adjustable (0.5 - 6 m/min) |

Key Features:

Versatile: Capable of deburring and edge rounding a wide variety of metals including steel, aluminum, and stainless steel.

High Efficiency: Suitable for metal parts processed by laser cutting, punching, and waterjet cutting.

Magnetic Holder System: Ensures secure and stable part holding during the deburring process. Optional vacuum holder system available for added convenience.

Flap Wheels: Equipped with high-performance flap wheels (Ø300 x 600 mm) to effectively remove burrs and round edges, improving the surface finish.

Adjustable Feeding Speed: Tailored to the specific requirements of your metal parts, providing flexibility and efficiency.

Dust Extraction: Optional dust extraction system ensures a cleaner working environment and complies with safety standards.